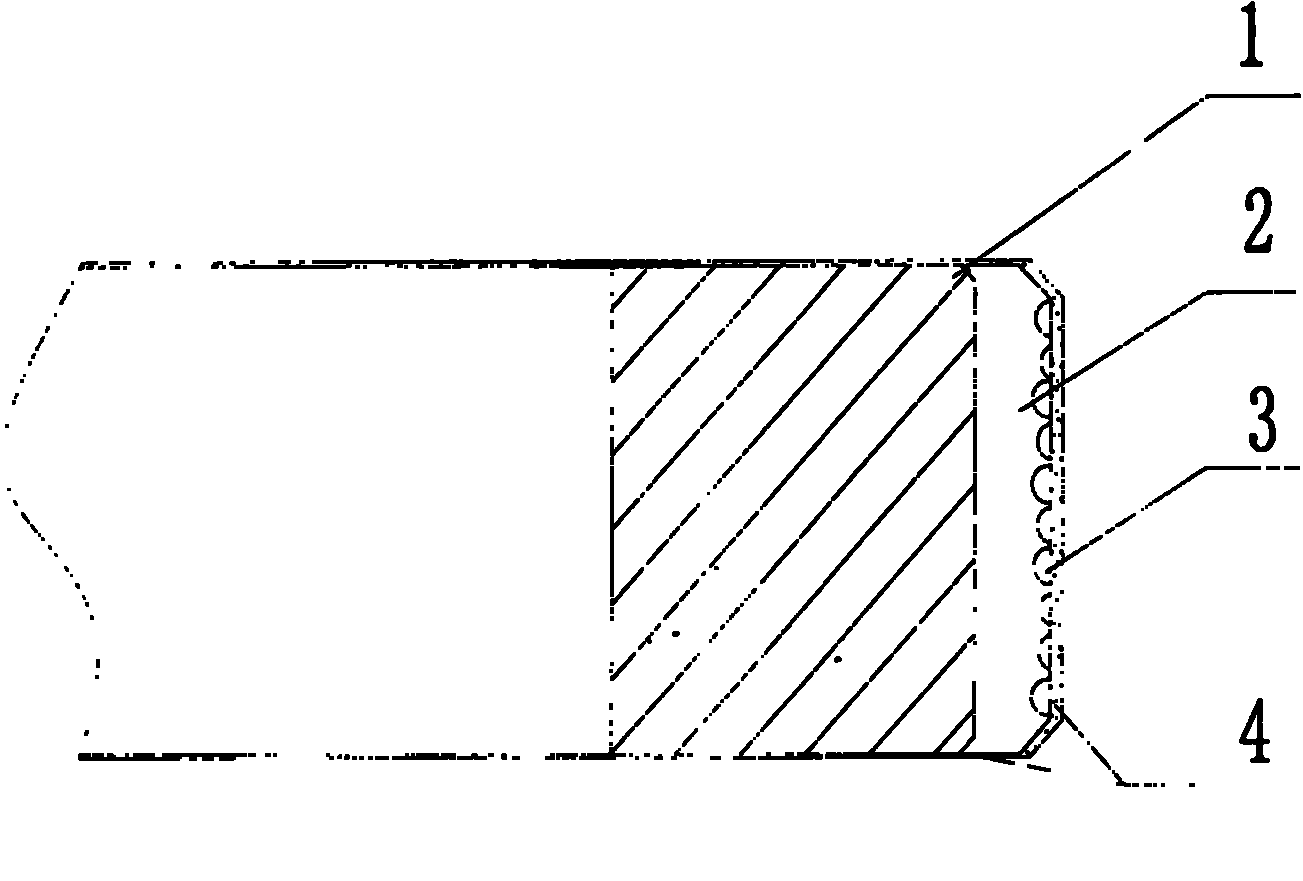

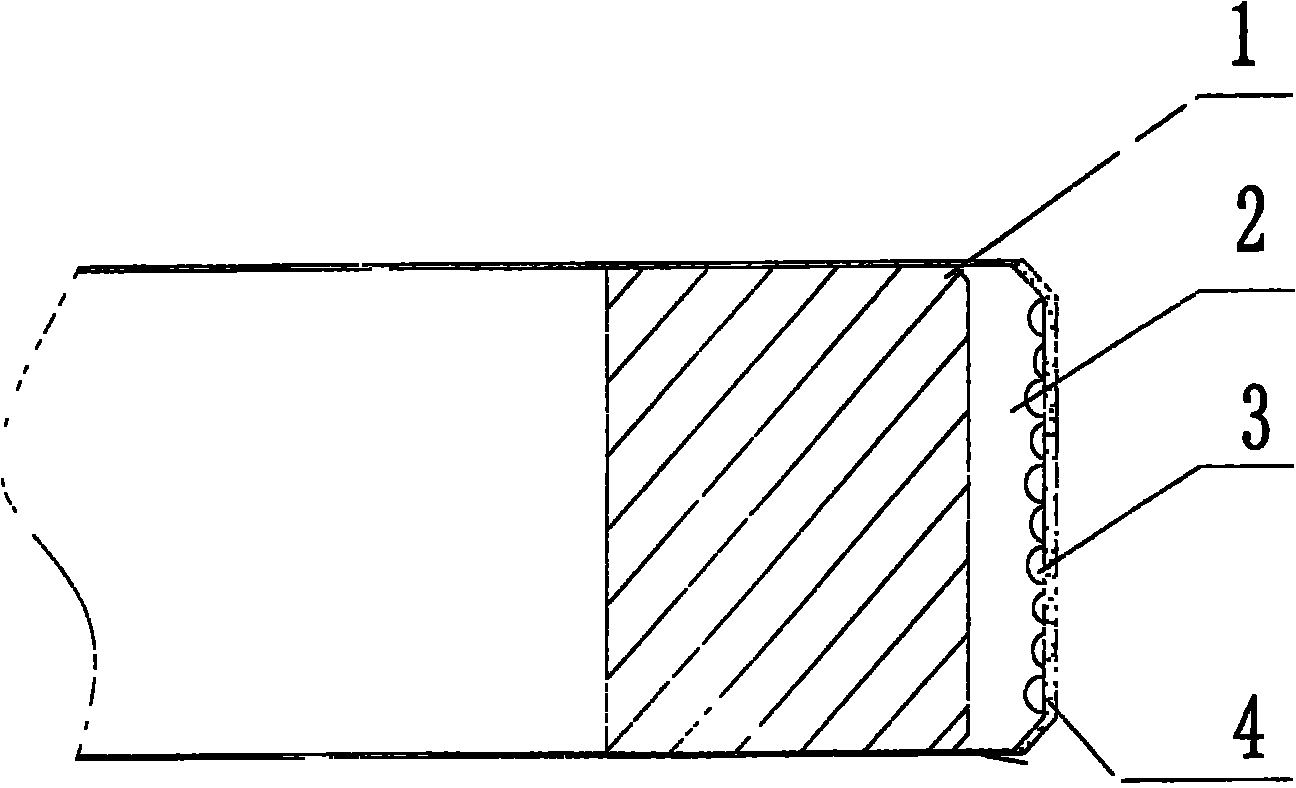

Piston ring and surface spongy tin plating technique thereof

A technology of piston rings and loose holes, which is applied to piston rings, engine components, mechanical equipment, etc., can solve the problems of slow heat conduction and uneven oil distribution, and achieve the effect of improving service life, uniform oil distribution and improving oil adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Take a number of piston rings and wrap the piston rings with round tiles, press them tightly with the mandrel to ensure that the two end faces of the piston rings are tightly fitted, seal and polish the outer circular surface with sealing glue to ensure good surface roughness , before entering the electroplating tank, use a sandblasting machine for sandblasting. Then wash in clean water at 60°C. Finally put it into the chrome plating bath of the following formula for chrome plating:

[0081] Chromium anhydride CrO 3 : 200g / L; sulfuric acid H 2 SO 4 : 2.2g / L; trivalent chromium (Cr 3+ ): 3.0g / L; acid ratio (CrO 3 / SO 4 2- ): 100 / 1.2; current density: 40A / dm 2 ; Bath temperature: 58 ° C; Plating time: 2.4h.

[0082] Take out the piston ring from the chrome-plating bath, wash it in water at 60°C, put it into equipment: dehydrogenate in an oven at 200°C, and the dehydrogenation time is 3 hours. Then return the piston ring to the machine shop for radial thickness a...

Embodiment 2

[0095] Take a number of piston rings and wrap the piston rings with round tiles, press them tightly with the mandrel to ensure that the two end faces of the piston rings are tightly fitted, seal and polish the outer circular surface with sealing glue to ensure good surface roughness , before entering the electroplating tank, use a sandblasting machine for sandblasting. Then wash in clean water at 65°C. After drying, put it into the chrome plating bath of the following formula for chrome plating:

