Chain extension method of engineering resin and reclaimed material thereof

A technology of engineering resin and recycled materials, which is applied in the field of polymer materials, can solve the problems of black spots or gel points of materials, the need for master batching, and high cost of use, and achieve the effects of high use efficiency, wide range of uses, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

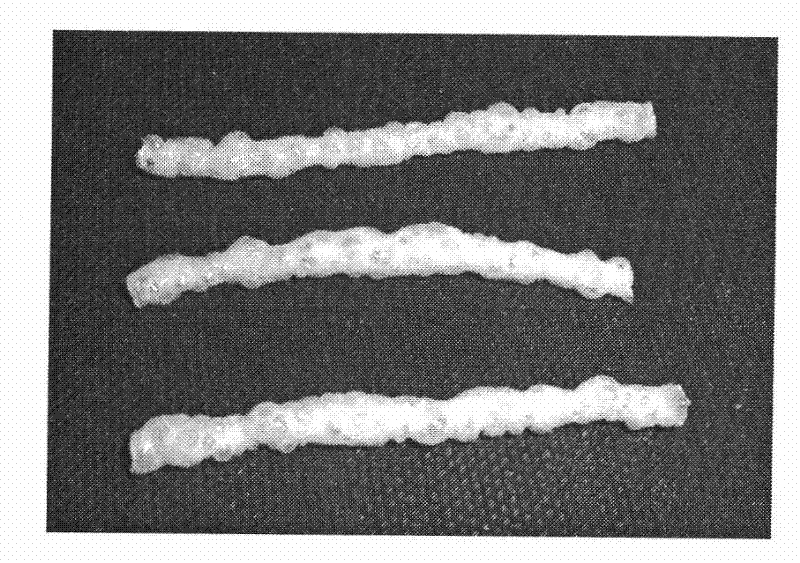

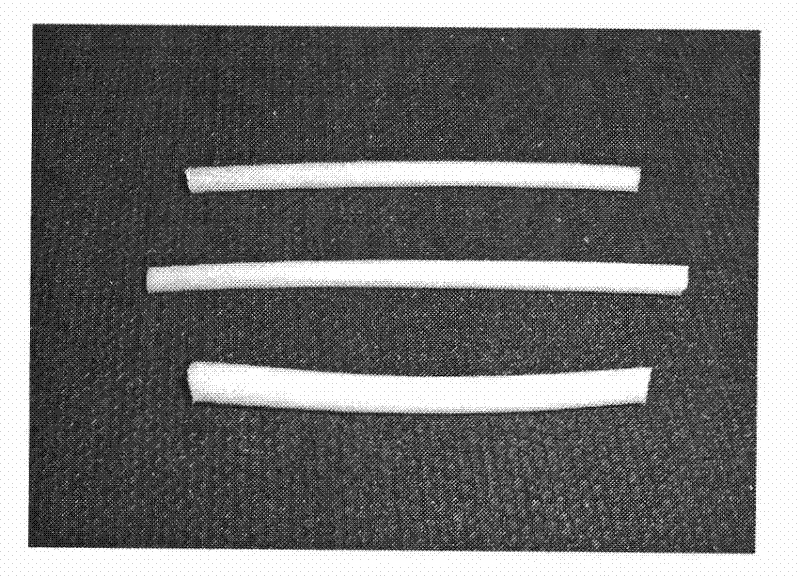

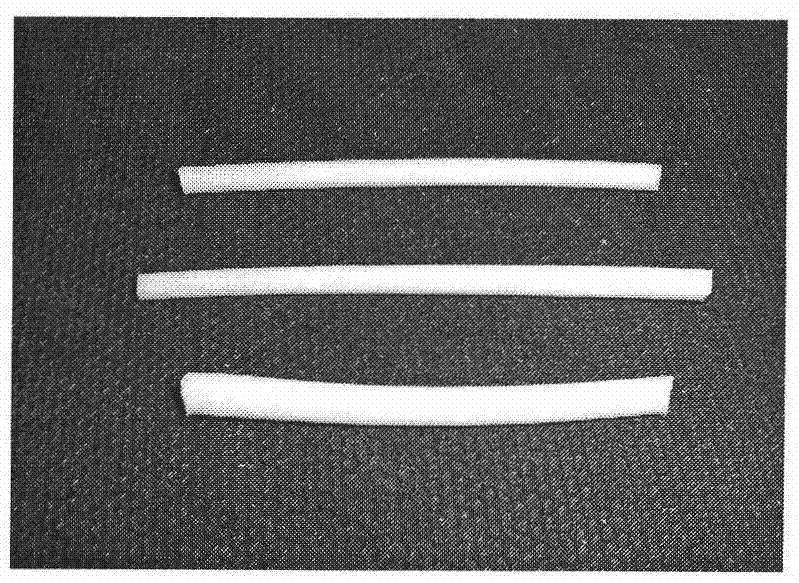

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0048] Chain extension method:

[0049] Weigh 100 parts by weight of engineering resin reclaimed material as a benchmark.

[0050] Add the following components:

[0051] 1 to 10 parts by weight of the terpolymer of the present invention as a chain extender;

[0052] 0.1-0.5 parts by weight of antioxidant 1010;

[0053] 0.1-0.5 parts by weight of white oil or silicone oil;

[0054] Then in the high mixer, use the speed of 2000rpm, control the temperature below 90°C, mix for about 1-5 minutes, use a twin-screw extruder with an aspect ratio greater than 34, and granulate at a temperature of 220-260°C.

[0055] Its physical and mechanical properties are implemented according to the following standards.

[0056] Tensile properties: ASTM D638, bending properties: ASTM D 790, Izod impact properties: ASTM D256, melt index: ASTM D 1238 (260°C×5kg)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com