Method for modifying surface of palygorskite by phosphoric acid and fatty acid

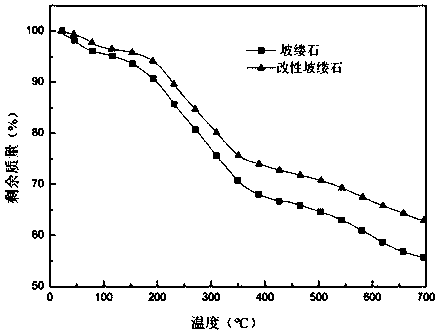

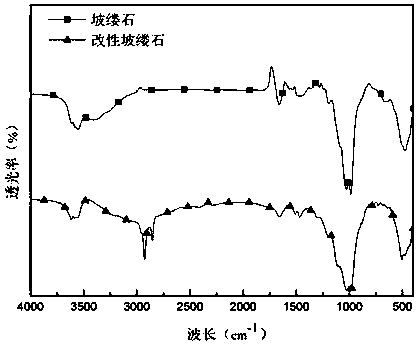

A technology of fatty acid modification and palygorskite, applied in the surface modification of palygorskite, using phosphoric acid and fatty amine to modify the surface of palygorskite, which can solve the problems of insufficient mechanical properties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Disperse 3g phosphoric acid in 150mL absolute ethanol, at 70 o Stir at C for 5min; add 30g palygorskite, stir for 2h; add 3g dodecylamine, stir for 3h; then filter and centrifuge while hot, wash with hot ethanol for many times, and finally vacuum dry in a 60°C oven to obtain the modified slope rayonite.

Embodiment 2

[0028] Disperse 3g phosphoric acid in 150mL absolute ethanol, at 70 o Stir at C for 8min; add 30g palygorskite, stir for 3h; add 3g dodecylamine, stir for 4h, then filter and centrifuge while hot, wash with hot ethanol for many times, and finally vacuum dry in a 60°C oven to obtain the modified slope rayonite.

Embodiment 3

[0030] Disperse 6g phosphoric acid in 150mL absolute ethanol, stir at 70°C for 5min; add 30g palygorskite, stir for 2h; add 3g dodecylamine, stir for 3h, then filter and centrifuge while hot, wash with hot ethanol for many times, and finally The modified palygorskite was obtained by vacuum drying in an oven at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com