Method for preparing water soluble quick-acting organic fertilizer from activated sludge

A kind of activated sludge, water-soluble technology, applied in the direction of organic fertilizer, sewage/sludge fertilizer, application, etc., can solve the problems of low output, long compost fermentation cycle, difficult to do topdressing, etc., to achieve short production cycle and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

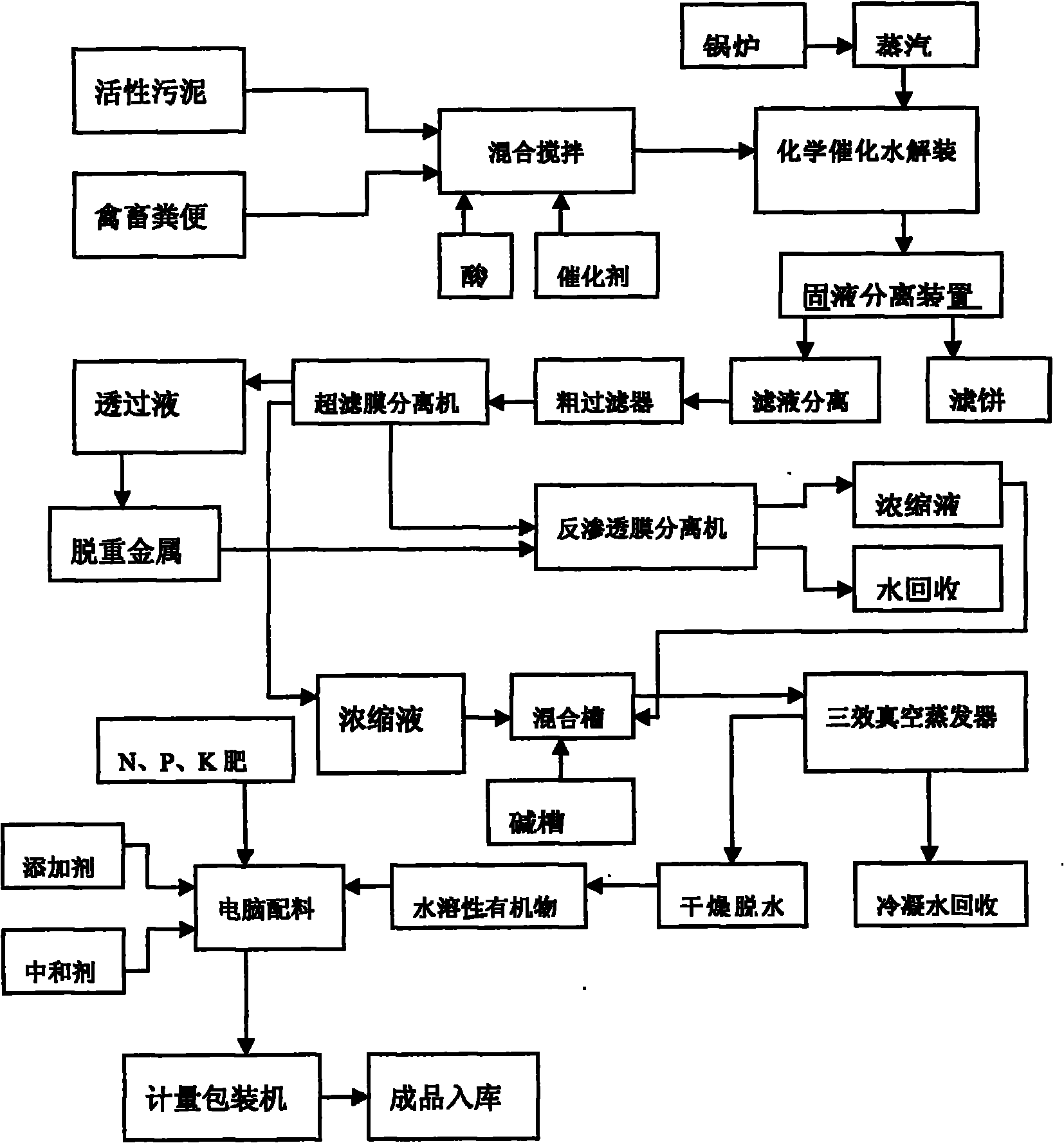

Method used

Image

Examples

Embodiment 2

[0044] The activated sludge is combined with the sorted domestic waste organic matter, and the ratio is 1:2 according to the dry basis weight; the solid-liquid ratio is 1:8, and the pH value is controlled at 4. The catalytic hydrolysis temperature is 250°C. The pressure is 1.0Mpa, and the reaction time is 10 hours. The catalyst is manganese series manganese oxide, and the amount of catalyst added is 5 / 1000 of the dry basis weight of organic materials (activated sludge + cow dung).

[0045] After hydrolyzing the solid ammonia, enter the solid-liquid separation device, use a plate and frame filter press, the operating pressure is 2.0Mpa, the filter press time is 2 hours, the temperature is 100°C, the water content of the filter cake is 49%, and the filter cake returns to hydrolysis after crushing The tank is re-hydrolyzed.

[0046] The filtrate passes through the coarse filter, first uses sand filter, and then selects a bag filter with automatic backwashing, and the filter spe...

Embodiment 3

[0051] The combination of activated sludge and crop orange stalks is 1:2.5 on a dry basis; the solid-liquid ratio is 1:8, and the pH value is controlled at 4. The catalytic hydrolysis temperature is 250°C. The pressure is 1.0Mpa, and the reaction time is 10 hours. The catalyst is manganese series manganese oxide, and the amount of catalyst added is one thousandth of the dry basis weight of organic materials (activated sludge + cow dung).

[0052] After hydrolyzing the solid ammonia, enter the solid-liquid separation device, use a plate and frame filter press, the operating pressure is 2.0Mpa, the filter press time is 2 hours, the temperature is 100°C, the water content of the filter cake is 49%, and the filter cake returns to hydrolysis after crushing The tank is re-hydrolyzed.

[0053] The filtrate passes through the coarse filter, firstly filters it with fiber cotton, and then selects a bag filter with automatic backwashing, and the filtering speed is 5m / hour. The filter ...

Embodiment 4

[0058] Activated sludge is combined with furfural slag xylitol slag at a ratio of 1:4 on a dry basis; the rest is the same as in Example 1. Add chemical nitrogen fertilizer, phosphoric acid and potassium fertilizer to adjust to N+P 2 o 5 +K 2 O total nutrients are greater than or equal to 10%, and water-soluble organic carbon (calculated as carbon) is greater than or equal to 35%. Finally, the finished product is measured and packaged as water-soluble organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com