High-specific-energy/high-specific-power type super battery

A super battery, high specific power technology, used in secondary batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problems of unsatisfactory life and safety, long cycle life, small self-discharge, etc. power, increased reliability, good cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

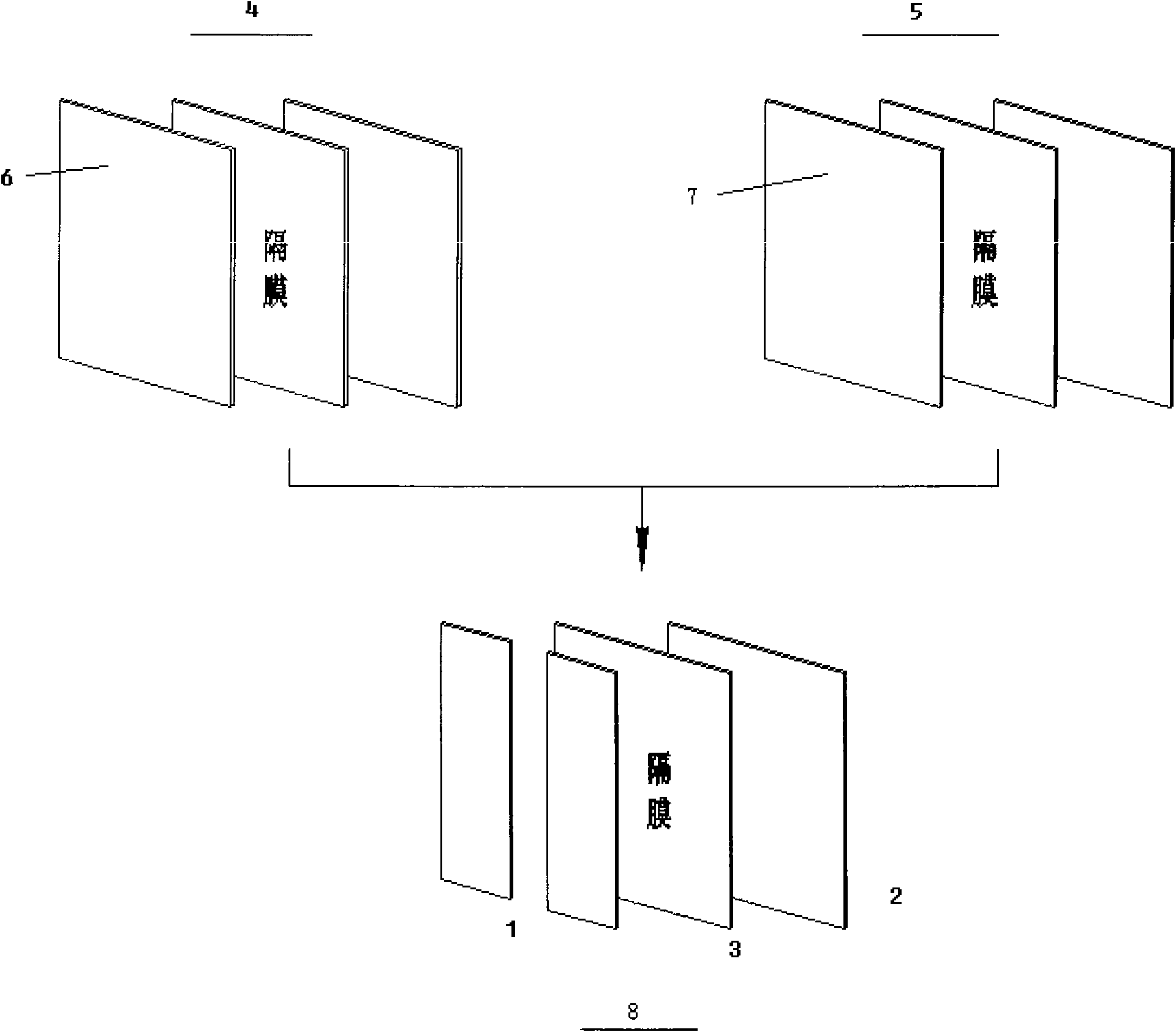

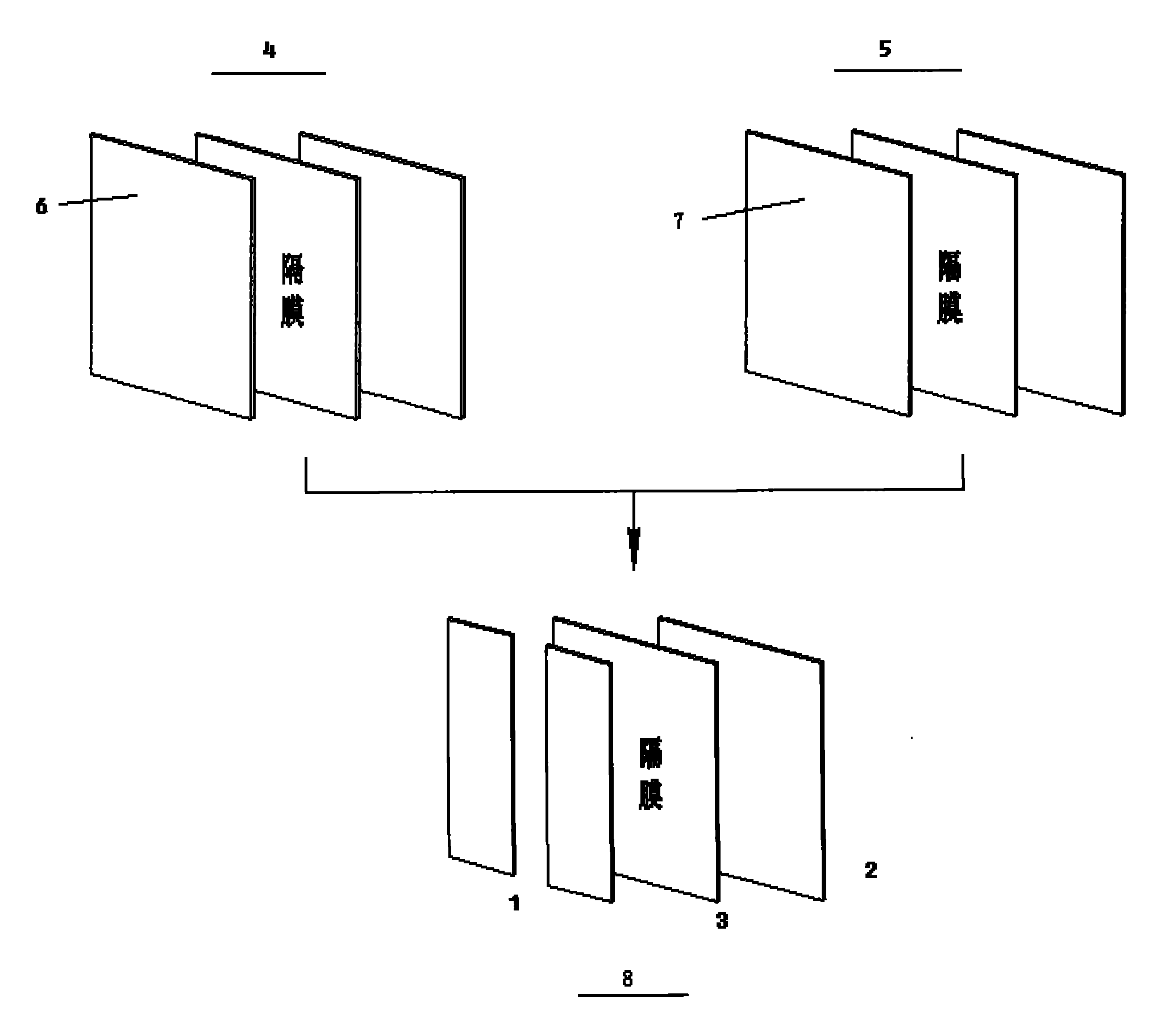

Image

Examples

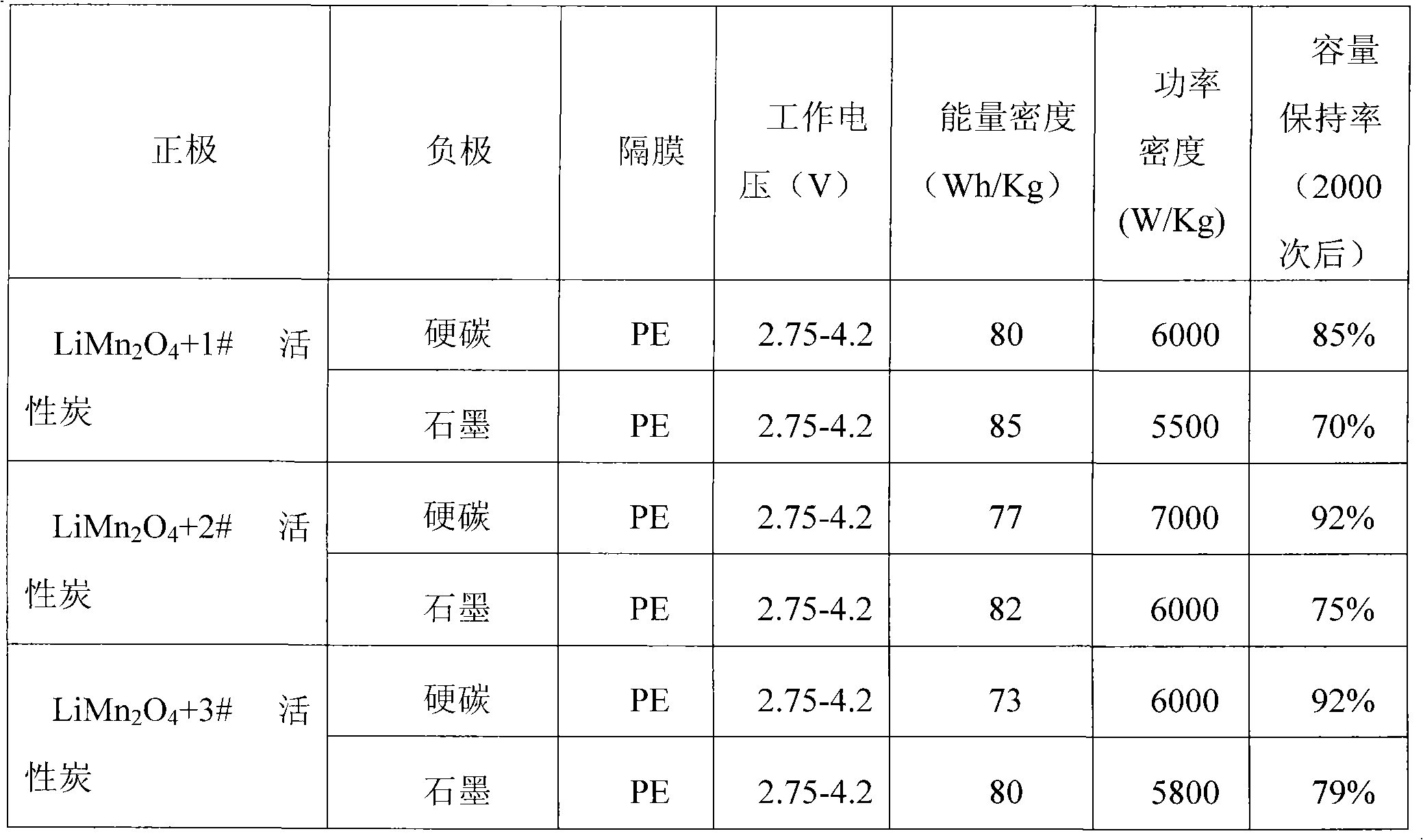

Embodiment 1

[0044] The preparation steps of the positive electrode sheet of lithium ion intercalation compound: the LiMn that total amount is 200g 2 o 4 , conductive carbon black, and PVDF are mixed in a mass ratio of 85:8:7, adjusted to a slurry with NMP, and then coated on a 20 μm aluminum foil (the coating weight gain is: 20mg / cm 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37*59mm 2 ), 24h vacuum drying (120~130°C) to make a positive electrode sheet; the preparation steps of the activated carbon positive electrode sheet are as follows: a total amount of 200g of activated carbon, conductive carbon black, PVDF is mixed in a mass ratio of 90:5:5, and NMP