Collagenolysis and regeneration method

A technology of collagen and collagen description, which is applied in the direction of animal/human protein, connective tissue peptide, single-component protein rayon, etc., can solve the problems of cumbersome extraction process, low extraction rate, and high cost, and achieve simplified preparation process and regeneration process Simple, easily recyclable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

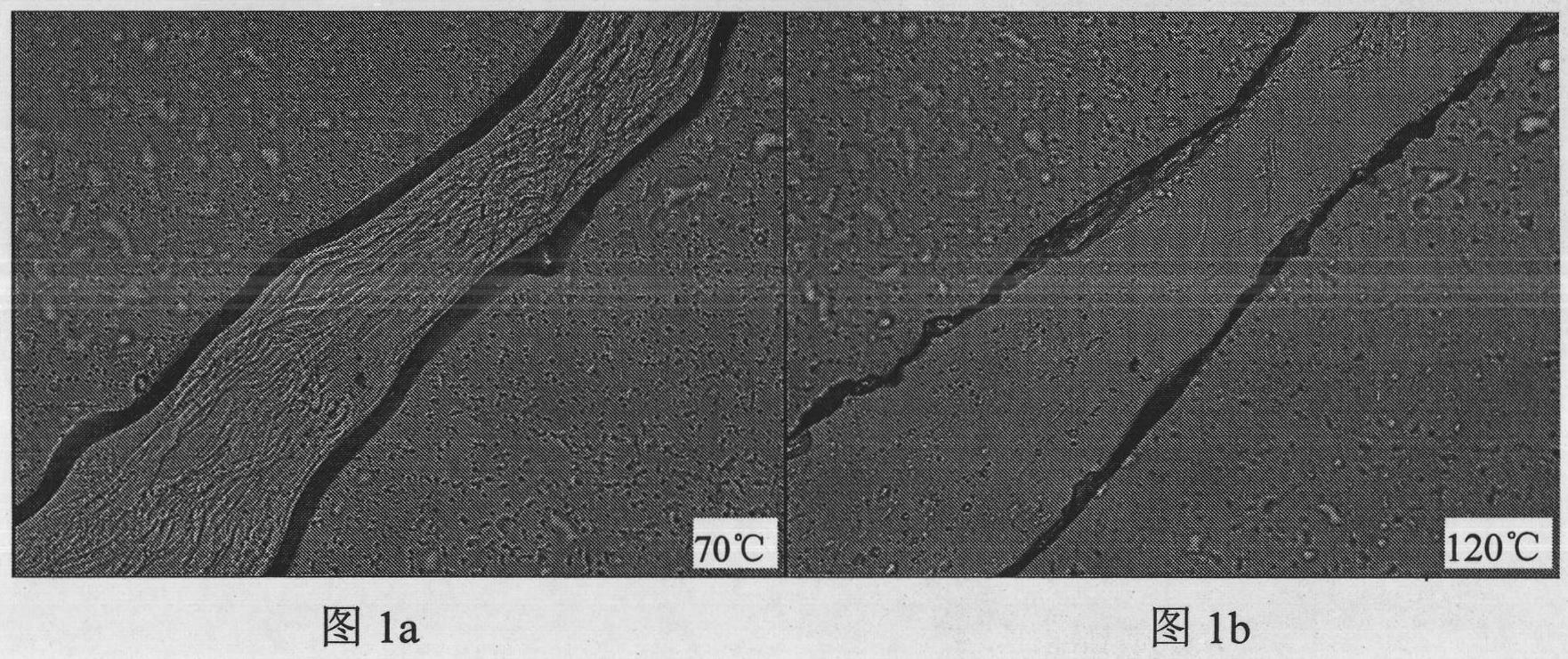

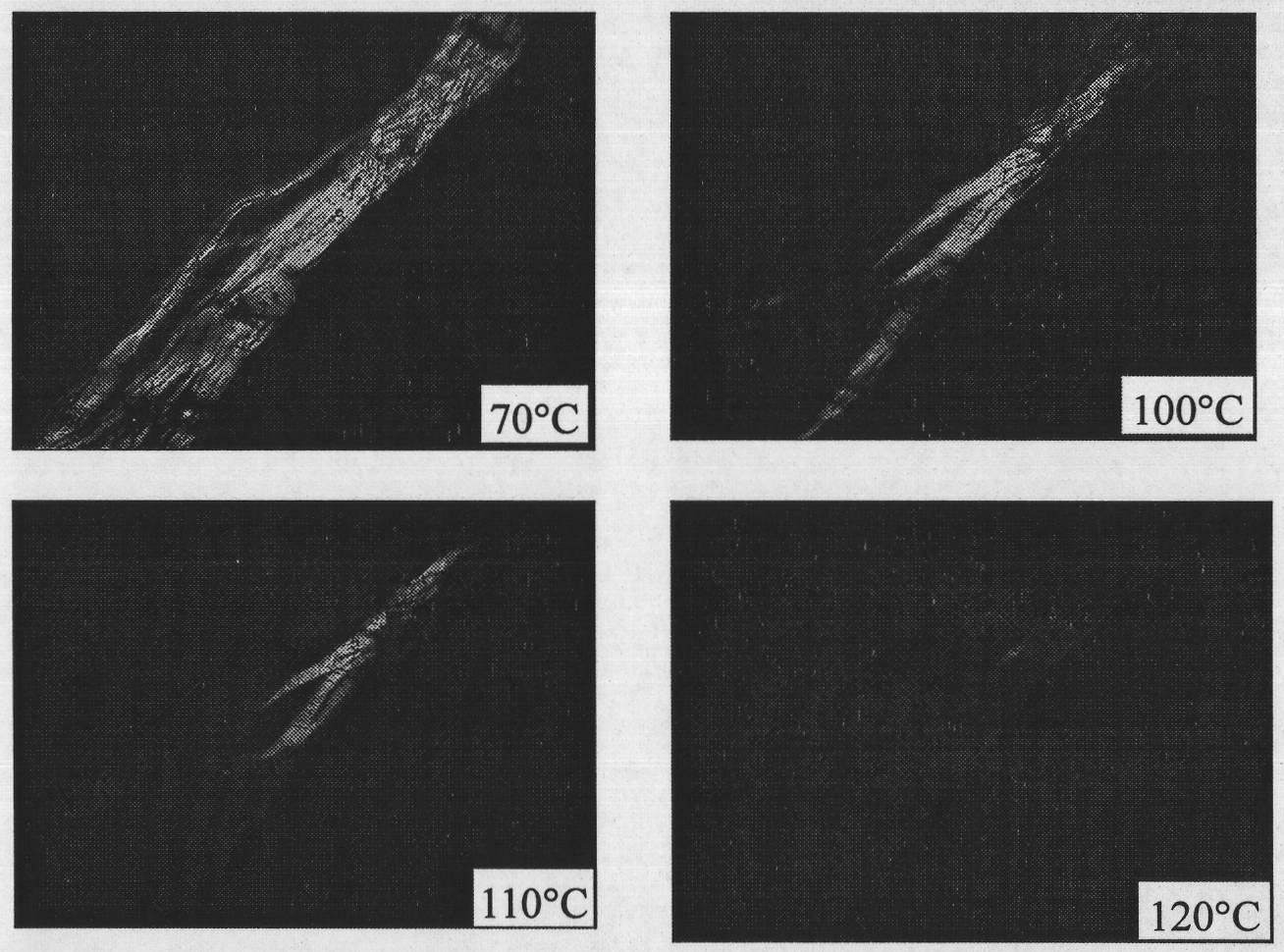

[0022] Weigh 0.56g skin powder fiber and 5.03g ionic liquid 1-methyl-3-butylchloroimidazole into a beaker, and heat up to 100°C while magnetically stirring; skin powder fiber gradually dissolves in the ionic liquid for 1.5h Afterwards, the solution is evenly dispersed and turbid. Continue to stir, and the solution gradually becomes clear until the skin powder fibers are completely dissolved.

[0023] Take a small amount of the prepared skin powder fiber ionic liquid solution, spread it evenly on the glass slide, immerse the slide in deionized water and let it stand, and the skin collagen will regenerate into a film. The membrane was repeatedly soaked in deionized water, the ionic liquid was thoroughly washed off, and the membrane was naturally dried in a ventilated place at room temperature to obtain a regenerated collagen membrane.

Embodiment 2

