Method for producing 1,3-propylene glycol by micro aerobic-anaerobic continuous flowing glycerol-adding multi-tank series fermentation

A technology of propylene glycol and glycerin, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of waste of raw materials, short non-production time, high production cost, etc., to reduce production costs, increase cell density, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

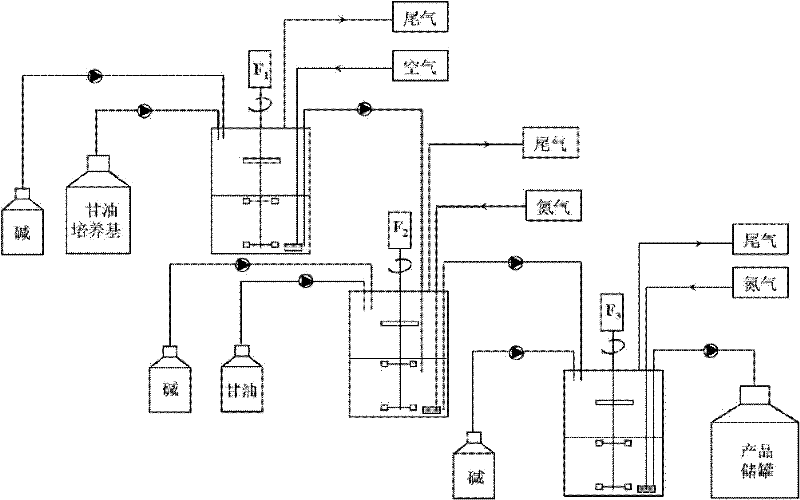

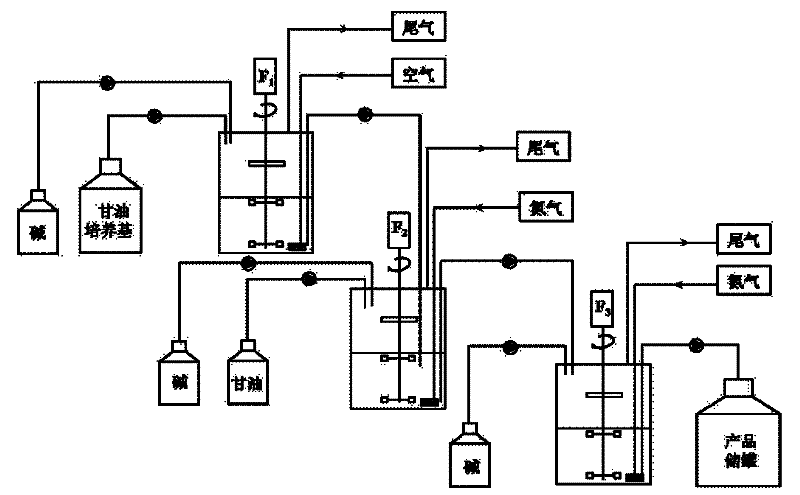

Image

Examples

example 1

[0031] Continuous fermentation is carried out in a fully automatic fermenter, the working volume is 5L, the actual liquid volume is 1.5L, the inoculum size is 10%, the speed control is 150r / m, the ventilation rate of air or nitrogen is 0.04vvm, and 5mol / L NaOH is used. The pH of the solution was adjusted to 7.0, and the temperature was controlled at 37°C. The initial glycerol concentrations in fermentors 1, 2 and 3 were 40, 20 and 20 g / L, respectively.

[0032] Fermentation tank 1: Introduce air to maintain a micro-aerobic environment, first carry out intermittent culture, and wait for the bacteria OD 650 When it reaches 3.0, take another 0.2h -1 The dilution rate is fed into the fermentation medium for chemostat culture. The glycerol concentration in the medium is 40g / L. When the steady state is reached, the OD of the bacteria is 650 The value was 5.1, the residual glycerol concentration was 0.9 g / L, the concentration and molar conversion of 1,3-PD were 15.2 g / L and 0.47 mo...

example 2

[0036] Fermentation process is the same as example 1, and the concentration of glycerol in the medium entering fermentor 1 is 70g / L, and the dilution rate is 0.1h -1 , the control residual glycerol concentration in the fermenter 2 is 18.9g / L.

[0037] Experimental results show that the final concentration of 1,3-PD can reach 39.5g / L, the production intensity is 4.0g / L·h, and the concentration of residual glycerol is only 1.4g / L.

example 3

[0039] Fermentation process is the same as example 1, and the concentration of glycerol in the medium of fermentor 1 is 90g / L, and dilution rate is 0.1h -1 , the control residual glycerol concentration in the fermenter 2 is 18.4g / L.

[0040] Experimental results show that the final concentration of 1,3-PD can reach 41.1g / L, the production intensity is 4.1g / L·h, and the concentration of residual glycerol is 10.1g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com