Curable resin composition and cured product

A curable resin and composition technology, applied in the field of cured products, can solve the problems of excellent formability, yellowing, heat discoloration resistance, and low shrinkage, and achieve low thermal expansion, high transparency, and high heat discoloration resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

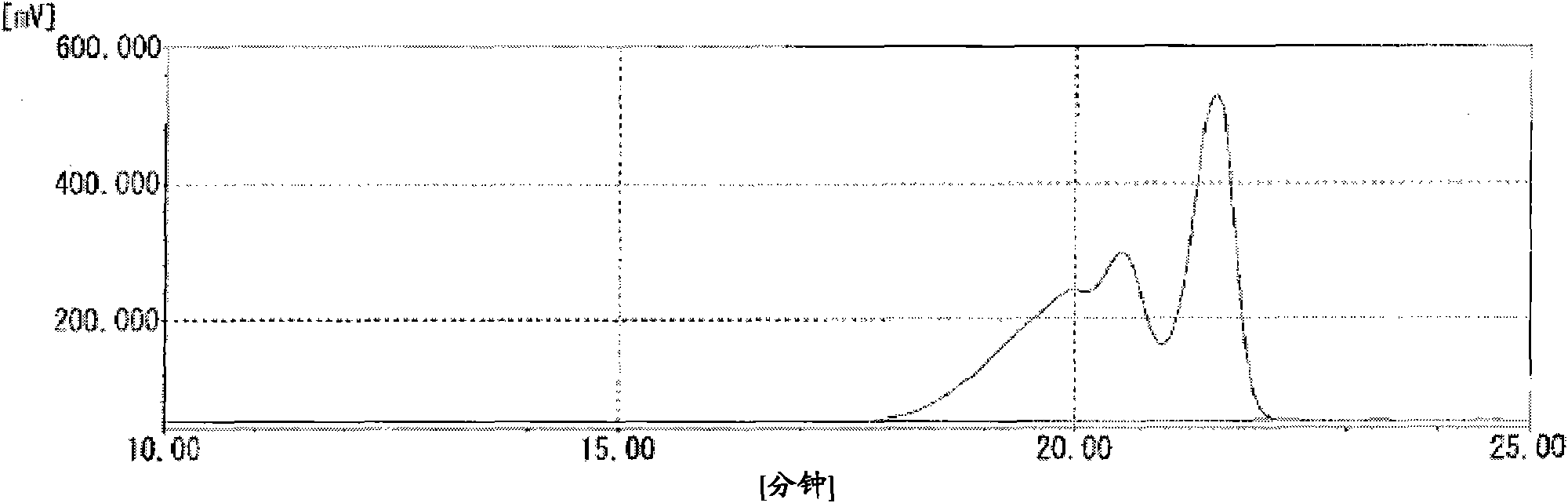

[0069] In a reaction vessel equipped with a stirrer, a dropping funnel, and a thermometer, 14.3 g of tetramethylammonium hydroxide pentahydrate (manufactured by Kanto Chemical Industry Co., Ltd.) was added as a basic catalyst, dissolved in 17.0 g of water, and then 189 mL of toluene and 2 - Propanol 95 mL. 46.8 g of vinyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.: KBM1003) was added to the dropping funnel, and vinyltrimethoxysilane was added dropwise at room temperature over 3 hours while stirring the reaction vessel. After completion of the dropwise addition, the mixture was stirred at room temperature for 2 hours. After the stirring was finished, the stirring was stopped and left to stand still for 1 day. Then, the reaction solution was neutralized with 82.9 g of 10% citric acid aqueous solution. The aqueous layer was extracted with toluene, and the organic layer was washed 3 times with distilled water. The organic layer was dried over anhydrous magnes...

