Production method for polyvinyl chloride powder for preparing baffle plate of lead acid storage battery

A technology of polyvinyl chloride powder and lead-acid battery, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of insufficient strength of the separator, poor microporous structure, damage to equipment, etc., and achieve good microporous structure. , Optimize the polymerization process, the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 260kg of desalted water into the polymerization kettle, start stirring, mix 160kg of vinyl chloride, 1kg of sodium lauryl sulfate, 1.5kg of sodium stearate, initial amount of 0.016kg of potassium persulfate, 0.32kg of sodium bisulfite, 0.003kg of Put copper chloride and 0.06kg sodium hydroxide into the kettle, stir at a speed of 40 rpm, polymerize at 50°C, add the remaining amount of potassium persulfate aqueous solution continuously according to the reaction rate, polymerize for 10-12 hours, when the pressure in the kettle drops When the temperature reaches 0.4 MPa, add 0.4 kg of sodium stearate, stir for 10 minutes, start to recover unreacted vinyl chloride in the kettle, and spray-dry the obtained latex to obtain a finished powdery vinyl chloride polymer. The finished product meets the requirements of the Q / GH.JS0218-91 standard. The test results are shown in Table 2.

Embodiment 2

[0032] Add 260kg of desalted water into the polymerization kettle, start stirring, and mix 160kg of vinyl chloride, 0.8kg of sodium laurate, 0.4kg of myristic acid, 1.2kg of sodium stearate, initial quantities of 0.016kg of potassium persulfate, and 0.32kg of sodium bisulfite , 0.003kg of copper chloride, 0.06kg of sodium hydroxide are put into the kettle, the stirring speed is 40 rev / min, polymerized at 50°C, and the remaining amount of potassium persulfate aqueous solution is continuously added according to the reaction rate, polymerized for 10-12 hours, when the kettle When the internal pressure drops to 0.4 MPa, add 0.4 kg of sodium laurate, stir for 10 minutes, start to recover unreacted vinyl chloride in the kettle, and spray-dry the obtained latex to obtain a finished powdery vinyl chloride polymer. The resulting finished product meets the requirements of the Q / GH.JS0218-91 standard, and the test results are shown in Table 2.

Embodiment 3

[0034] Add 260kg of desalted water in the polymerization kettle, start stirring and mix 160kg vinyl chloride, 0.8kg sodium dodecylbenzenesulfonate, 1.6kg sodium stearate, initial amount 0.016kg Potassium persulfate, 0.32kg of sodium bisulfite, 0.003kg of copper chloride, and 0.06kg of sodium hydroxide were put into the kettle. The stirring speed is 40 revolutions / min, polymerize at 50°C, continuously add the remaining amount of potassium persulfate aqueous solution according to the reaction rate, polymerize for 10-12 hours, when the pressure in the kettle drops to 0.4MPa, add 0.4kg of sodium stearate, After stirring for 10 minutes, unreacted vinyl chloride was recovered in the kettle, and the obtained latex was spray-dried to obtain a finished powdery vinyl chloride polymer. The resulting finished product meets the requirements of the Q / GH.JS0218-91 standard, and the test results are shown in Table 2.

