Self-aligned process for preparing convex graphical substrate

A self-alignment process and graphic substrate technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as instability, polluted cavity etching process, and expensive exposure machine, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

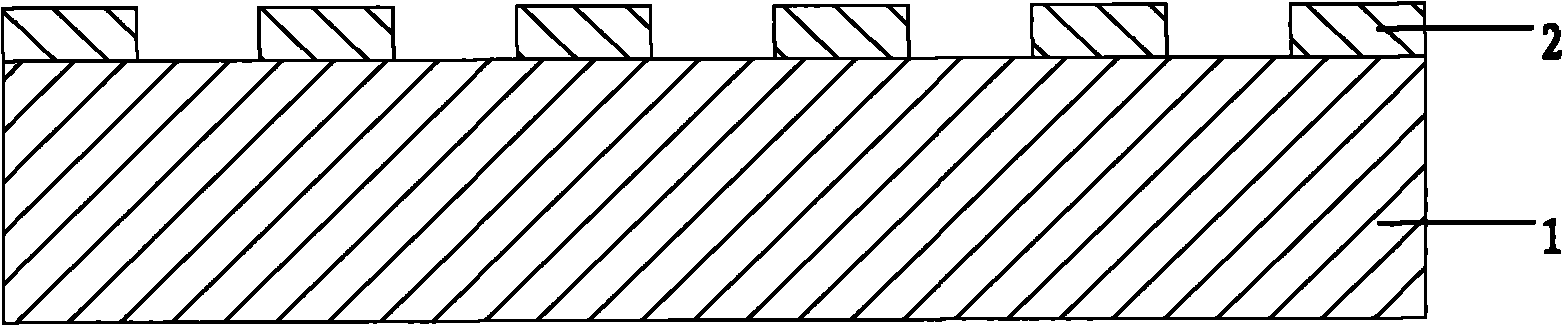

[0029] Step 1, use thinner photoresist on the sapphire substrate to make periodically arranged cylindrical convex pattern microstructures, the height is 0.5um, the maximum width of the cross section is 2um, and the distance between the convex pattern microstructures is 1um.

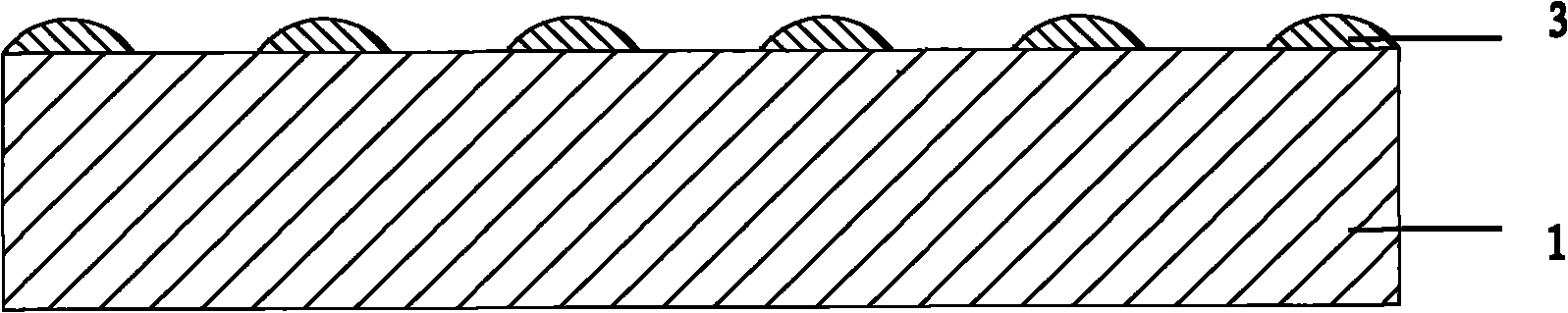

[0030] Step 2, put the sapphire substrate with the convex pattern microstructure into the N 2 High temperature treatment in the atmosphere, the treatment temperature is 450°C, and the treatment time is 10min.

[0031] Step 3: After the high temperature treatment, uniformly coat a photoresist layer with a thickness of 2.5, and perform soft baking.

