Systematic detection method for anti-cracking performance of concrete

A detection method and technology of anti-crack performance, applied in the direction of material inspection products, etc., can solve problems such as lack of mature construction technology experience, and achieve the effect of small shrinkage strain, high anti-crack performance, and not easy to fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

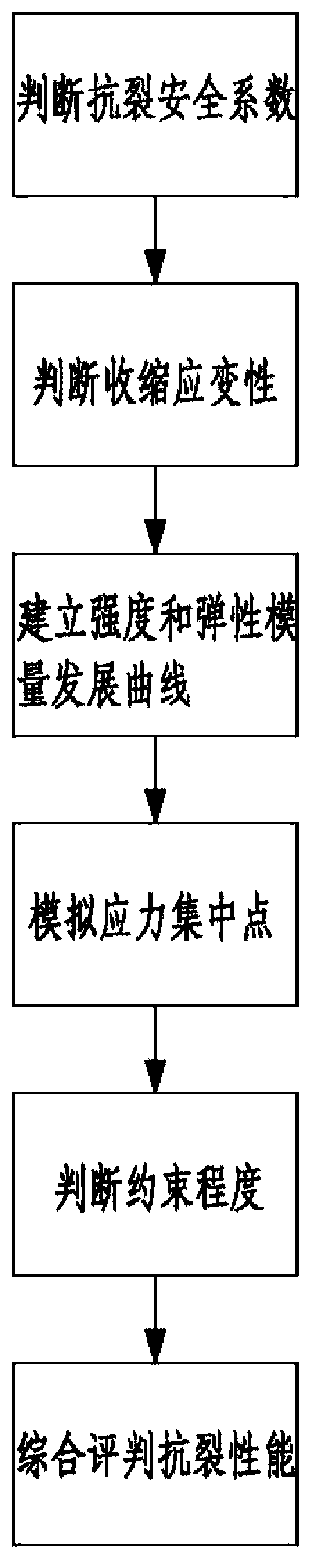

[0060] see figure 1Shown, concrete anti-crack performance systematic detection method of the present invention, described detection method comprises the following steps:

[0061] 1. Detect the temperature and stress parameters of concrete to judge the crack resistance safety factor of concrete:

[0062] Multiple concretes with different proportions were prepared into multiple concrete pastes; the selected concretes were mixed according to their proportions until they were in good condition, and 60L of concrete pastes were made each.

[0063] Each concrete slurry is poured into the mold of the temperature stress testing machine; according to the established test plan, adjust the operating system of the temperature stress testing machine for testing.

[0064] The temperature stress testing machine is controlled to detect the temperature stress parameters of each concrete slurry respectively; the temperature stress parameters include hydration temperature rise, temperature rise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com