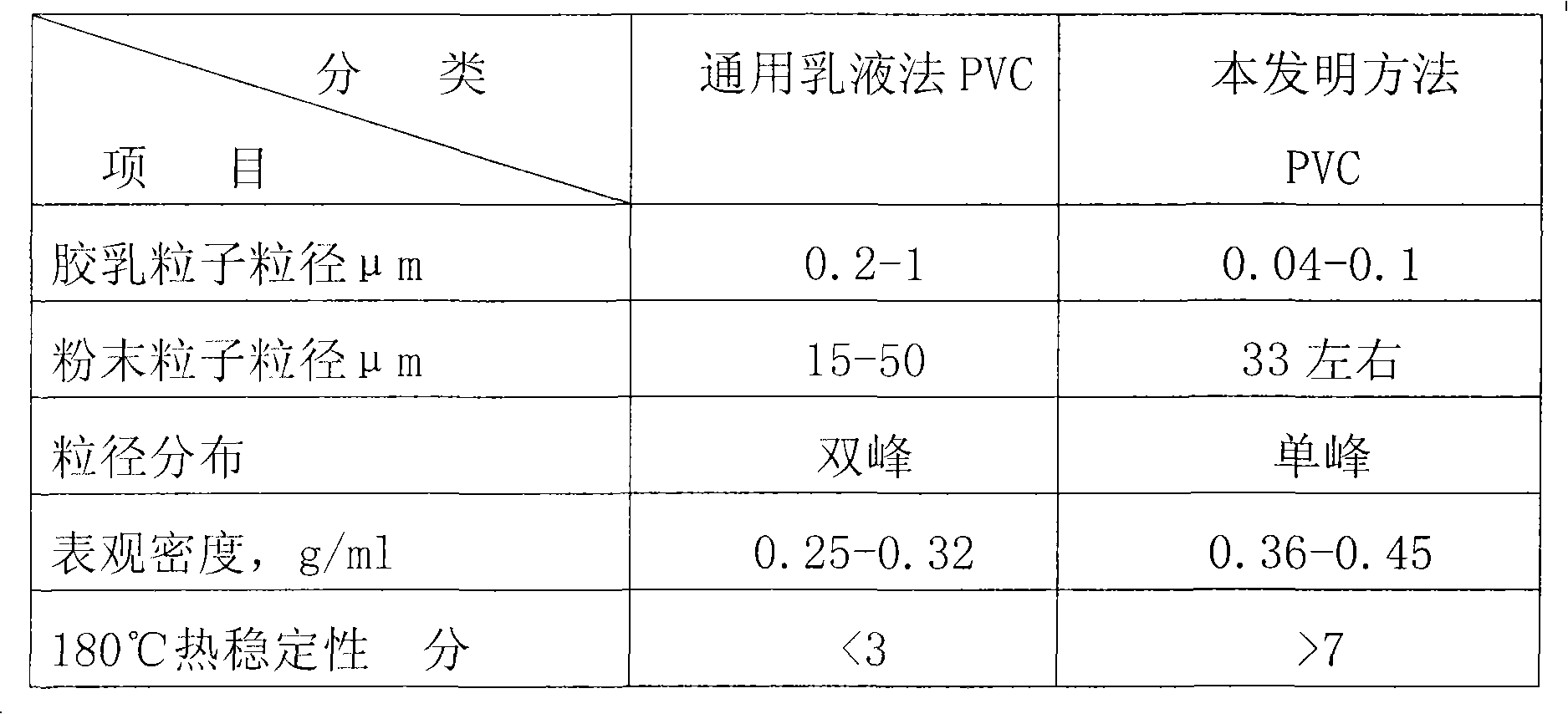

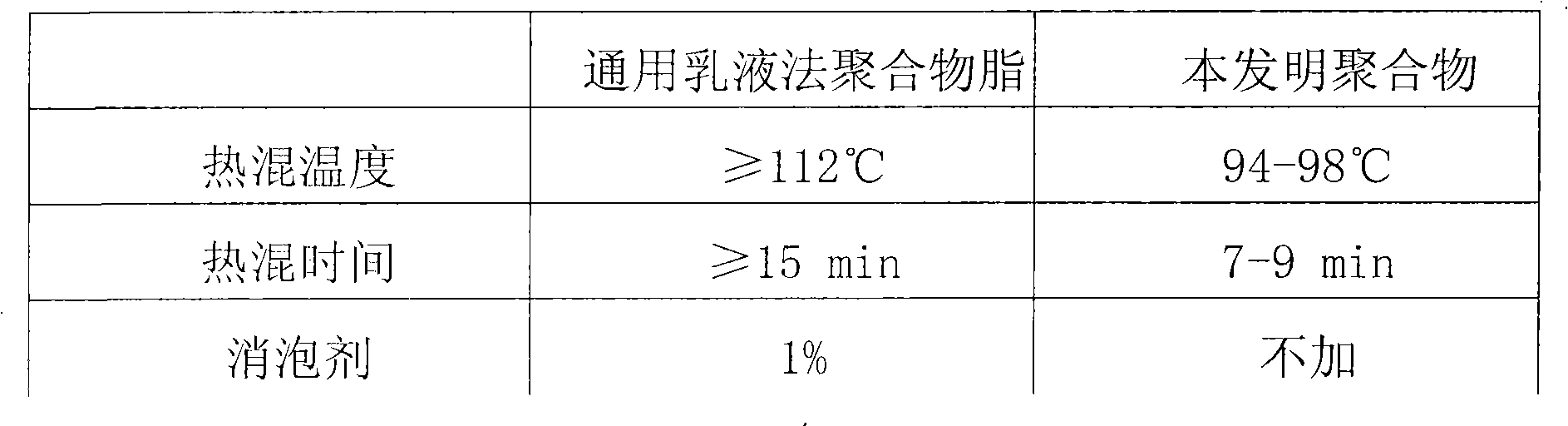

[0035] Table 2 The performance test results of vinyl chloride powder poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com