Lamp holder assembly fixture and lamp holder assembly method

A technology for assembling fixtures and lamp sockets, which is applied in the directions of hand-held tools, manufacturing tools, workpiece clamping devices, etc., can solve the problems of affecting the production efficiency of lamps, low efficiency, error-prone, etc., and achieves reliable and convenient assembly structure and improves production efficiency. , the effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

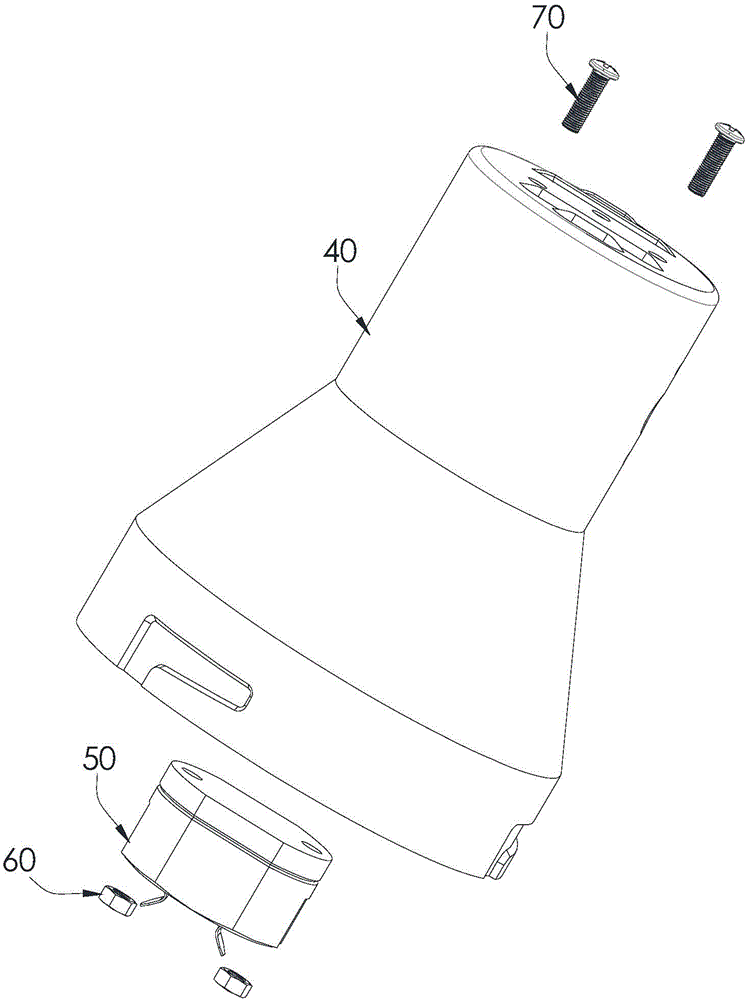

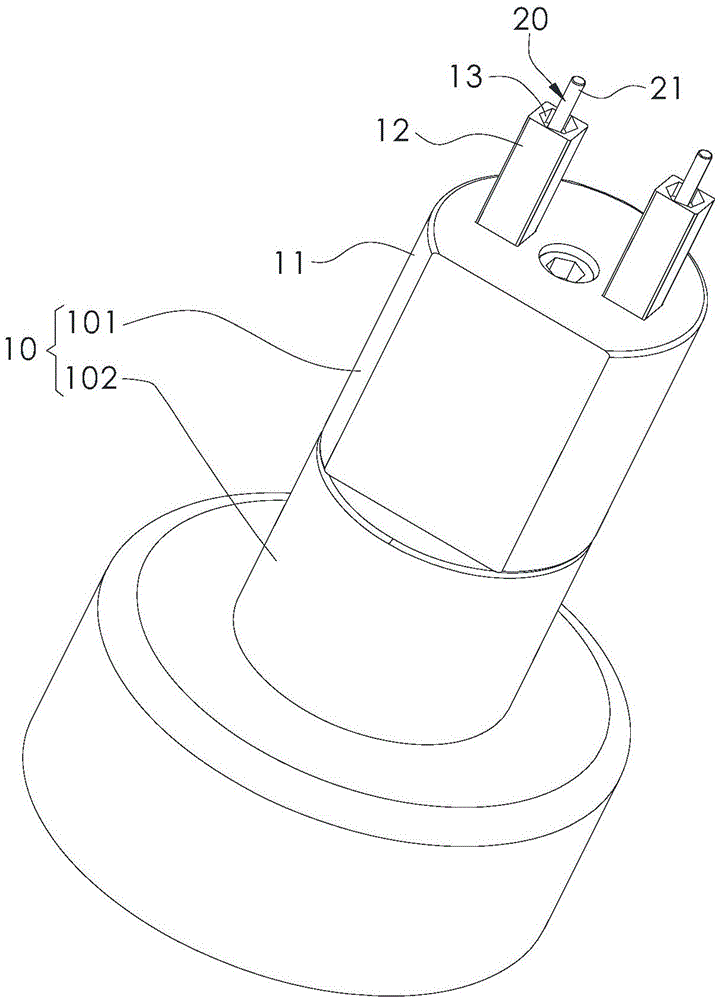

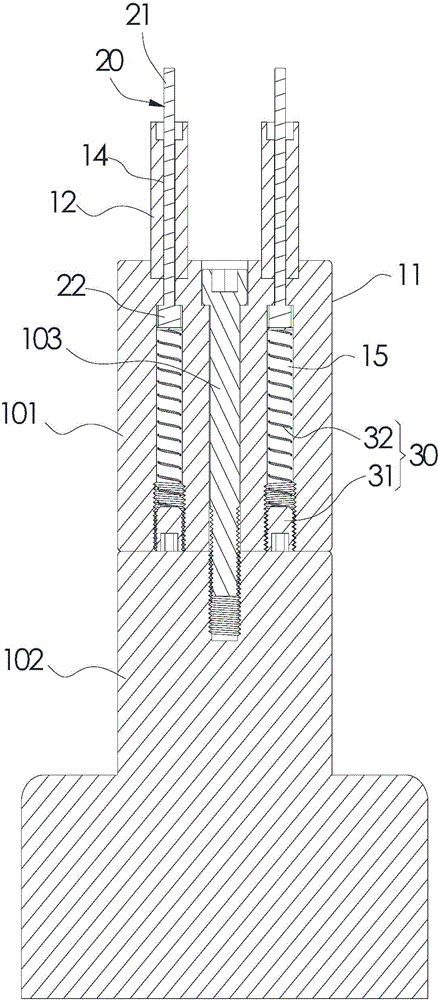

[0027] Such as Figure 2 to Figure 8 As shown, the lamp holder assembly fixture of the present invention includes a mounting base 10, a floating pin 20 and an elastic mechanism 30 for providing the upward elastic support force of the floating pin 20. The positioning end 11 of the positioning end 11 is provided with a lamp cap fixing part 12 for fixing the lamp cap 50, the upper end surface of the lamp cap fixing part 12 is provided with a nut mounting groove 13, and the middle part of the nut mounting groove 13 is provided with a floating needle through hole downward. 14. The floating needle 20 is installed in the floating needle through hole 14, and the upper end of the floating needle 20 is provided with a guide end 21 that can pass through the installation through hole 51 of the lamp cap 50 and the installation through hole 41 of the lamp holder shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com