High-reliability and low-viscosity underfill

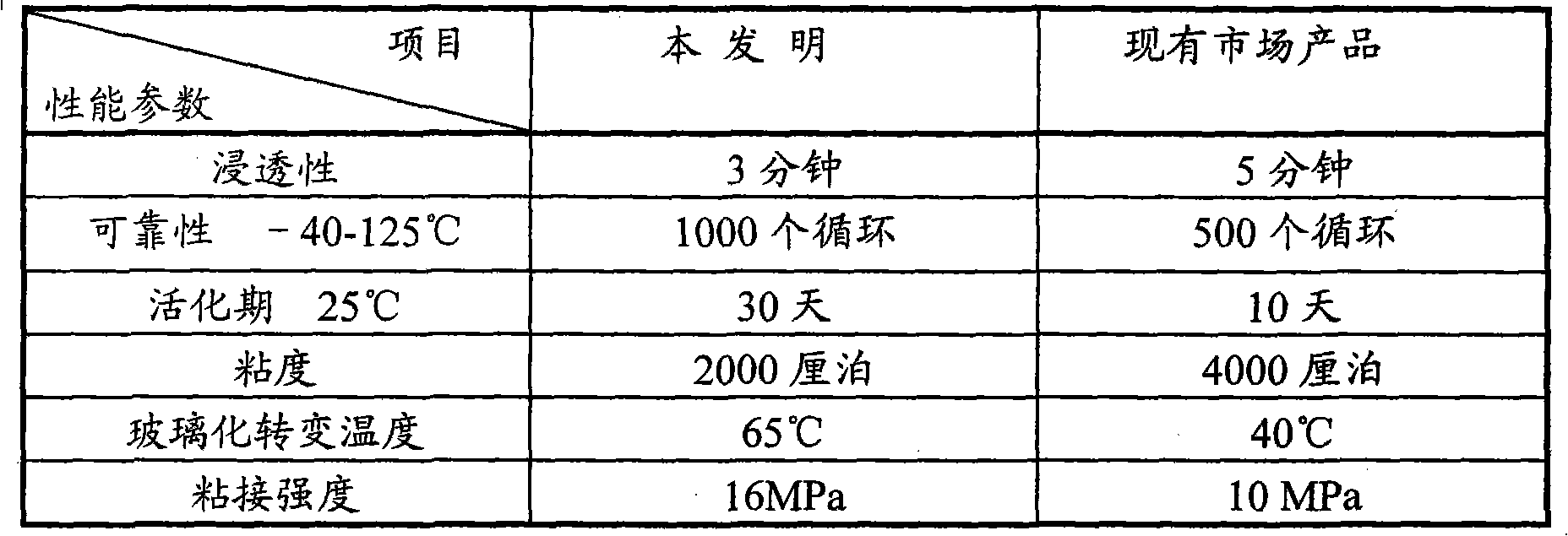

An underfill and reliability technology, used in non-polymer adhesive additives, adhesives, epoxy resins, etc., can solve the problems of reducing inorganic fillers, increasing linear expansion coefficient, reducing reliability, etc., to enhance flow performance, inhibiting precipitation, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment is configured by the following raw materials in weight percentage:

[0038] Bisphenol F type epoxy resin: 12.8%

[0039] Cycloaliphatic epoxy resin: 11.4%

[0040] Dicyclopentadiene type epoxy resin: 13%

[0041] Methyltetrahydrophthalic anhydride: 40%

[0042] PN-23 amine curing accelerator: 0.86%

[0043] Spherical silica powder: 21.9%

[0044] 3-Aminopropyltriethoxysilane: 0.04%

[0045] Carbon black: 0%

Embodiment 2

[0047] The present embodiment is configured by the following raw materials in weight percentage:

[0048] Bisphenol F type epoxy resin: 0%

[0049] Cycloaliphatic epoxy resin: 62.5%

[0050] Dicyclopentadiene type epoxy resin: 0.44%

[0051] Methylhexahydrophthalic anhydride: 11.4%

[0052] HX-3788 amine curing accelerator: 0.86%

[0053] Spherical silica powder: 16.4%

[0054] 3-Aminopropyltriethoxysilane: 4.2%

[0055] Carbon black: 4.2%

Embodiment 3

[0057] The present embodiment is configured by the following raw materials in weight percentage:

[0058] 828 epoxy resin: 2.5%

[0059] Cycloaliphatic epoxy resin: 30%

[0060] Dicyclopentadiene type epoxy resin: 1%

[0061] Methylhexahydrophthalic anhydride: 13%

[0062] PN-23 amine curing accelerator: 1%

[0063] Spherical silica powder: 51.1%

[0064] 3-Aminopropyltriethoxysilane: 0.9%

[0065] Carbon black: 0.5%

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com