A backing plate for PCB drilling and manufacturing method thereof

A manufacturing method and backing plate technology, which is applied in the field of PCB processing and manufacturing, can solve the problem that the backing plate for drilling cannot be applied to high-grade PCB boards, and achieve the effects of small deformation rate, reduced brittleness, and reduced frictional heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

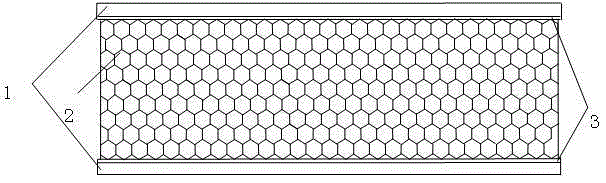

[0021] The invention provides a backing plate for PCB drilling, such as figure 1 As shown, the backing plate includes: a honeycomb core material layer 2, and a hardness panel layer 1 arranged on the upper surface and the lower surface of the honeycomb core material layer.

[0022] The hardness panel layer 1 is formed by hot-pressing single-layer or multi-layer special paper after being superimposed and immersed in resin glue; the special paper is balance paper, wood pulp paper, kraft paper or non-plant fiber material.

[0023] Non-plant fiber materials include non-woven fabrics, glass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com