Corrosion resistant coating for metal magnesium and preparation method thereof

A metal magnesium and corrosion-resistant technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of reduced coating protection function, uneven corrosion, etc., and achieve long protection time, simple preparation process and operation, The effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

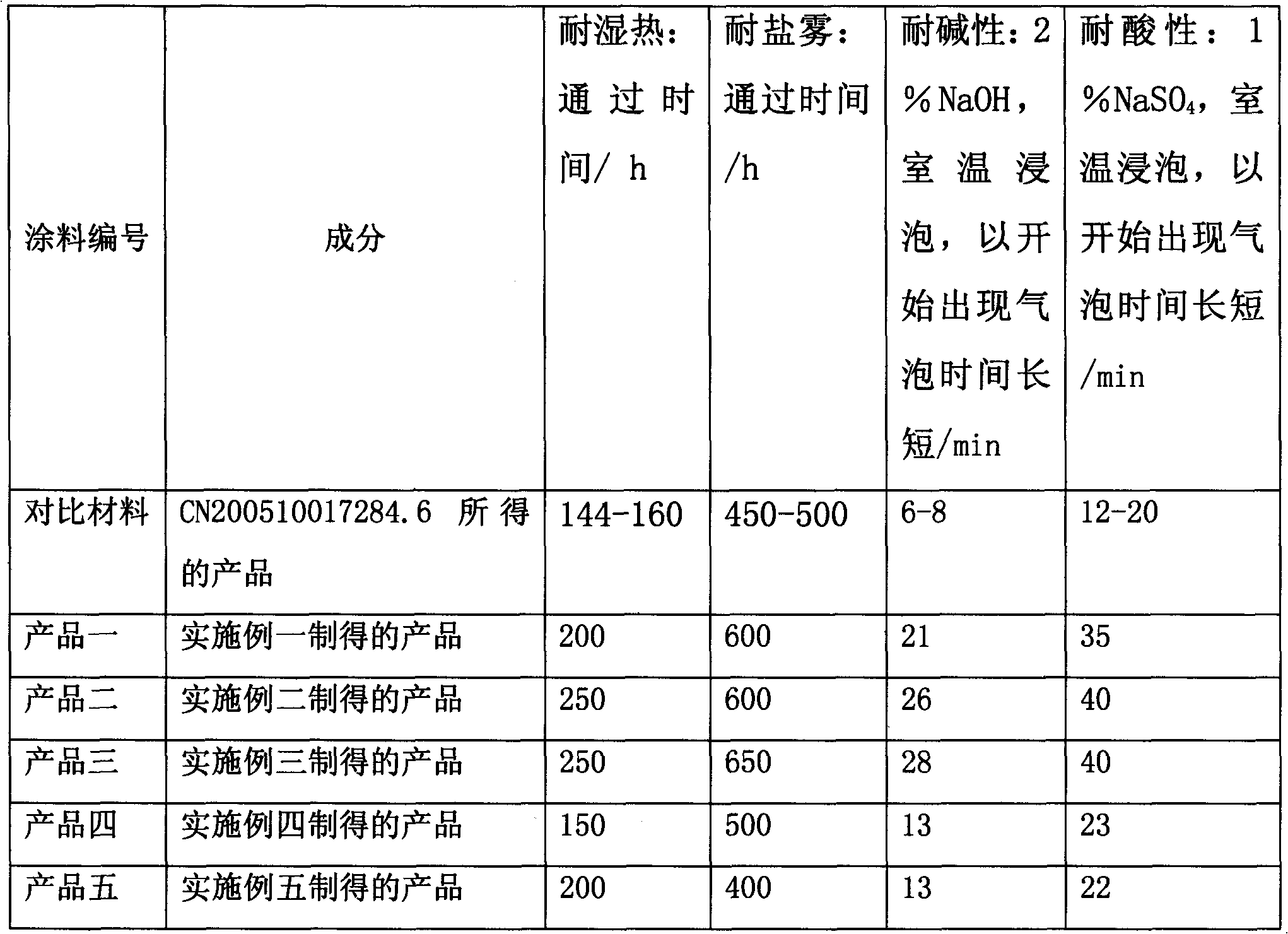

Embodiment 1

[0026] The preparation process of corrosion-resistant paint for magnesium alloy of the present invention is as follows:

[0027] Preparation of alloy powder: according to weight percentage: Cu is 2%, Sn is 0.01%, Sb is 0.2%, Si is 3%, Pr is 0.03%, and the rest is Ni for batching, wherein Sn and Sb are made of pure metal Ingots, pure cadmium grains for Cd, pure plates for Cu and Ni, silicon blocks for Si, and praseodymium-aluminum intermediate alloys containing Pr15% for Pr; the raw materials are put into a crucible with a bottom hole equipped with an induction coil and heated and melted. The diameter of the hole is 1-2mm. The lower part of the bottom hole of the crucible is equipped with a rotating molybdenum alloy runner. The upper part of the crucible is connected to a nitrogen pressure system. The melting is carried out under normal pressure. The induction coil plays the role of heating and melting the alloy. The temperature is 1700-1720°C (the temperature can only be heate...

Embodiment 2

[0030] Preparation of the alloy powder: the weight percentage of the chemical composition of the alloy powder is: Cu is 4%, Sn is 0.1%, Sb is 0.4%, Si is 6%, Pr is 0.09%, and the rest is Ni.

[0031] The percentage by weight of each component during coating preparation is: 45% alloy powder, 6.0% titanium carbonitride powder, 6% silicon nitride powder, 8.0% butanol, and the rest is epoxy resin liquid;

[0032] The preparation process is the same as in Example 1.

Embodiment 3

[0034] Preparation of the alloy powder: the weight percentage of the chemical composition of the alloy powder is: Cu is 3%, Sn is 0.09%, Sb is 0.3%, Si is 4%, Pr is 0.06%, and the rest is Ni.

[0035] The percentage by weight of each component during coating preparation is: 42% alloy powder, 5% titanium carbonitride powder, 5% silicon nitride powder, 7.5% butanol, and the rest is epoxy resin liquid;

[0036] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com