Anti-seepage heat insulating rice husk concrete and preparation method thereof

A concrete and rice husk technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as lining board cracking, joint dislocation, landslide collapse, etc., to eliminate pollution, light weight, porosity, etc. great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

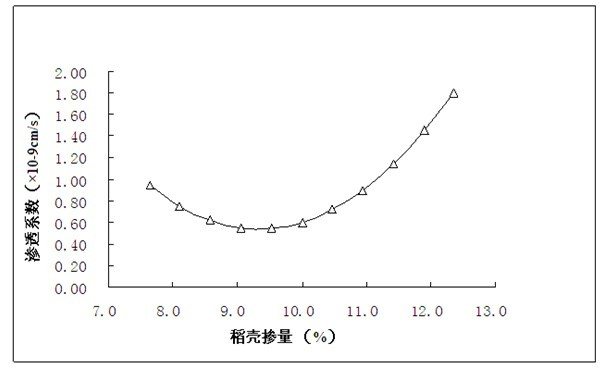

Image

Examples

Embodiment 1

[0028] 28.4% of cement; 19.3% of sand; 5% of fly ash; 30.9% of sand and pebbles (the particle size of sand and pebbles is 5-20mm); 12.8% of water; 2.6% of original rice husk; 0.8% of 108 glue; Water agent 0.2%; Among them, the water reducer is selected from the commercially available JSG powdered high-efficiency water reducer.

[0029] The preparation method comprises the following steps:

[0030] 1) Weigh rice husk or rice husk powder, fly ash, cement, sand, sand pebbles, 108 glue, and water reducing agent according to the mixing ratio, and control the water consumption based on the slump of 30~50mm;

[0031] 2) Dilute 108 glue with water, add water twice as much as 108 glue, pour it into the mixing basin and stir it manually for 10 minutes, and leave it for 20 minutes for use;

[0032] 3) Put rice husk or rice husk powder, fly ash, sand, stones, and cement into the mixer, add water, water reducing agent and the diluted 108 glue in step 2), pay attention to the amount of wat...

Embodiment 2

[0036] Take 28.1% cement; 16.8% sand; 34.9% sand and pebbles (the particle size of sand and pebbles is 5-20mm); 2.4% fly ash; 13.8% water; 2.9% original rice husk; Water agent 0.2%, of which the water reducer is commercially available GJ-1 powdered high-efficiency water reducer.

[0037] Mix according to the production method of Example 1 (the slump is controlled at 10-30mm), put it on a vibrating table and vibrate for 30s before forming, plaster the surface before the initial setting of the concrete, remove the mold after 24 hours, and send it to the curing room for standard curing .

[0038] Product indicators reached: compressive strength 16Mpa, apparent density 1723kg / m 3 , permeability coefficient 0.466×10 -8 cm / s, compressive strength 14.5Mpa after freeze-thaw test, thermal conductivity 0.2452W (mK) -1 .

Embodiment 3

[0040] Take 24% cement by weight ratio; 23.2% sand; 37.4% sand pebbles (the particle size of sand pebbles is 5-31.5mm); 9.9% water; screened); fly ash 4.1%; 108 glue 0.3%; water reducing agent 0.2%, among which the water reducing agent is selected from the commercially available JSG powdered high-efficiency water reducing agent.

[0041] Mix according to the production method of Example 1 (the slump is controlled at 30-50mm), put it on a vibrating table and vibrate for 30s before forming, plaster the surface before the initial setting of the concrete, remove the mold after 24 hours, and send it to the curing room for standard curing .

[0042] Product index reached: apparent density 2250kg / m 3, compressive strength 23.6Mpa, permeability coefficient 3.681×10 -9 cm / s, after 50 freeze-thaw cycle experiments, the mass loss is 0.5%, and the relative dynamic elastic modulus of concrete is 94.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com