Hole punching device for carbon dioxide buffer silicon wafer

A carbon dioxide and hole punching device technology, applied in the field of silicon wafer etching, can solve the problems of poor line width control, device damage, low sidewall smoothness, etc., and achieves improved development and development, overcoming expensive equipment and good sidewall smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

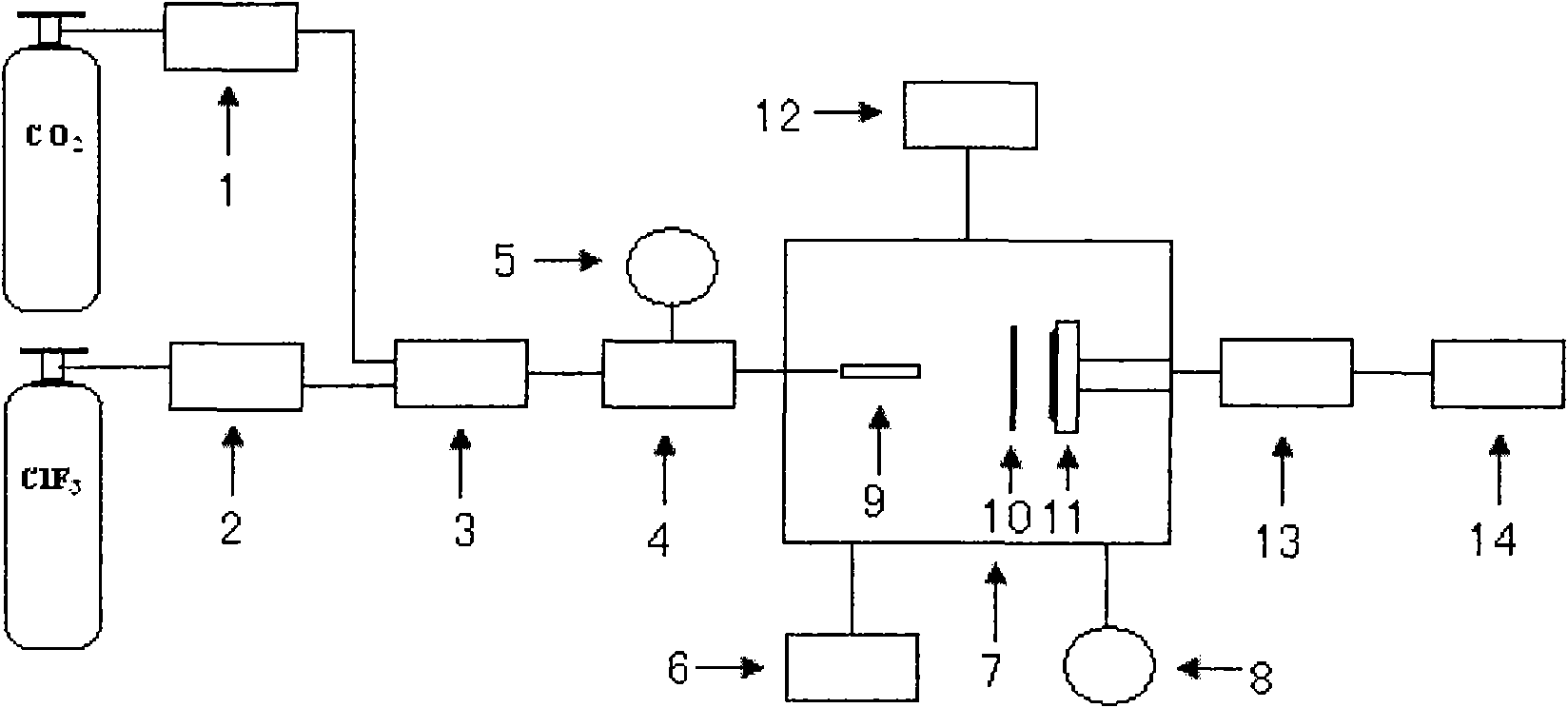

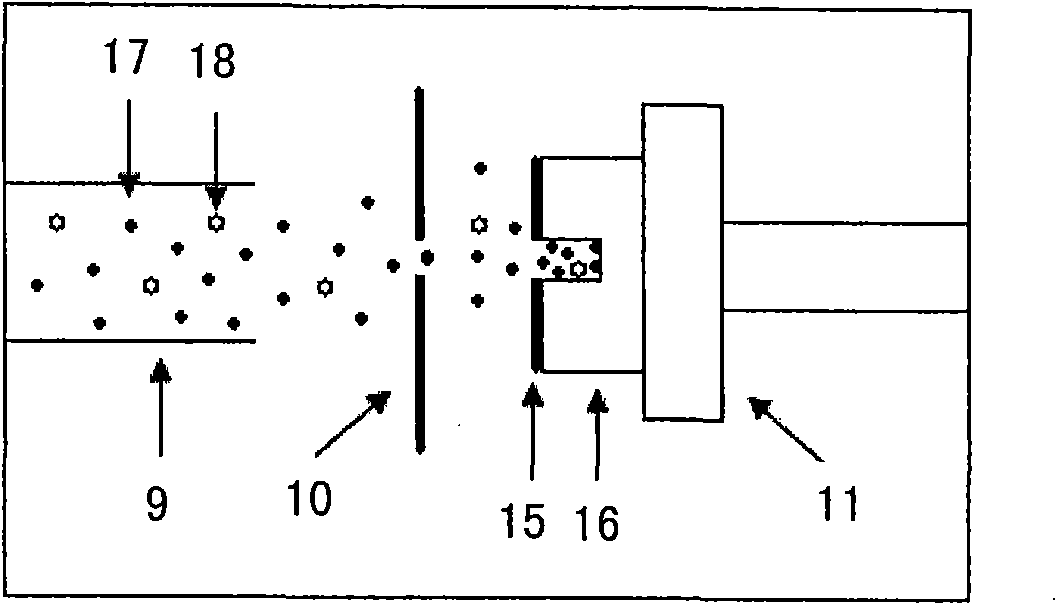

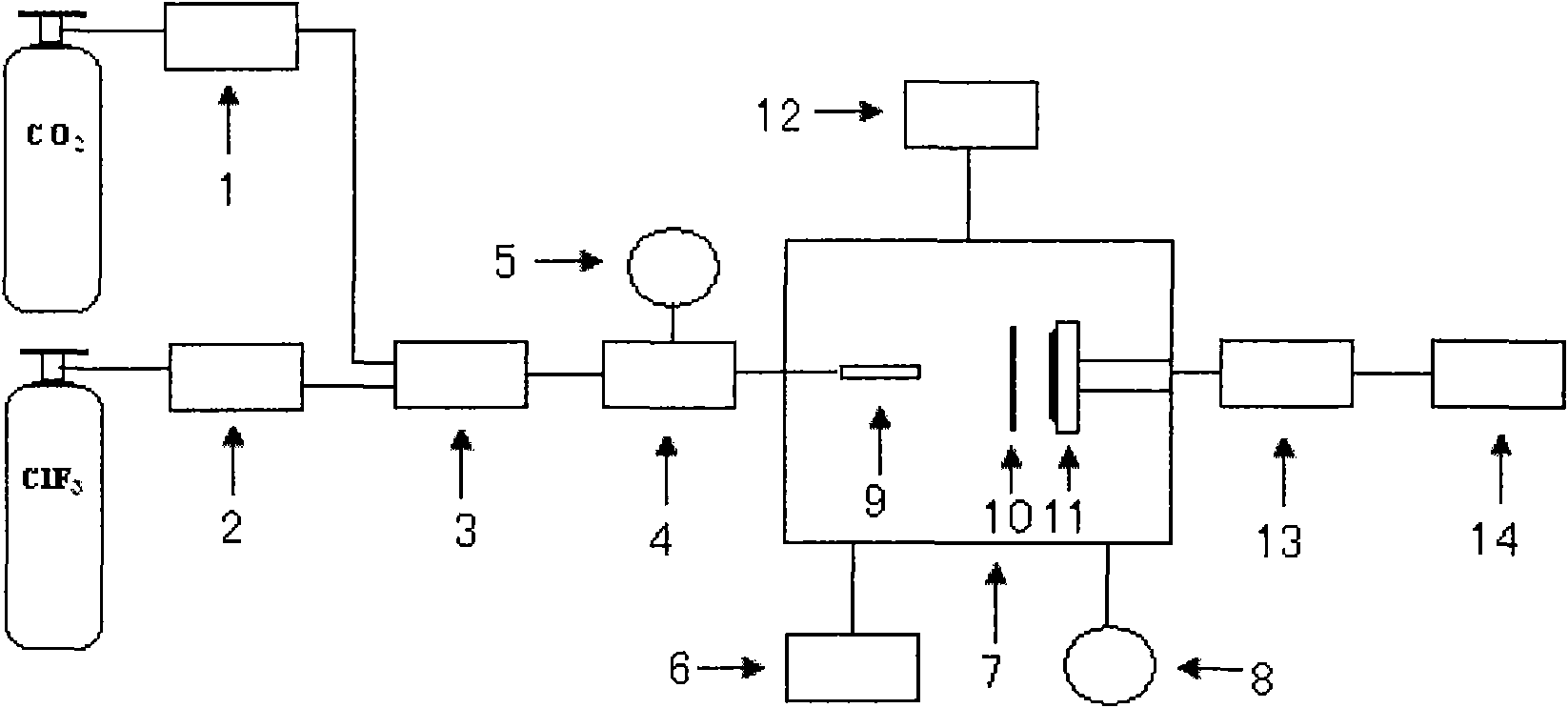

[0020] The carbon dioxide buffered silicon chip punching device provided by the present invention adopts chlorine trifluoride as the etching reaction gas, and the carbon dioxide acts as a buffering regulator. Chlorine trifluoride etching of silicon wafers is carried out in a plasma-free environment. Compared with traditional RIE and ICP etching, this etching system has simple equipment, faster etching rate, and can drill oblique holes at any angle. , and the steepness and smoothness of the side wall are greatly improved. Carbon dioxide is used as a buffer agent, on the one hand, to adjust the gas mixing ratio in the gas path, and improve safety; on the other hand, carbon dioxide is easy to form dry ice when it is rapidly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com