Quad flat no-lead (QFN) package image sheet automatic alignment method

An automatic alignment, square and flat technology, applied in the direction of semiconductor/solid-state device testing/measurement, can solve the problems of low processing efficiency, waste of manpower, waste of processing area, etc., and achieve the effect of good alignment accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

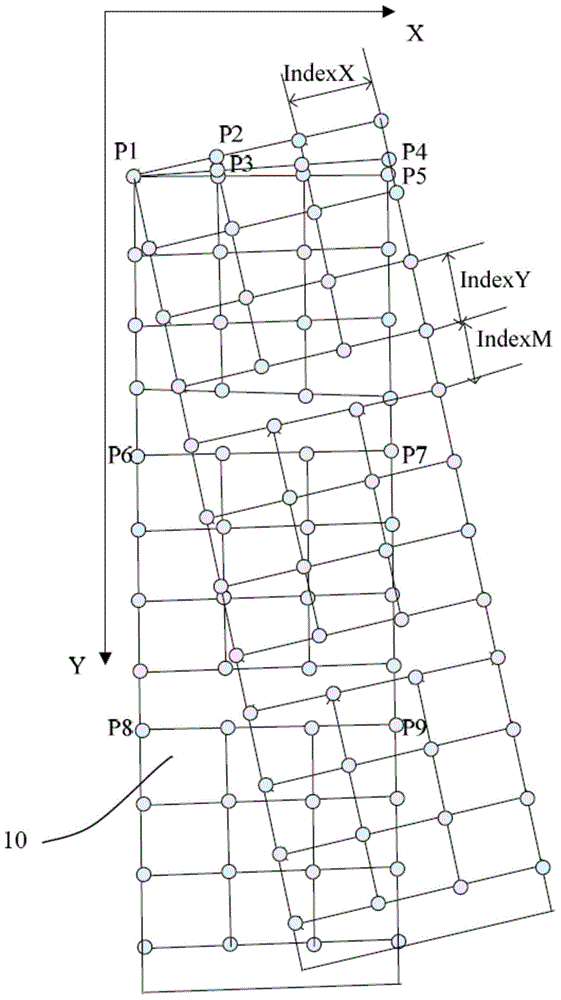

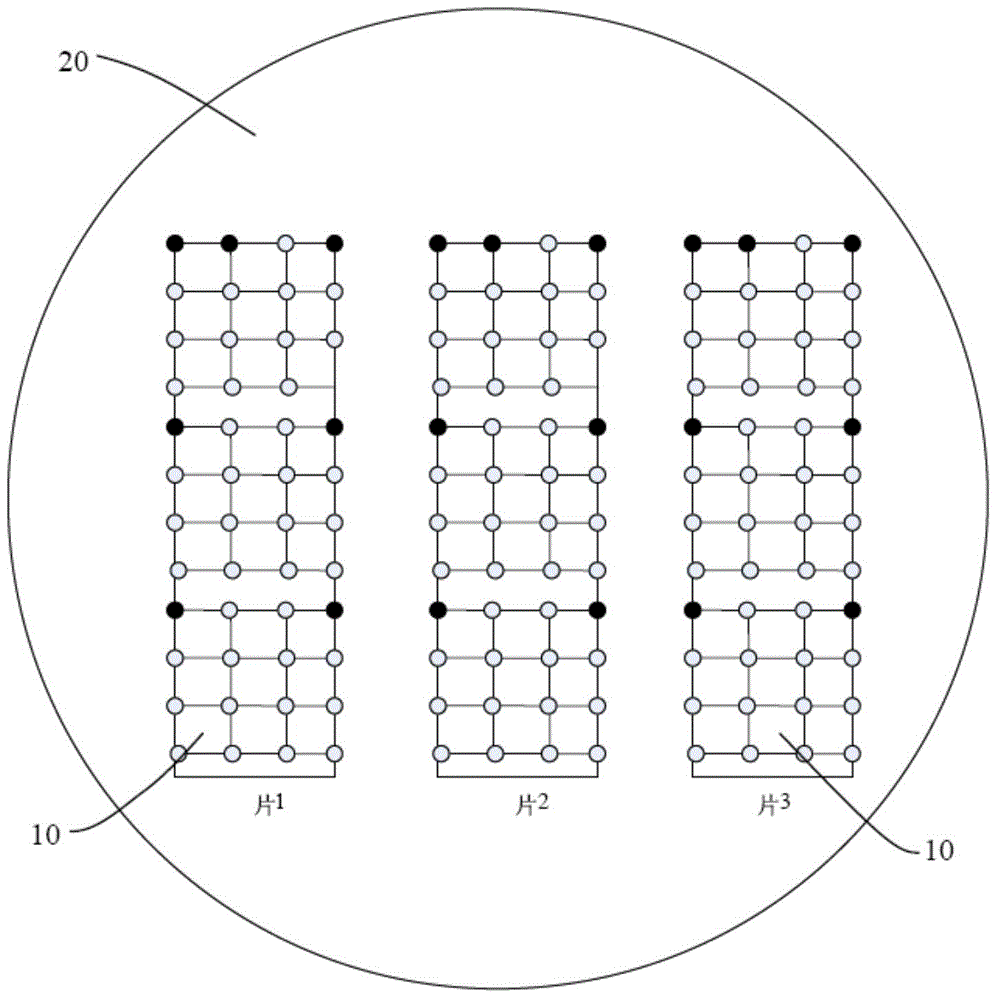

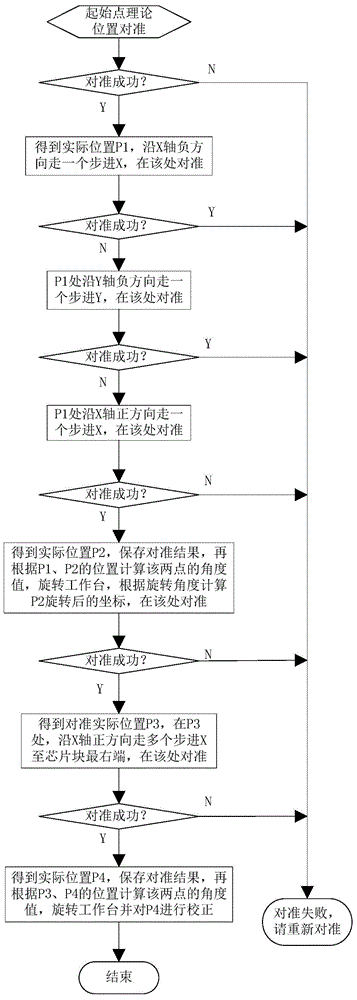

Method used

Image

Examples

Embodiment approach 1

[0053] Embodiment 1 further includes step S7, rotating the table 20 and calculating the rotated coordinates of the P7 point according to the above angle value, aligning the P7 point at the coordinates and saving the alignment result.

Embodiment approach 2

[0054] Embodiment 2 also includes the following steps: S7, at least one step X is taken along the negative direction of the X axis at point P7 to return to point P6, and three steps Y and one step are taken along the positive direction of the Y axis at point P6 Enter M, get the actual alignment position and define it as P8 point, and save the alignment result;

[0055] S8, walk at least one step X along the positive direction of the X-axis at point P8 and perform alignment, obtain the actual alignment position and define it as point P9, and save the alignment result;

[0056] S9, calculate the angle value of these two points according to the position of P8 point and P9 point, and save this angle value;

[0057] S10, equally divide the angle value obtained in step S6 and the angle value obtained in step S9 to each corresponding chip block.

[0058] Specifically, the step S8 is as follows: take three steps X along the positive direction of the X-axis at the point P8 and perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com