[0025] Weigh 0.25g skin powder fiber and 3.00g ionic liquid 1-butyl-3-methylchloroimidazole, add 0.30g deionized water, heat to 120°C in an oil bath, and carry out magnetic stirring; The aqueous ionic liquid was gradually dissolved, and after 1 hour, the solution was in a uniformly dispersed turbid state. Continue stirring, and the solution gradually became clear until the skin powder fibers were completely dissolved.

[0026] Take a small amount of prepared dermal fiber ionic liquid solution with a syringe, inject the solution into acetone, and regenerate collagen into fibers. Repeatedly soaking the fibers in acetone, thoroughly washing away the ionic liquid, and drying the fibers naturally in a ventilated place at room temperature to obtain regenerated collagen fibers.

Embodiment 3

[0028] Scrape off the corium layer of the pickled goatskin, neutralize it, and fully dry it in a vacuum oven at room temperature to obtain corium fiber. Weigh 0.6g of dermis fibers and 5.03g of ionic liquid 1-butyl-3-methylimidazole bromide, heat to 85°C in an oil bath, and carry out magnetic stirring; the fibers gradually dissolve in the ionic liquid, and after 6h, The solution is in a uniformly dispersed turbid state. Continue stirring until the solution gradually becomes clear until the fibers are completely dissolved.

[0029] Take a small amount of prepared dermal fiber ionic liquid solution with a syringe, drop the solution into acetone, and regenerate the skin collagen into a micropowder. The micropowder is obtained after suction filtration, and the micropowder is naturally dried in a ventilated place at room temperature to obtain regenerated skin collagen powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com