Process using colored mask combined with selective area deposition

A technology of area selection and masking, which is applied in the field of coloring masks, can solve problems such as limited resolution, achieve the effect of reducing the number and omitting the etching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

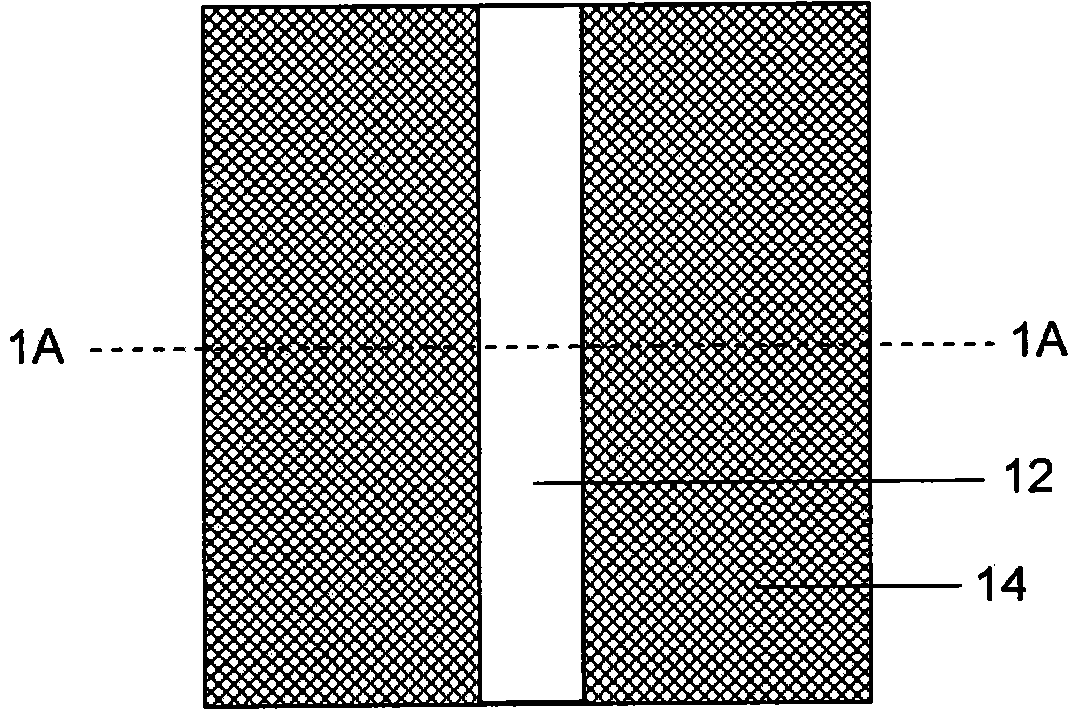

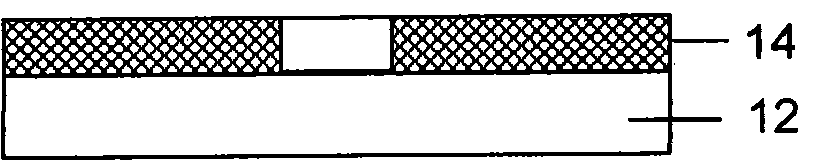

[0266] Example 1: Multicolor Mask Formed by Direct Printing Process

[0267] In this example, a multi-color mask containing three filter layers, each color corresponding to an independent functional layer in the thin film transistor device array, was prepared. Convert the gate layer design of the thin film transistor device array into a black and white bitmap file. Convert the semiconductor layer design of the thin film transistor device array into another black and white bitmap file. Convert the source and drain layer design of the TFT device array into a third black and white bitmap file. These bitmaps were then imported into the blue, green and red channels of a single color image file using Photoshop 6.0. In this full-color image, the blue channel contains the gate design as a yellow pattern. The green channel contains the semiconductor layer design as a magenta pattern. The red channel contains the source and drain designs as cyan patterns. This color image was print...

