Fluorescent discharge lamp tube, and liquid crystal display device

A discharge lamp and fluorescent technology, which is applied to discharge lamps, gas discharge lamps, and parts of gas discharge lamps, etc., can solve the problems of the inability of electrons to emit light at the center and the discharge breakdown of the film layer, so as to achieve low consumption and reduce consumption. Electricity, the effect of improving illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

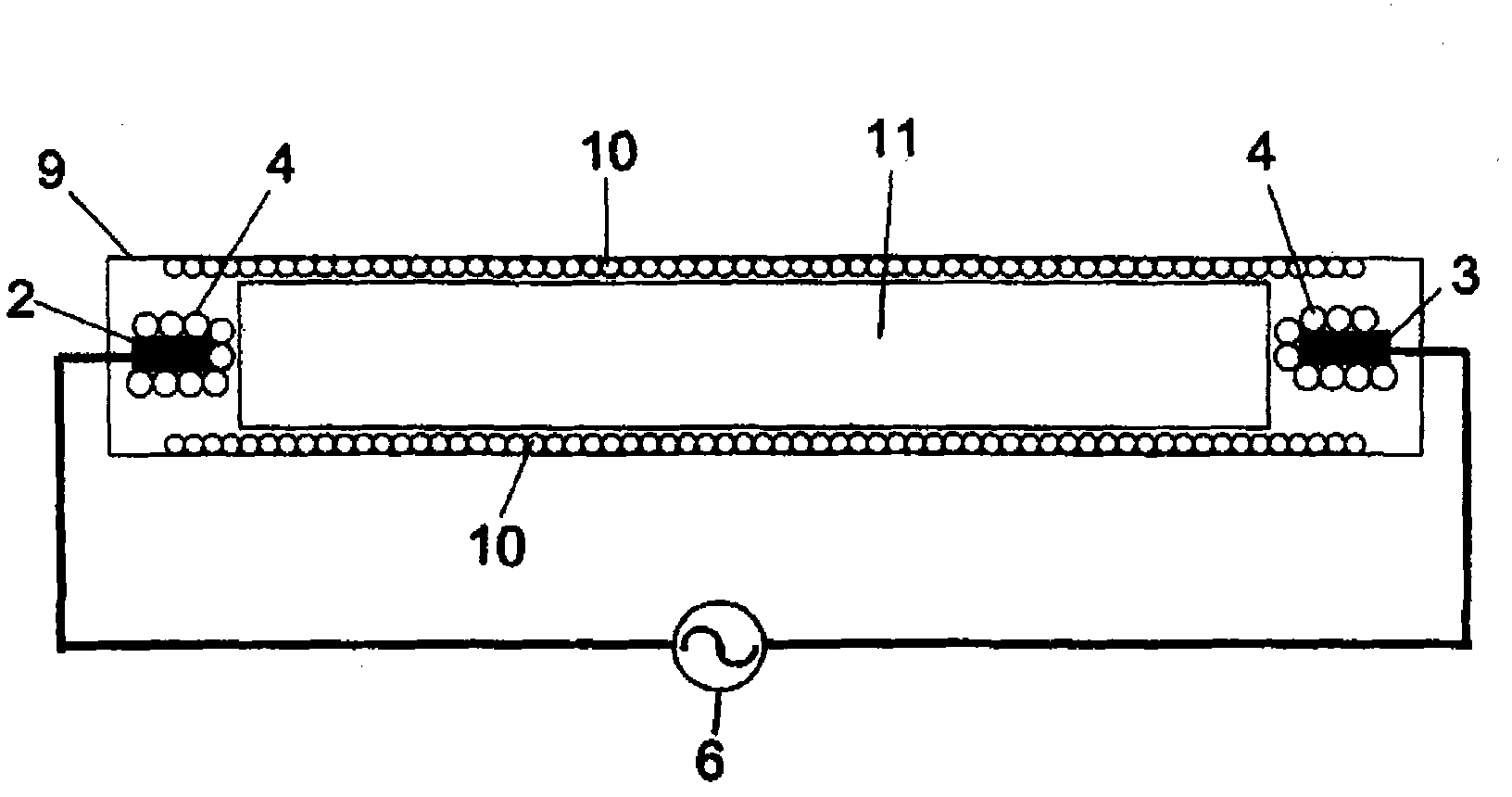

[0158] A component of the electron source of the present invention is to coat the metal electrode with insulator particles at an appropriate thickness. Since the insulator particles are powder, the insulator particles and a binder solution called a vehicle are mixed to prepare a coating liquid (slurry). Commonly used media are the two media shown in Table 1. The same results were obtained regardless of the vehicle used.

[0159] Table 1

[0160] Medium A

[0161] Material

[0162] Choose Y(V,P)O in Ni metal rod electrode 4 : Eu red phosphor powder is used as insulator particles, and vehicle A is used to make a slurry. Table 2 shows the mixing ratio thereof. The materials in Table 2 were accurately weighed with a scale, and the two were thoroughly mixed to prepare a slurry. The Ni metal rod electrode is immersed in the slurry and pulled out immediately, then the surface of the Ni metal rod electrode is attached with the slurry. The number of layers of ...

Embodiment 2

[0164] Choose Y in Ni-Cr disc metal electrode 2 o 3 : Eu red phosphor powder is used as insulator particles, and vehicle B is selected and mixed into a slurry. Table 3 shows the mixing ratios when preparing the slurry. The materials in Table 3 were accurately weighed with a scale, and the two were thoroughly mixed to prepare a slurry. After dipping the Ni-Cr disk-shaped metal electrode in the slurry and pulling it out, the slurry adheres to both surfaces of the Ni-Cr disk-shaped metal electrode. The number of layers of insulator particles attached can be adjusted by changing the mixing ratio shown in Table 3. Since the insulator particle layer on the drawn Ni-Cr disk-shaped metal electrode was wetted with the slurry, it was dried by blowing a slight hot air. After drying, put the electrode into an uncovered furnace and heat it at 550°C for 10-30 minutes, then the organic matter will decompose through oxidation and form water vapor and carbon dioxide gas to diffuse into the...

Embodiment 3

[0168] The BaO insulator particles and the vehicle B were selected for the Ni metal rod electrode to prepare a slurry. Table 4 shows the mixing ratio thereof. The manufacturing steps are the same as those described in Example 1 and Example 2, and therefore descriptions are omitted. The Ni metal rod electrode coated with this white powder can be used as an electrode of CCFL.

[0169] Table 4

[0170] Material

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com