Make a slurry, and then coat it on a 16μm aluminum foil (coating gain: 15mg / cm 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37*59mm 2 ), 24h vacuum drying (120~130°C) to make a positive electrode sheet; the production of negative electrode sheet: mix a total of 400g of hard carbon and PVDF at a mass ratio o...

Embodiment 2

[0046] The preparation steps of the positive electrode sheet of lithium ion intercalation compound: the LiMn that total amount is 200g 2 o 4 , conductive carbon black, and PVDF are mixed in a mass ratio of 85:8:7, adjusted to a slurry with NMP, and then coated on a 20 μm aluminum foil (the coating weight gain is: 20mg / cm 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37*59mm 2 ), 24h vacuum drying (120~130°C) to make a positive electrode sheet; the preparation steps of the activated carbon positive electrode sheet are as follows: a total amount of 200g of activated carbon, conductive carbon black, PVDF is mixed in a mass ratio of 90:5:5, and NMP Make a slurry, and then coat it on a 20μm aluminum foil (coating gain: 15mg / cm 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37*59mm 2 ), 24h vacuum drying (120~130°C) to make a positive electrode sheet; the production of negative electrode sheet: mix a total of 400g of graphite and PVDF at a mass ratio of 9...

Embodiment 3

[0048] The preparation steps of the positive electrode sheet of lithium ion intercalation compound: the LiMn that total amount is 200g 2 o 4, conductive carbon black, and PVDF are mixed in a mass ratio of 85:8:7, adjusted to a slurry with NMP, and then coated on a 20 μm aluminum foil (the coating weight gain is: 20mg / cm 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37*59mm 2 ), 24h vacuum drying (120~130°C) to make a positive electrode sheet; the preparation steps of the activated carbon positive electrode sheet are as follows: a total amount of 200g of activated carbon, conductive carbon black, PVDF is mixed in a mass ratio of 90:5:5, and NMP Make a slurry, and then coat it on a 20μm aluminum foil (coating gain: 20mg / cm 2 ), dried (110-120°C), rolled, and cut into pieces (size: 37*59mm 2 ), 24h vacuum drying (120~130°C) to make a positive electrode sheet; the production of negative electrode sheet: mix a total of 400g of hard carbon and PVDF at a mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com