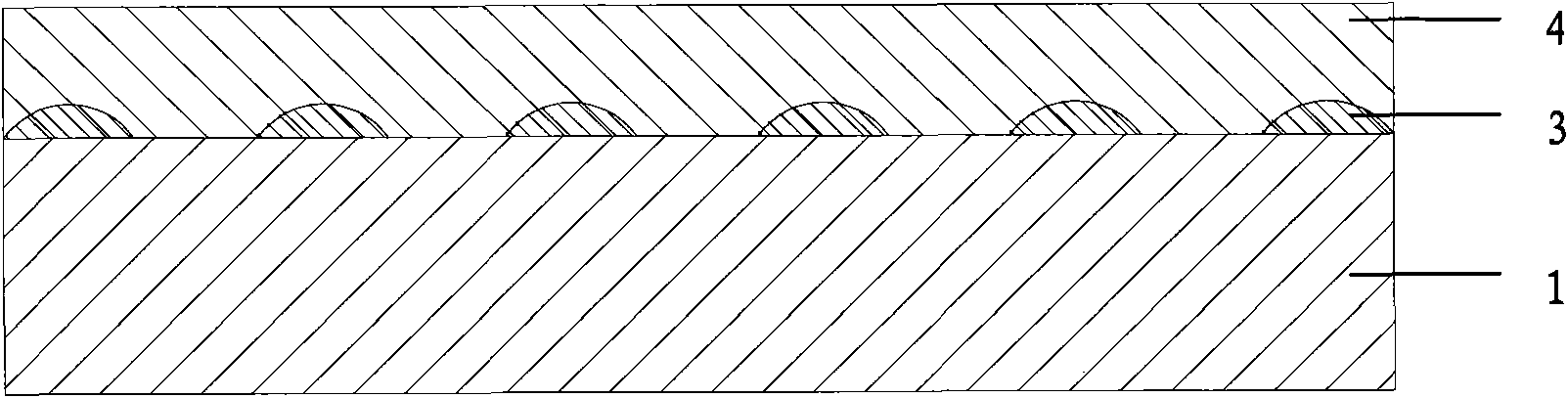

[0032] Then perform self-alignment exposure, development, high-temperature hardening, and fusion in steps 4-6. Finally, the ICP etching technique is used to transfer the pattern structure of the convex round package to the sapphire substrate to obtain a convex pattern substrate that can be used for nitride epitaxial growth.

Embodiment 2

[0034] Step 1. Use a thinner photoresist to make periodically arranged cylindrical convex pattern microstructures on the sapphire substrate. The height is 0.8um, the maximum width of the cross section is 2.5um, and the distance between each convex pattern microstructure 1.5um.

[0035] Step 2, put the sapphire substrate with the convex pattern microstructure into the N 2 High temperature treatment in the atmosphere, the treatment temperature is 600°C, and the treatment time is 30min.

[0036] Step 3: after the high temperature treatment, uniformly coat a photoresist layer with a thickness of 3.2um, and perform soft baking.

[0037] Then perform self-alignment exposure, development, high-temperature hardening, and fusion in steps 4-6. Finally, the ICP etching technique is used to transfer the pattern structure of the convex round package to the sapphire substrate to obtain a convex pattern substrate that can be used for nitride epitaxial growth.

Embodiment 3

[0039] Step 1: On the sapphire substrate, use a thinner photoresist to make periodically arranged conical convex pattern microstructures, the height is 1um, the maximum width of the cross section is 3um, and the distance between the convex pattern microstructures is 2um .

[0040] Step 2, put the sapphire substrate with the convex pattern microstructure into the N 2 High temperature treatment in the atmosphere, the treatment temperature is 800°C, and the treatment time is 50min.

[0041] Step 3: after the high temperature treatment, uniformly coat a photoresist layer with a thickness of 10 um, and perform soft baking.

[0042] Then perform self-alignment exposure, development, high-temperature hardening, and fusion in steps 4-6. Finally, the ICP etching technique is used to transfer the pattern structure of the convex round package to the sapphire substrate to obtain a convex pattern substrate that can be used for nitride epitaxial growth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com