Synthetic example 2

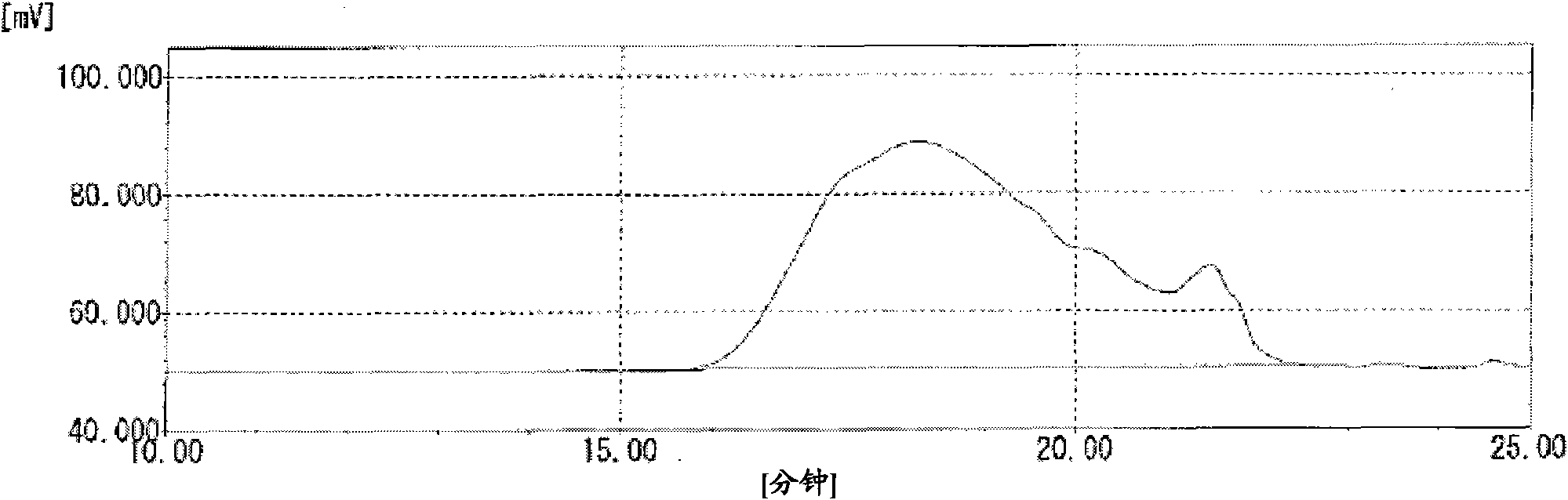

[0082] In a reaction container equipped with a stirrer, a dropping funnel, and a thermometer, 14.3 g of tetramethylammonium hydroxide pentahydrate was added as a basic catalyst, dissolved in 17 g of water, and then 189 mL of toluene and 95 mL of 2-propanol were added. Put 23.4 g of vinyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.: KBM1003) and 23.7 g of ethyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.: LS-890) into the dropping funnel, and stir the reaction vessel , A mixture of vinyltrimethoxysilane and ethyltrimethoxysilane was added dropwise at room temperature over 3 hours. After completion of the dropwise addition, the mixture was stirred at room temperature for 2 hours. After the stirring was finished, the stirring was stopped and left to stand still for 1 day. Next, the reaction vessel was provided with a Dean and Stark moisture meter and a condenser, 95 mL of toluene was added, and 2-propanol and methanol generated during hydrolys...

