High power microwave plasma diamond film deposition device

A high-power microwave and diamond film technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of hindering microwave input power and limited adjustment of resonant cavity, and achieve easy real-time adjustment, microwave Small energy loss and optimized deposition conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

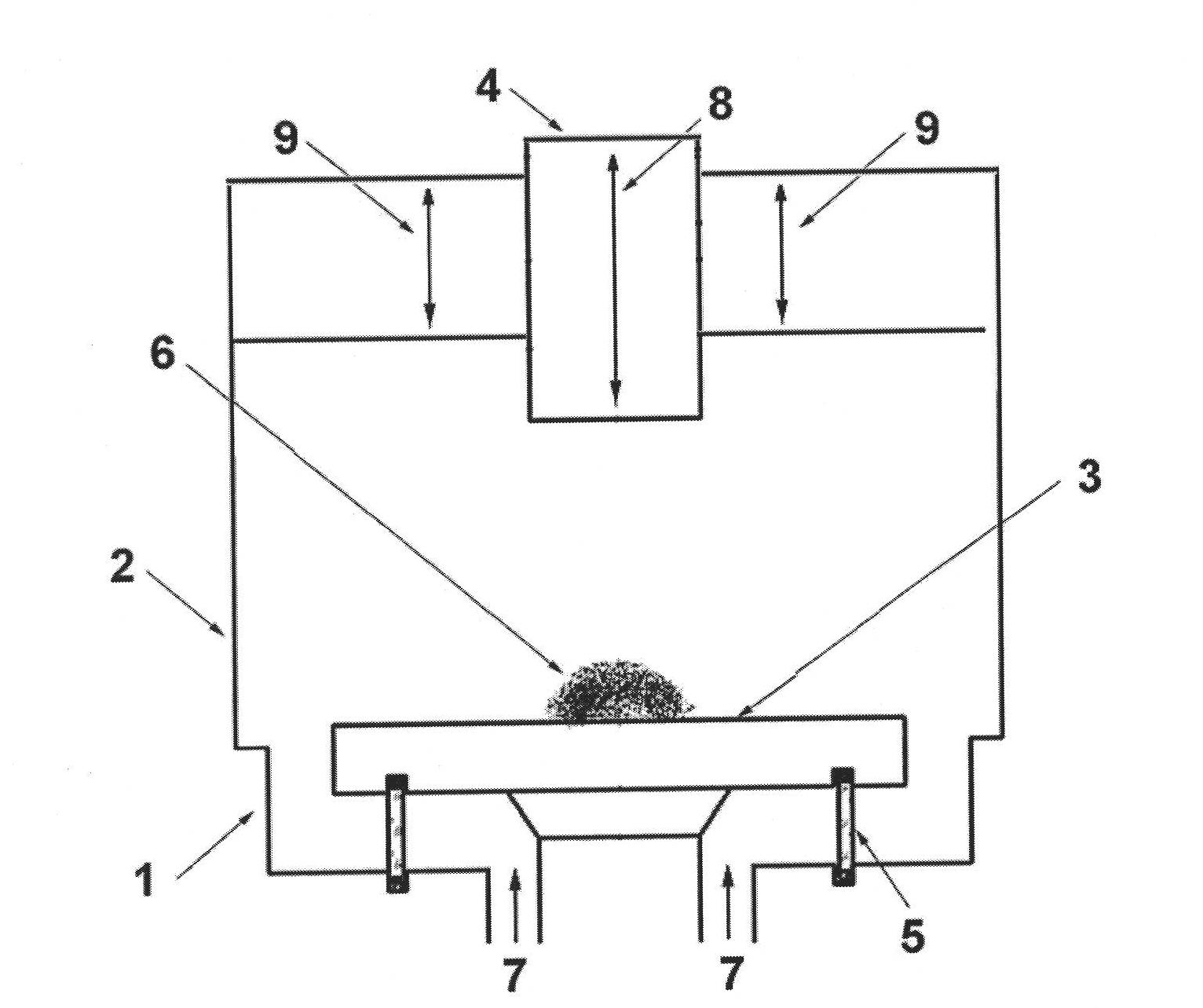

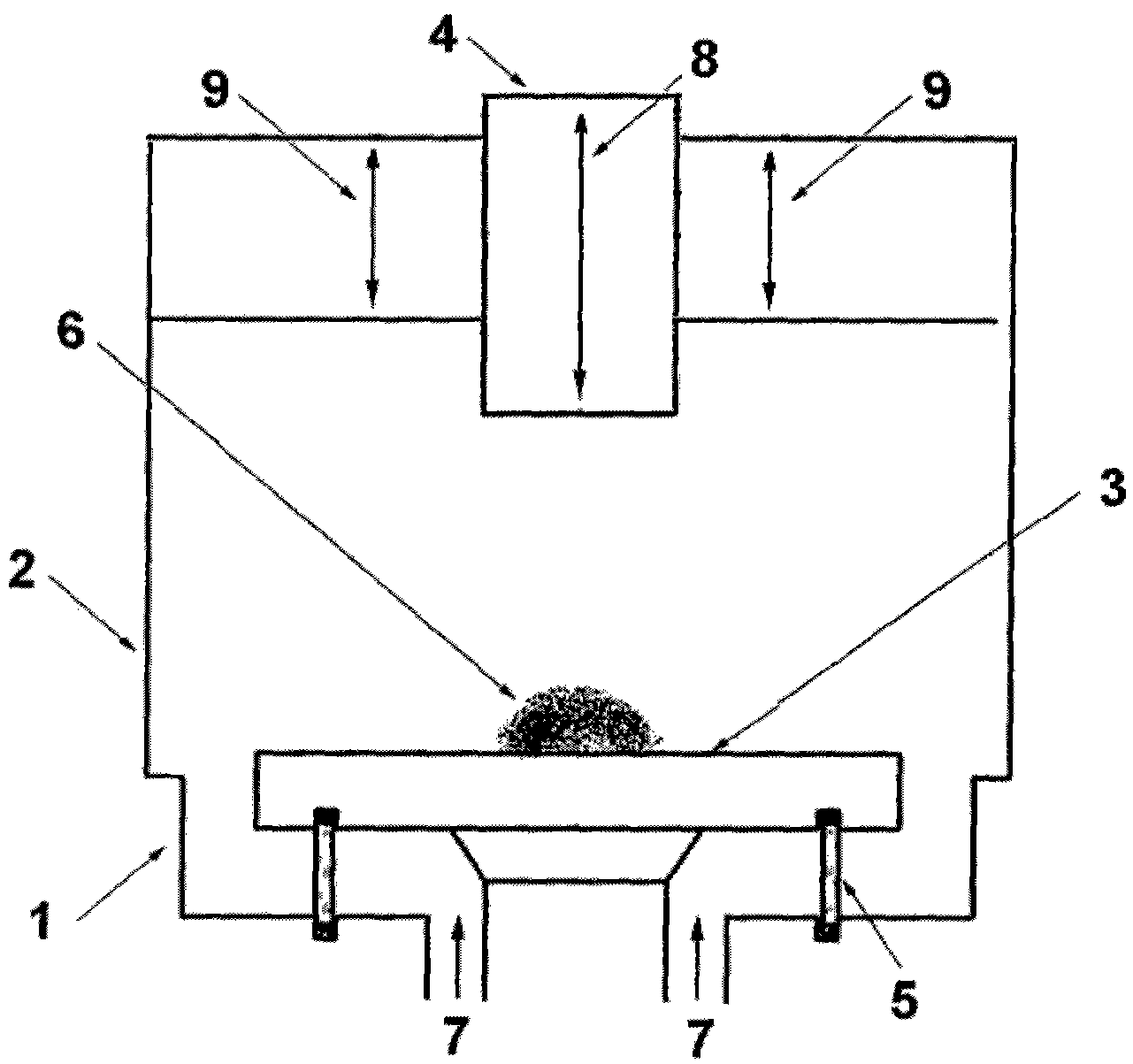

[0029] 1. After the microwave plasma diamond film deposition equipment is evacuated to below 1Pa with a vacuum pump, a mixed gas composed of 98% hydrogen and 2% methane is introduced into the equipment, and the gas pressure is adjusted to 5kPa.

[0030] 2. Pass cooling water to all parts of the equipment that need to be cooled.

[0031] 3. Input 2.45GHz, 1kW microwave power to the equipment to generate plasma in the resonant cavity.

[0032] 4. Adjust the adjustment mechanism of the resonant cavity so that the intensity of the plasma is the strongest, and its position is above the deposition table. At this time, the microwave power reflected back by the resonator also reaches a minimum value.

[0033] 5. Gradually increase the microwave power input to the equipment and the gas pressure to 10kW and 20kPa.

[0034] 6. At the same time, gradually adjust the adjustment mechanism of the resonant cavity, so that the intensity of the plasma is the strongest, and its position is abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com