Integral load-bearing, thermal-insulation heat-preservation wall body structure

A heat insulation and wall structure technology, applied to walls, building components, building structures, etc., can solve the problems that it is difficult to meet the requirements of environmental protection and energy saving, there are many disadvantages of heat preservation, and it cannot meet the requirements of low-carbon society and modernization construction, etc. The effect of increasing strength and reducing engineering cost and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

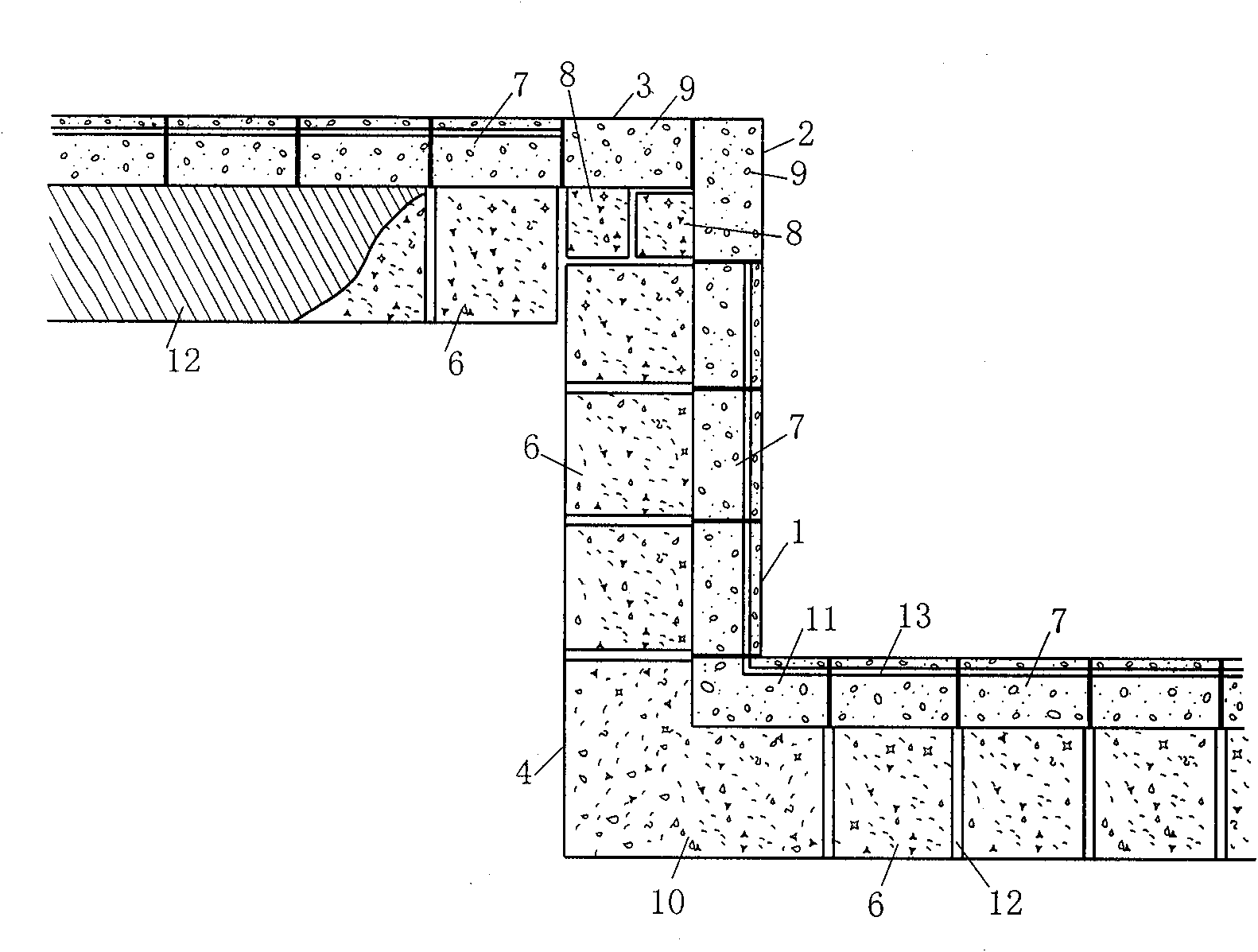

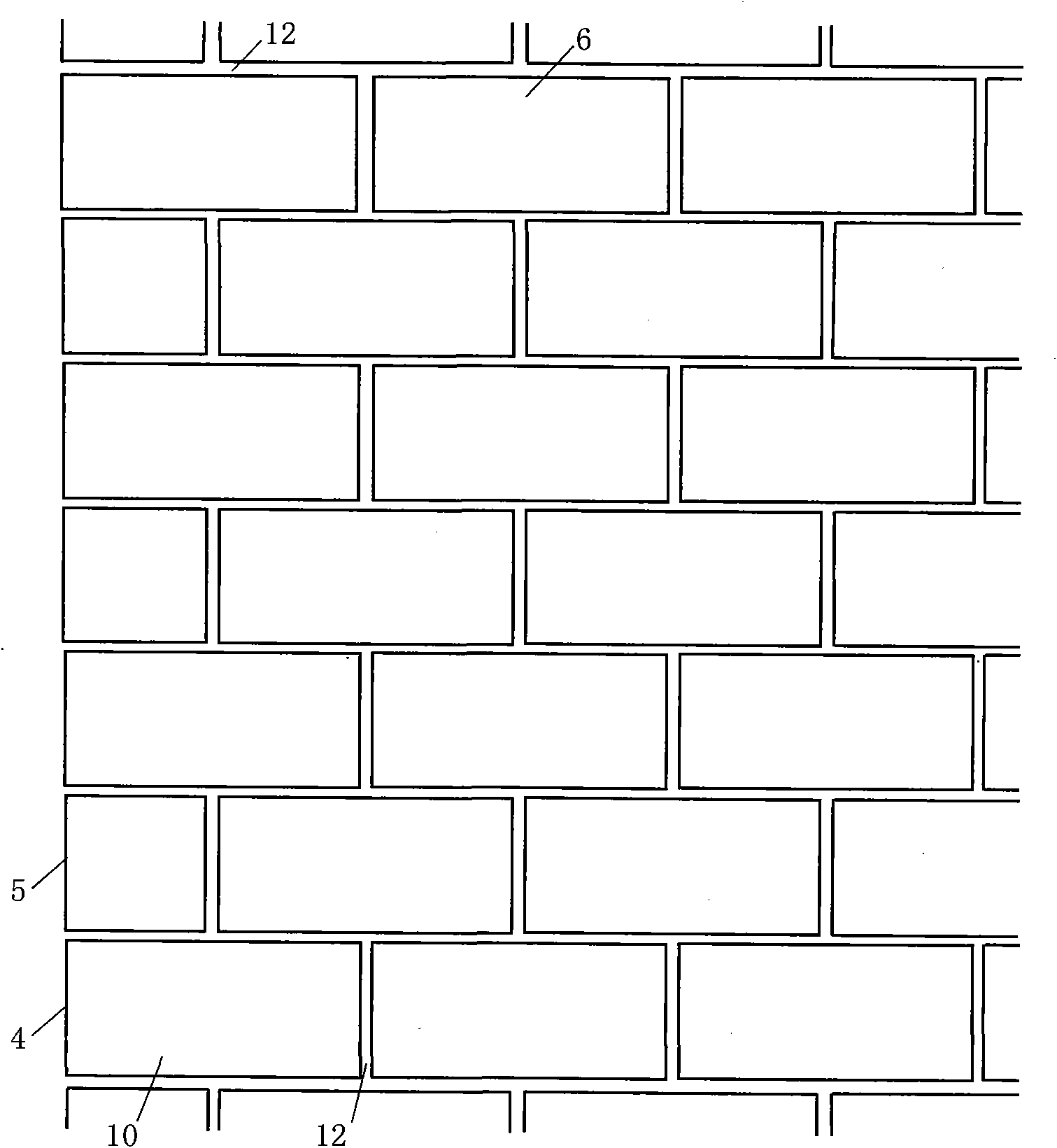

[0042] Such as Figure 1 to Figure 3As shown, a load-bearing, heat-insulating and heat-preserving integrated wall structure of the present invention includes a straight brick 1, a left corner brick 2, a right corner brick 3, a left corner brick 4, and a right corner brick 5. The bricks are composed of high-density and low-density cuboids. A high-density cuboid 6 and a low-density cuboid 7 are arranged on the straight brick 1, a high-density cuboid 8 and a low-density cuboid 9 are arranged on the left corner brick 2 and the right corner brick 3, and a left corner brick 4 and High-density right-angled brick body 10 and low-density cuboid 11 are all arranged on the right inner corner brick 5, high-density cuboid 6 at straight brick 1, high-density cuboid 8 at left male corner brick 2 and right male corner brick 3, left There are no steps 12 on the high-density right-angled brick body 10 of the inner corner 4 and the right inner corner 5 and on the adjacent side surfaces as a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com