[0096] Chromium anhydride CrO 3 : 210g / L; sulfuric acid H 2 SO 4 : 2.2g / L; trivalent chromium (Cr 3+ ): 3.2g / L; acid ratio (CrO 3 / SO 4 2- ): 100 / 1.2; current density: 42A / dm 2 ; Bath temperature: 58 ° C; Plating time: 2.4h.

[0097] Take out the piston ring from the chrome plating bath, wash it in water at 65°C, and put it into equipment: dehydrogenation in an oven at 200°C for 3.2 hours. Then return the piston ring to the machine shop for radial thickness and barrel surfa...

Embodiment 3

[0110] Take a number of piston rings and wrap the piston rings with round tiles, press them tightly with the mandrel to ensure that the two end faces of the piston rings are tightly fitted, seal and polish the outer circular surface with sealing glue to ensure good surface roughness , before entering the electroplating tank, use a sandblasting machine for sandblasting. Then wash in clean water at 65°C. After drying, put it into the chrome plating bath of the following formula for chrome plating:

[0111] Chromium anhydride CrO 3 : 210g / L; sulfuric acid H 2 SO 4 : 2.4g / L; trivalent chromium (Cr 3+ ): 3.4g / L; acid ratio (CrO 3 / SO 4 2- ): 100 / 1.2; current density: 45A / dm 2 ; Bath temperature: 60°C; Plating time: 2.6h.

[0112]Take out the piston ring from the chrome plating bath, wash it in water at 70°C, and put it into the equipment: remove hydrogen in an oven at 200°C, and the hydrogen removal time is 3.4h. Then return the piston ring to the machining workshop for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com