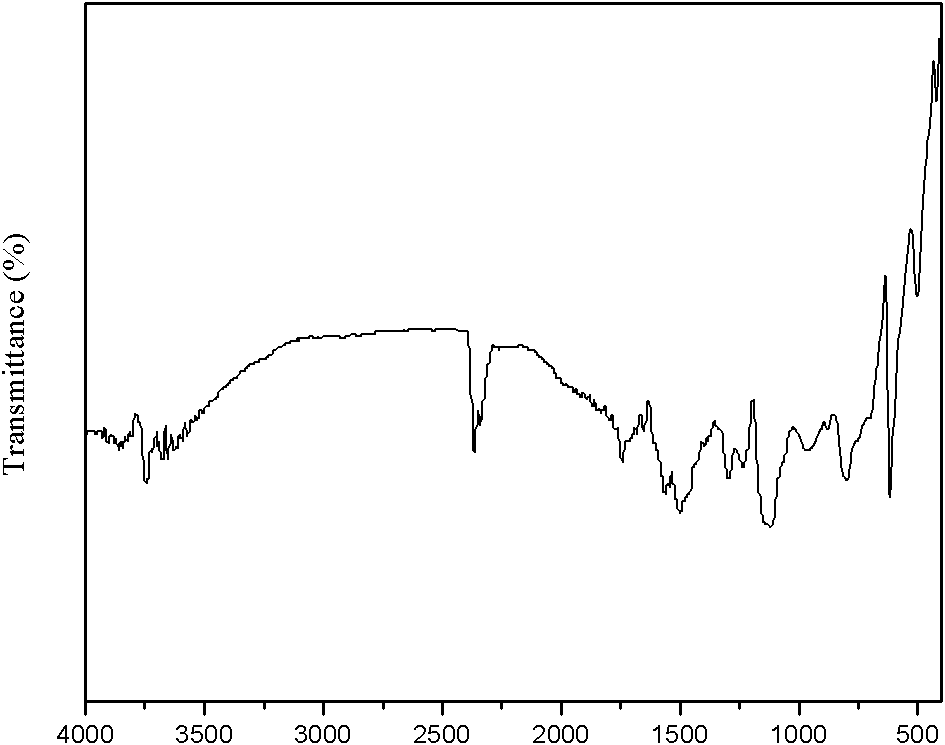

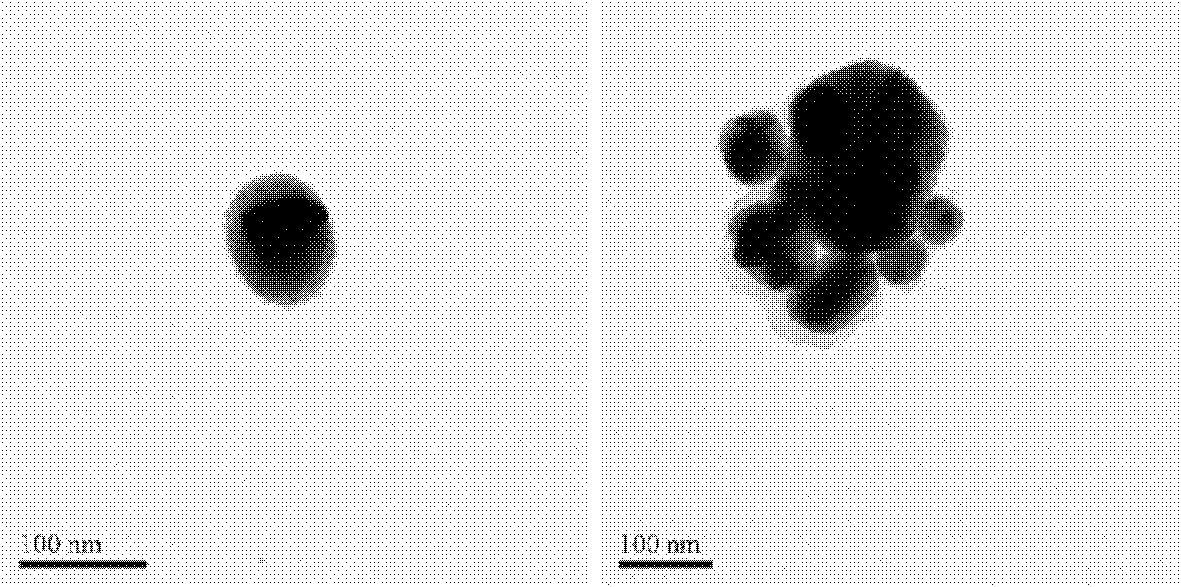

Method for preparing polyaniline/silver nanocomposite material

A composite material, silver nanotechnology, applied in the direction of electrolytic capacitors, electrical components, circuits, etc., to achieve the effect of solving dispersion problems, complementary advantages and strengthening, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] a. Weigh 0.305g of SDS and 0.459g of co-emulsifier n-hexanol into a beaker and add 60ml of distilled water for ultrasonic dispersion for 5 minutes. After the SDS is completely dissolved, stir for 5 minutes to make a clear and transparent microemulsion for use.

[0035]b. Take 45ml of microemulsion, and add 5mL of hydrogen peroxide with a mass fraction of 30% in a beaker to make a reducing solution, add 5ml of silver ammonia microemulsion (1M / L) dropwise to the reducing solution at a rate of 10-15 drops / min Prepare nano-silver particles in the experiment process, keep stirring, and the reaction time is 90min.

[0036] c. after the completion of the b reaction, add dropwise the pH of the nitric acid solution control system of 1M / L in the reaction system to be 7, then add 6.5ml of nitric acid (1M / L) solution containing 0.5g aniline and fully stir; Take 10ml of microemulsion, fully dissolve 1.23g of ammonium persulfate in it, and add it dropwise into a beaker at a rate of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com