Electromagnetic shielding polymeric material

A technology of electromagnetic shielding and polymeric materials, which is applied in the field of functional polymeric materials, can solve the problems of difficult material production and processing, high filling rate, and poor physical properties of materials, and achieve good electromagnetic shielding effect, easy injection molding, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

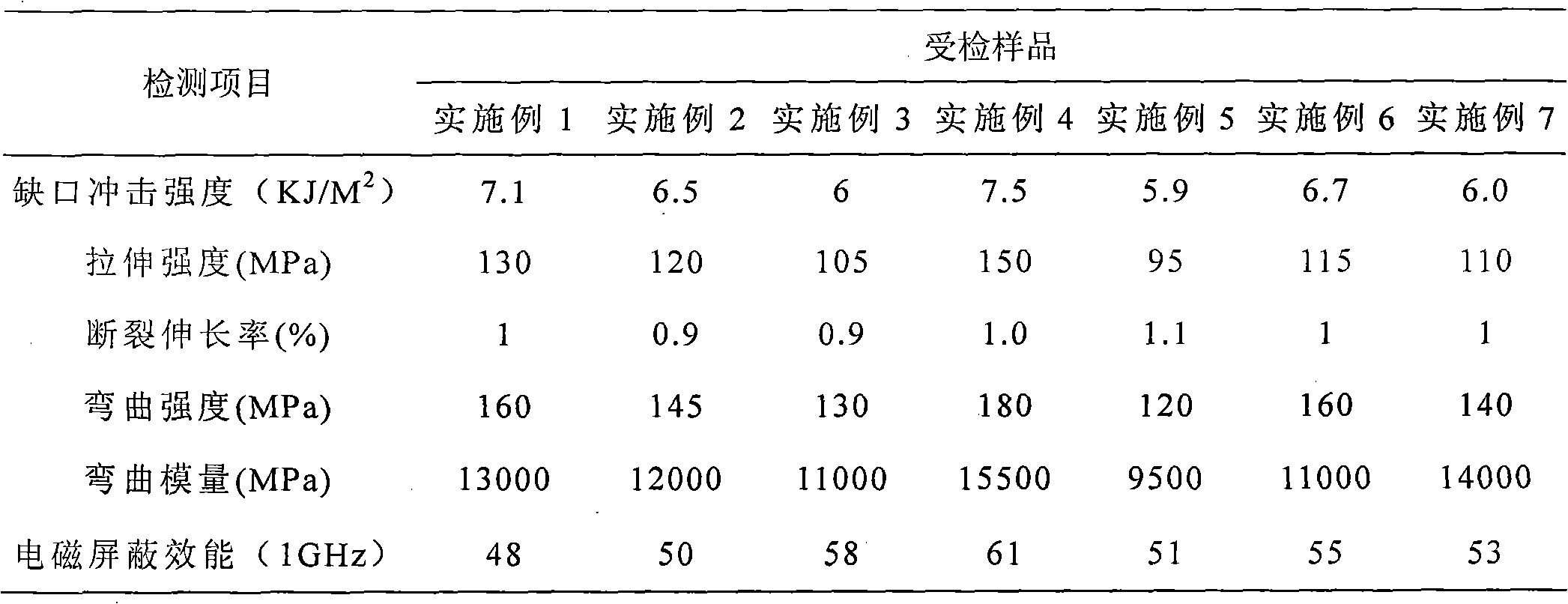

Examples

preparation example Construction

[0018] The preparation method of polyamide electromagnetic shielding masterbatch comprises:

[0019] 1) After immersing the chopped nickel-plated stainless steel fiber in titanate coupling agent diluent for 10-20 min, take out the chopped nickel-plated stainless steel fiber and dry it;

[0020] 2) Mix polyamide, treated chopped nickel-plated stainless steel fiber and conventional additives, extrude and granulate to obtain polyamide electromagnetic shielding masterbatch.

[0021] The polyamide electromagnetic shielding masterbatch contains 40-75% by weight of chopped nickel-plated stainless steel fibers, the diameter of the chopped nickel-plated stainless steel fibers is 8-12 μm, and the length is 8-12 mm.

[0022] The preparation method of the electromagnetic shielding polymeric material of the present invention is as follows:

[0023] Mix the electromagnetic shielding aid and coupling agent uniformly at 50-80°C, then add polyphenylene sulfide, polyamide electromagnetic shiel...

Embodiment 1

[0028] The electromagnetic shielding polymeric material contains the following parts by weight:

[0029] 100 parts of polyphenylene sulfide;

[0030] 100 parts of polyamide electromagnetic shielding masterbatch, polyamide electromagnetic shielding masterbatch contains 66% chopped nickel-plated stainless steel fiber;

[0031] Electromagnetic shielding additive 70 parts, composed of 400 mesh aluminized hollow glass beads;

[0032] 1.5 parts of antioxidant, made up of 0.5 part of hindered phenol antioxidant 1010, 0.5 part of phenolic antioxidant 264 (BHT), 0.5 part of phosphite antioxidant;

[0033] 1.2 parts of titanate coupling agent, composed of chelating pyrophosphate titanate coupling agent CS311;

[0034] 1.5 parts of processing aids, consisting of 0.4 parts of pentaerythritol stearate PETS, 0.3 parts of silicone powder, and 0.8 parts of TAF.

Embodiment 2

[0036] The electromagnetic shielding polymeric material contains the following parts by weight:

[0037] 100 parts of polyphenylene sulfide;

[0038] Polyamide electromagnetic shielding masterbatch 90 parts, polyamide electromagnetic shielding masterbatch contains 75% chopped nickel-plated stainless steel fiber

[0039] 80 parts of electromagnetic shielding additives, consisting of 60 parts of 400-mesh aluminized hollow glass beads and 20 parts of 400-mesh brass powder;

[0040] 1 part of antioxidant, consisting of 0.6 part of phenolic antioxidant 2246 and 0.4 part of metal deactivator MD1024;

[0041] 0.8 parts of titanate coupling agent, consisting of 0.3 parts of pyrophosphate titanate coupling agent CS-201, 0.5 parts of coordination type phosphite titanate coupling agent CS-401;

[0042] 2 parts of processing aids, consisting of 0.8 parts of pentaerythritol stearate PETS, 0.8 parts of silicone powder, and 0.4 parts of calcium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com