AlGaN/GaN high-electron-mobility transistor and manufacturing method thereof

A technology with high electron mobility and fabrication method, which is applied in the structural fields of high-speed devices and high-frequency devices, semiconductor devices, and short-channel AlGaN/GaN high electron mobility transistors, and can solve problems affecting Schottky gate characteristics, etc. Achieve the effect of improving radiation resistance, increasing electrical conductivity, and reducing the length of the channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

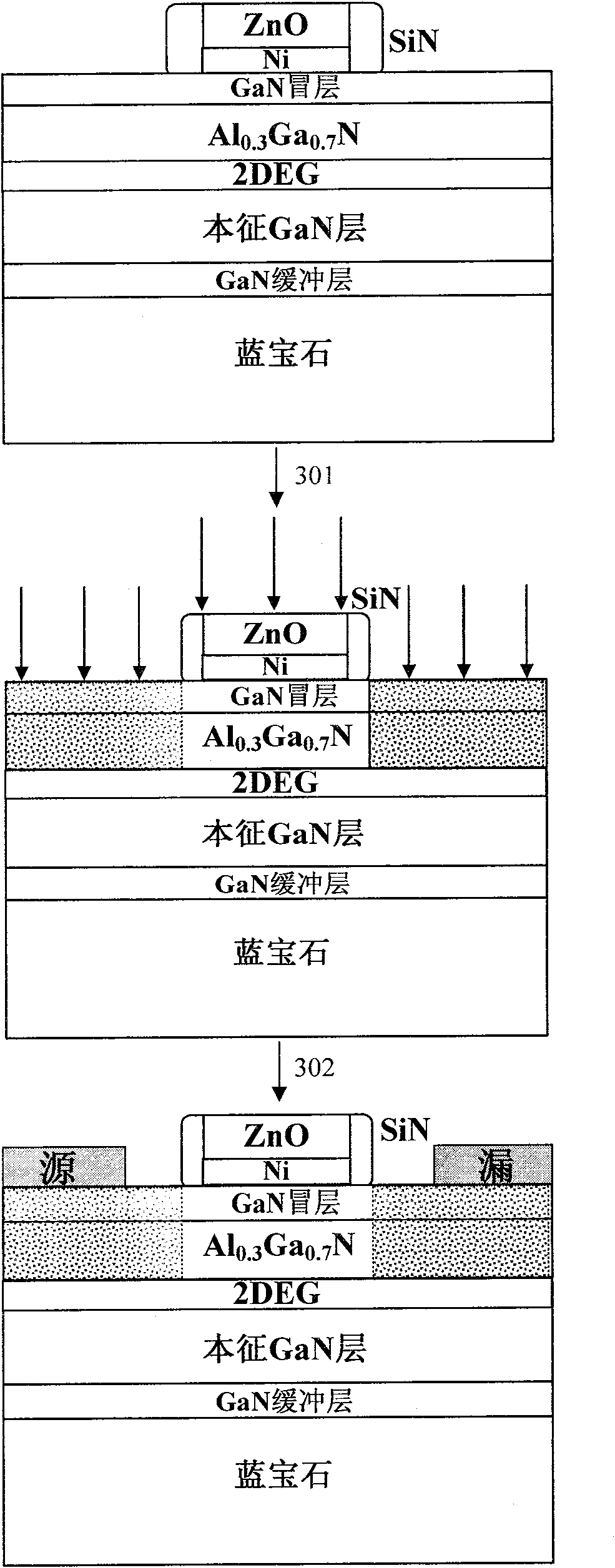

[0030] Embodiment 1, the making of device of the present invention, comprises the following steps:

[0031] Step 1. Epitaxial material growth.

[0032] refer to figure 1 and figure 2 , the specific implementation of this step is as follows:

[0033] (101) On the sapphire substrate substrate, utilize the MOCVD process to grow a GaN buffer layer;

[0034] (102) growing an intrinsic GaN layer on the GaN buffer layer;

[0035] (103) On the intrinsic GaN layer, a 20nm thick Al 0.3 Ga 0.7 N layer;

[0036] (104) in Al 0.3 Ga 0.7 On the N layer, a 2nm thick GaN capping layer is grown.

[0037] Step 2. Gate electrode fabrication.

[0038] refer to figure 1 and image 3 , the specific implementation of this step is as follows:

[0039] (201) Photoetching a gate electrode pattern on the surface of the grown GaN material. In order to peel off the metal better, firstly, the adhesive is shaken on the sample at a speed of 8000 rpm for 30 seconds, and baked in a high-temperature...

Embodiment 2

[0054] Embodiment 2, the making of device of the present invention, comprises the following steps:

[0055] Step 1. Epitaxial material growth.

[0056] refer to figure 1 and figure 2 , the specific implementation of this step is as follows:

[0057] (101) On the sapphire substrate substrate, utilize the MOCVD process to grow a GaN buffer layer;

[0058] (102) growing an intrinsic GaN layer on the GaN buffer layer;

[0059] (103) On the intrinsic GaN layer, a 20nm thick Al 0.3 Ga 0.7 N layer;

[0060] (104) in Al 0.3 Ga 0.7 On the N layer, a 2nm thick GaN capping layer is grown.

[0061] Step 2. Make the gate electrode.

[0062] refer to figure 1 and image 3 , the specific implementation of this step is as follows:

[0063] (201) Photoetching a gate electrode pattern on the surface of the grown GaN material. In order to peel off the metal better, firstly, the adhesive is shaken on the sample at a speed of 8000 rpm for 30 seconds, and baked in a high-temperature ...

Embodiment 3

[0078] Embodiment 3, the making of device of the present invention, comprises the following steps:

[0079] Step 1. Epitaxial material growth.

[0080] refer to figure 1 and figure 2 , the specific implementation of this step is as follows:

[0081] (101) On the sapphire substrate substrate, utilize the MOCVD process to grow a GaN buffer layer;

[0082] (102) growing an intrinsic GaN layer on the GaN buffer layer;

[0083] (103) On the intrinsic GaN layer, a 20nm thick Al 0.3 Ga 0.7 N layer;

[0084] (104) in Al 0.3 Ga 0.7 On the N layer, a 2nm thick GaN capping layer is grown.

[0085] Step 2. Gate electrode fabrication.

[0086] refer to figure 1 and image 3 , the specific implementation of this step is as follows:

[0087] (201) Photoetching a gate electrode pattern on the surface of the grown GaN material. In order to peel off the metal better, firstly, the adhesive is shaken on the sample at a speed of 8000 rpm for 30 seconds, and baked in a high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com