Embodiment 2

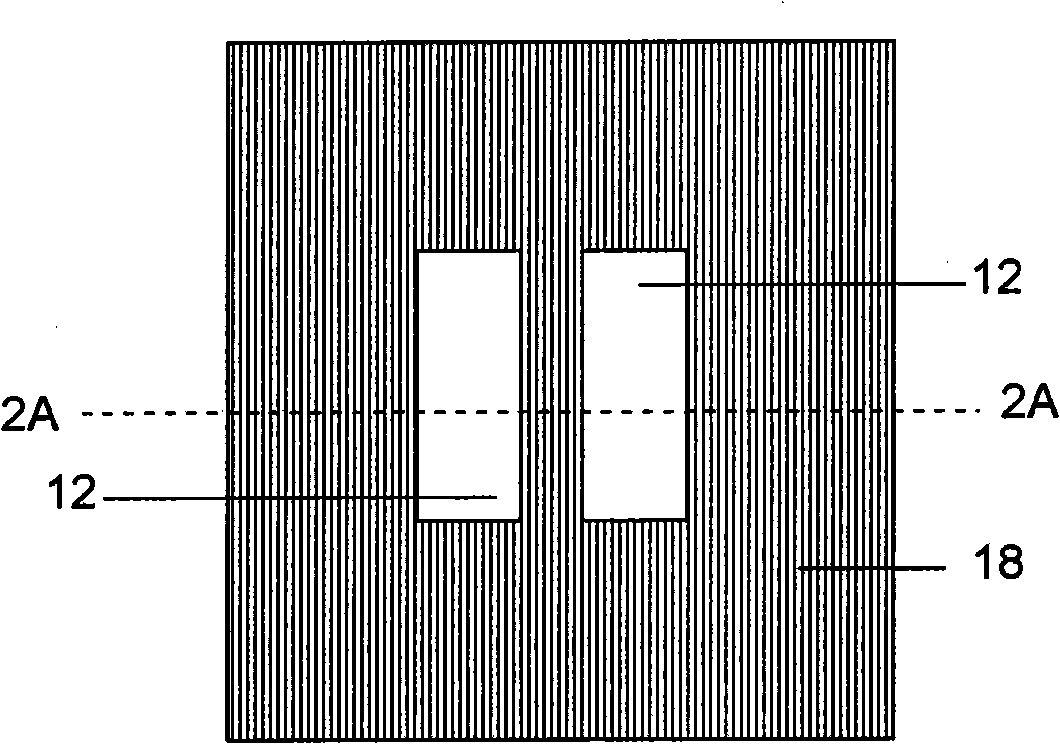

[0268] Example 2: Multicolor Mask Formed by Photolithographic Process

[0269] In this example, a multi-color mask containing three filter layers, each color corresponding to an independent functional layer in the thin film transistor device array, was prepared. Chrome-on-glass masks for the gate (CG-1 ), semiconductor and dielectric (CG-2) and source and drain (CG-3) layers of the thin film transistor device array were obtained from Applied Image Incorporated. A 0.7 mm thick borosilicate glass support was cleaned for 10 minutes by treatment with a solution of 70% sulfuric acid and 30% hydrogen peroxide maintained at about 100°C for 10 minutes. After cleaning, the clean glass was spin-coated (at 1000 RPM) with ColorMosaic SC3200L (available from Fujifilm Electronic Materials Co., Ltd.). SC-3200L is a UV curable photoresist containing 3-5% cyan pigment, 7-9% methacrylate derivative copolymer, 7-9% multifunctional acrylate resin and UV photosensitizer.

[0270] The coated gla...

Embodiment 3

[0272] Embodiment 3: blue light curing film preparation

[0273] Coating solution C-1 for the blue light curable film was prepared as follows. A blue-sensitive photoinitiator solution was prepared by adding 0.03 g of photoinitiator A to 3 g of toluene.

[0274] Photoinitiator A:

[0275]

[0276] In a separate vial, 5 grams of polymethyl methacrylate (PMMA) (MW ~ 75K) was dissolved in 45 g of anisole. A solution of 0.95 g of trimethylolpropyl triacrylate and 0.5 g of the photoinitiator A was added to 2.9 g of the resulting PMMA solution.

[0277] Green light curing film preparation:

[0278] Coating solution C-2 for the green light curable film was prepared as follows. A green-sensitive photoinitiator solution was prepared by adding 0.03 g of photoinitiator B to 3 g of anisole. In a separate vial, 5 grams of polymethyl methacrylate (PMMA) (MW ~ 75K) was dissolved in 45 g of anisole. A solution of 0.95 g of trimethylolpropyl triacrylate and 0.5 g of the photoinitiator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com