Encapsulating method of large power reactor

A packaging method and reactor technology, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve problems such as uneven strength, poor impact resistance, cracking, etc., and achieve low internal stress, good fluidity, and energy saving The effect of manufacturing hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment:

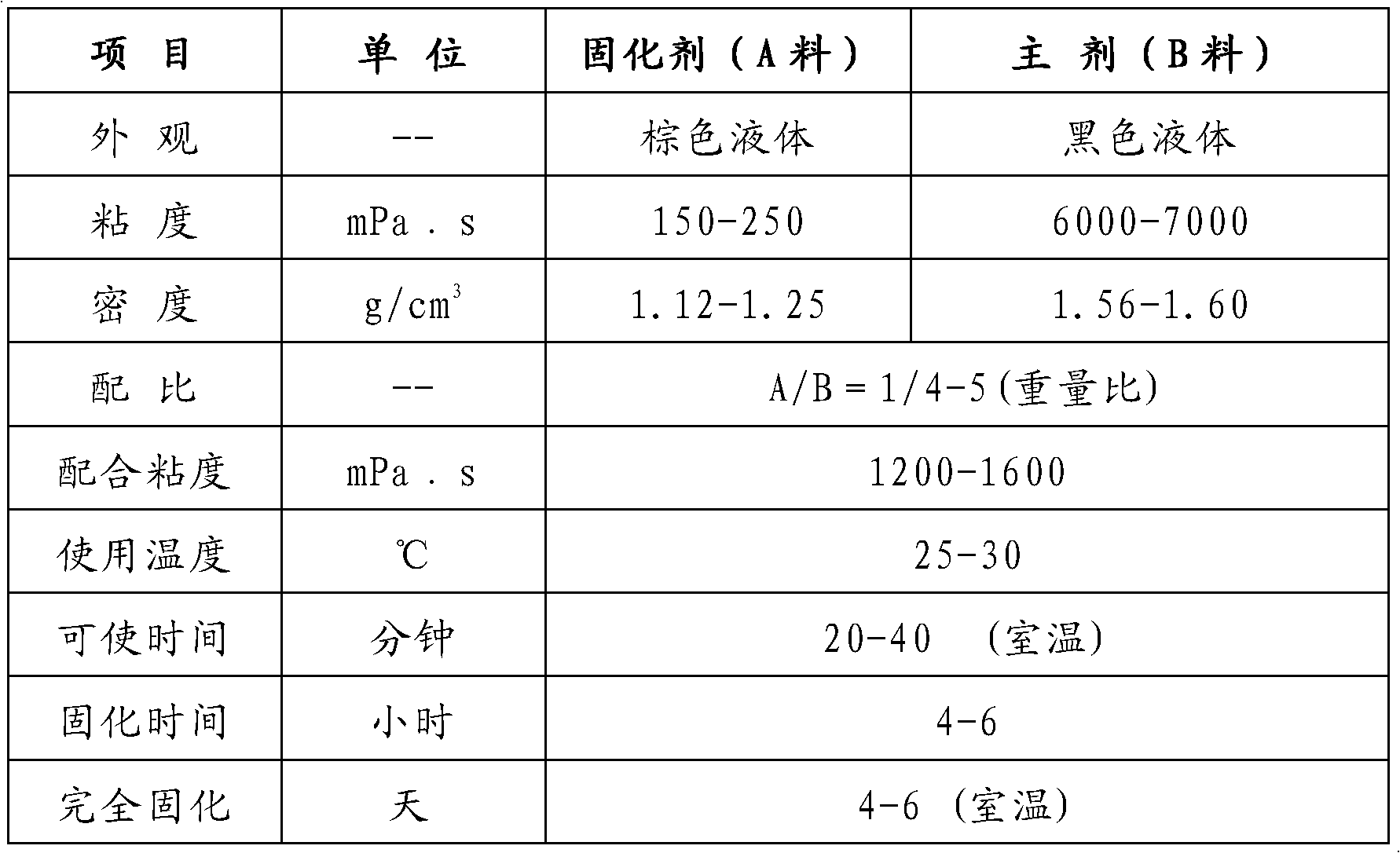

[0017] The polyurethane general characteristic that present embodiment adopts is as follows:

[0018]

[0019] The curing characteristics are as follows:

[0020] project

[0021] The packaging method steps of the present invention are as follows:

[0022] A. Pretreatment: preheat polyurethane material A and material B at 20-30°C, mix them according to the weight ratio of 1:4, and perform defoaming treatment for 150-210 seconds.

[0023] B. Pouring and encapsulation: Pouring the above-mentioned pretreated polyurethane on the coil and the mold, the temperature at the casting site is 20-26°C, the humidity is ≤65%, and it solidifies at room temperature for 6-10 hours after completion, the complete curing time of polyurethane and the product The hardness will vary due to the difference in ambient temperature. The curing time at room temperature is about 120 hours, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com