Method for controlling shape of low-alloy high-strength steel plate in controlled cooling phase

A low-alloy, high-strength, controlled cooling technology, applied in the field of metallurgy, can solve problems such as the unevenness of the steel plate that cannot meet the product quality requirements, fail to meet the product quality requirements, and economic losses to the enterprise, and achieve excellent plate shape, high degree of automation, Improve the effect of regular benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

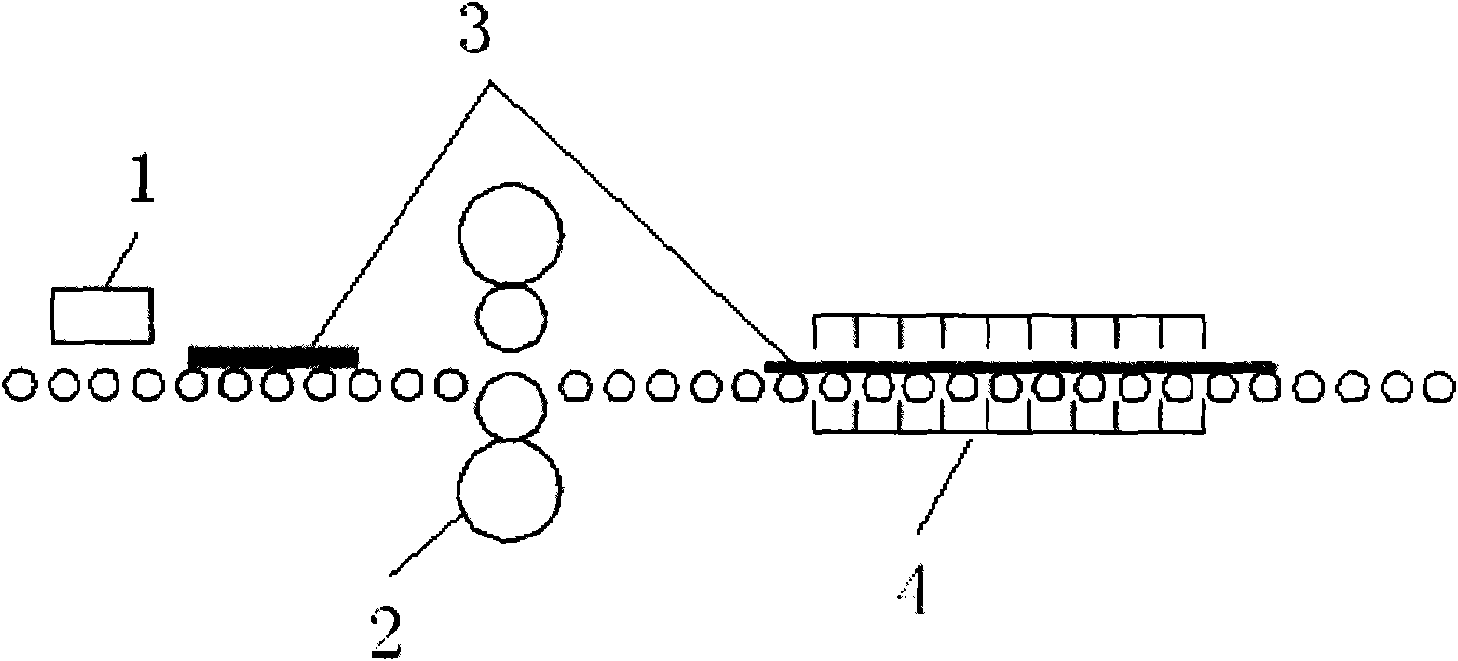

[0021] A method for controlling the plate shape of the low-alloy high-strength steel plate in the controlled cooling stage of the present invention, the method adopts the controlled cooling process to obtain the plate shape after rolling in the controlled rolling and controlled cooling process of steel plate production, and according to the plate shape of the rolled plate Adjust the ratio of upper and lower water in the steel plate cooling process, edge shielding and the speed of the steel plate passing through the cooling zone to control the plate shape of the steel plate after cooling, and obtain a low-alloy high-strength steel plate that meets the requirements. The cooling process includes starting and cooling temperature, Final cooling temperature, cooling rate. Specific steps are as follows:

[0022] 1) The starting cooling temperature is controlled at 780-830°C, the final cooling temperature is controlled at 250-600°C, and the cooling rate is controlled at 5-25°C / s to en...

Embodiment 2

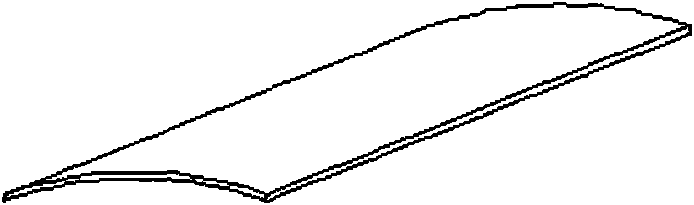

[0027] like Figure 2b , 2d After the steel plate passes through the controlled cooling system, the steel plate is concave along the width direction and the head is tilted. Since the phase change of the upper and surface of the steel plate is not uniform during the cooling process, according to the phase change volume change, that is, martensitic structure > bainite structure > Pearlite structure > ferrite structure; phase transformation temperature changes, that is, martensite structure < bainite structure < pearlite structure < ferrite structure; Surface phase change, by reducing the flow rate on the lower surface of the steel plate or increasing the flow rate on the upper surface, accelerating the phase change on the upper surface or reducing the phase change on the lower surface, a good plate shape can be obtained.

Embodiment 3

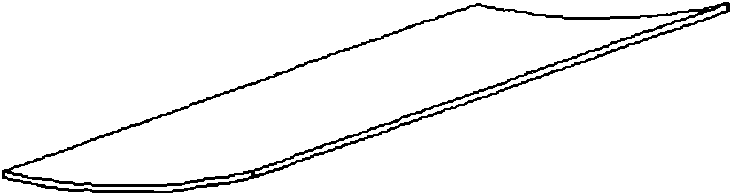

[0029] like Figure 2c After the steel plate passes through the controlled cooling system, the steel plate has side waves along the length direction. Since the upper and surface phase changes of the steel plate are not uniform during the cooling process, according to the phase change volume change, that is, martensitic structure > bainite structure > pearlite structure >Ferrite structure; phase transition temperature changes, that is, martensite structure<bainite structure<pearlite structure<ferrite structure; The phase change at the edge and the edge is not uniform, and 50-100 mm along the edge of the steel plate is used to ensure that the phase change at the middle and edge of the steel plate is not uniform, so as to obtain a good plate shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com