Self-positioning mounting steel wood energy dissipation combined joint

A combined node and self-positioning technology, which is applied to building components, building types, earthquake resistance, etc., can solve problems such as various tooth plate connection configurations, wood damage of bolted connection nodes, yield failure of nails or screws, etc., to improve energy consumption capacity , The energy consumption mechanism is clear, and the effect of improving the shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

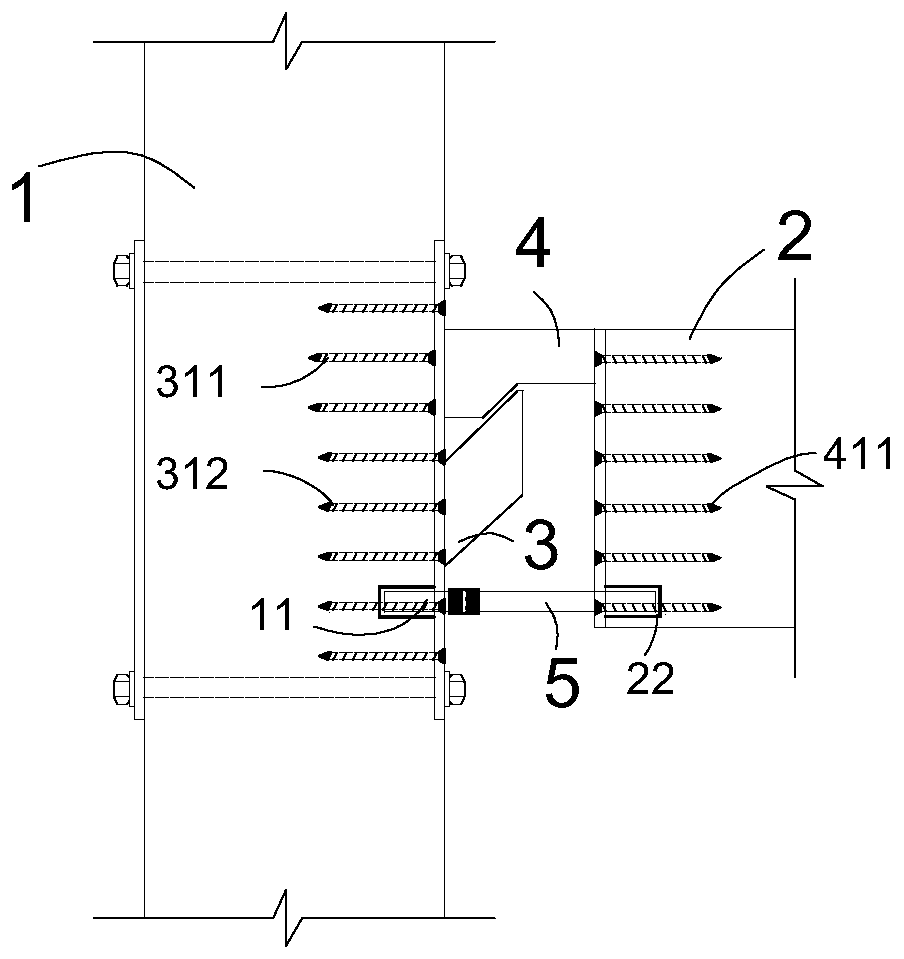

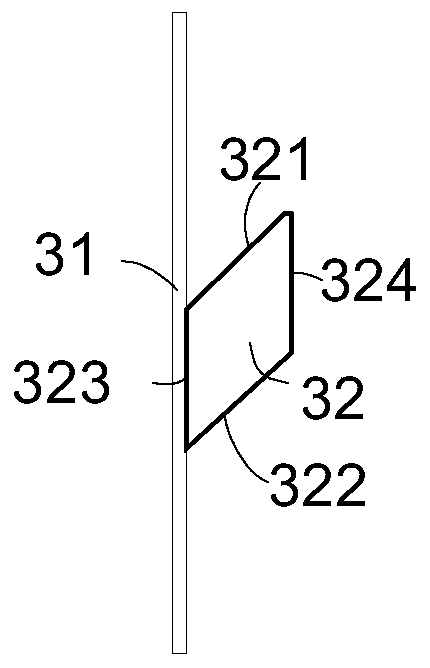

[0029] Such as Figure 6-8 The difference between this embodiment and Embodiment 1 is that the steel wedge hanging 4 bottom can be welded with a stiffening plate 43, the right side of the stiffening plate 43 is consolidated with the end steel plate 41 of the steel wedge hanging 4, and the upper side is connected with the steel wedge hanging 4 The oblique wedge surface 424 and the transitional horizontal bottom surface 425 are consolidated, and the corresponding groove 33 is opened on the steel support 3 corresponding to the stiffening plate 43 .

[0030] Such as Figure 9 , when the vertical column 1 and the horizontal beam 2 are in place, after the wooden beam is put in, driven by the load-bearing of the wooden beam, the inclined wedge surface 424 of the steel wedge hanger 4 and the inner inclined support surface of the steel inclined support 3 The relative sliding of 321 can make the vertical column 1 and the horizontal beam 2 self-positioning and installed.

[0031] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com