Synthetic example 3

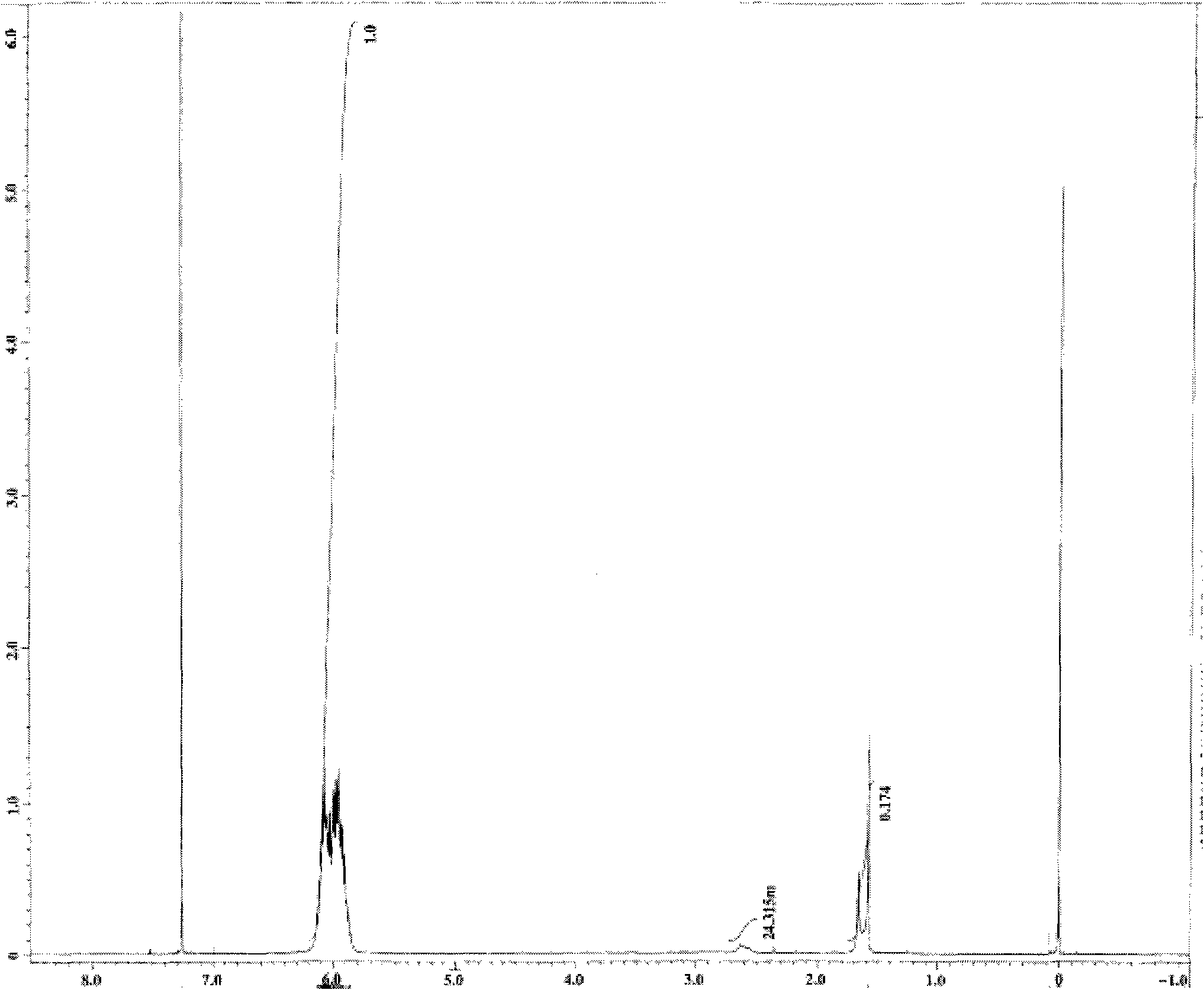

[0090] In a reaction container equipped with a stirrer, a dropping funnel, and a thermometer, 14.3 g of tetramethylammonium hydroxide pentahydrate was added as a basic catalyst, dissolved in 17 g of water, and then 189 mL of toluene and 95 mL of 2-propanol were added. 78.4 g of 3-methacryloxypropyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.: LS-3380) was added to the dropping funnel, and 3-methoxysilane was added dropwise at room temperature over 3 hours while stirring the reaction vessel. Methacryloxypropyltrimethoxysilane. After completion of the dropwise addition, the mixture was stirred at room temperature for 2 hours. After the stirring was finished, the stirring was stopped and left to stand still for 1 day. Next, the reaction vessel was equipped with a Dean and Stark moisture meter and a condenser, 95 mL of toluene was added, and 2-propanol and methanol generated during hydrolysis were removed with an oil bath at 90°C. Then, the temperature of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com