Silanization processing method of silicon powder and high damping concrete containing silanized silicon powder

A technology of silanization treatment and silanization of silicon powder, which is applied in the field of silanization treatment of silicon powder and high damping concrete containing silanization silicon powder, which can solve the problems of low damping capacity and increase impermeability and compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: The silanization treatment method of silicon powder in this embodiment is as follows: 1. Place the silicon powder in a desiccator to constant dryness; 2. Immerse the silicon powder processed in step one to a mass concentration of 0.6%, In KH 550 silane coupling agent solution at 80℃ for 1h, then filter and dry; 3. Dry the silicon powder treated in step 2 at 105℃ for 12h, and then dry to constant weight to obtain silanized silicon powder.

[0021] The mechanism of action of the silane coupling agent in this embodiment is as follows:

[0022] The chemical formula of silane coupling agent is RSiX 3 , Where R is an organic group and X is a hydrolyzable group.

[0023] First, when the silicon powder is immersed in the KH 550 silane coupling agent solution, the silane coupling agent is wrapped on the surface of the silicon powder, mainly for physical adsorption.

[0024] Secondly, the X group in the silane coupling agent is hydrolyzed to form silanol, the reac...

specific Embodiment approach 2

[0034] Specific embodiment two: the high damping concrete containing silanized silicon powder per cubic meter in this embodiment is highly efficient from 480kg cement, 28.8kg of silanized silicon powder prepared in embodiment one, 200kg water, 638kg sand, 1042kg stones and 2.4kg FDN Composition of water reducing agent.

[0035] The high damping concrete containing silanized silicon powder in this embodiment is made by mixing the components of the high damping concrete containing silanized silicon powder.

[0036] The cement used in this embodiment is 32.5 ordinary Portland cement, the basic physical and mechanical properties of 32.5 ordinary Portland cement are shown in Table 2, and the chemical composition (%) of 32.5 ordinary Portland cement is shown in Table 3.

[0037] Table 2

[0038]

[0039] table 3

[0040]

[0041] The sand used in this embodiment is medium sand, and the grain gradation of medium sand is zone II gradation. The performance indexes of sand are shown in Table 4: ...

specific Embodiment approach 3

[0047] Specific implementation mode 3: In this embodiment, 9 concrete beams are prepared according to the ratio in Table 6, and the size of the specimen is 60×60×900mm 3 , Each test piece is 0.06×0.006×0.9=0.00324m 3 , That is, each test piece is 3.24 liters. We make 4 liters according to the ratio. P in Table 6 stands for benchmark concrete, SF stands for benchmark concrete mixed with unmodified silica fume, and GSF stands for specific embodiment two containing silanized silica fume High damping concrete.

[0048] Table 6

[0049]

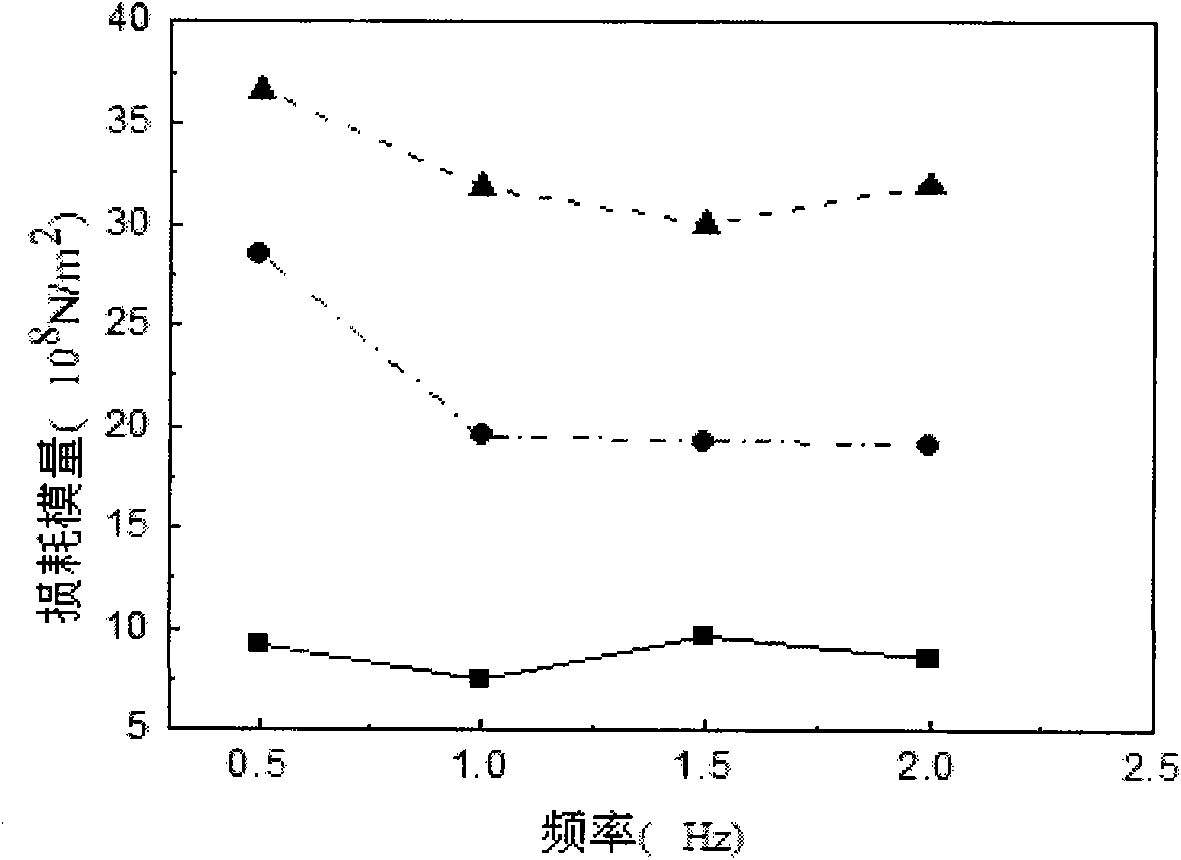

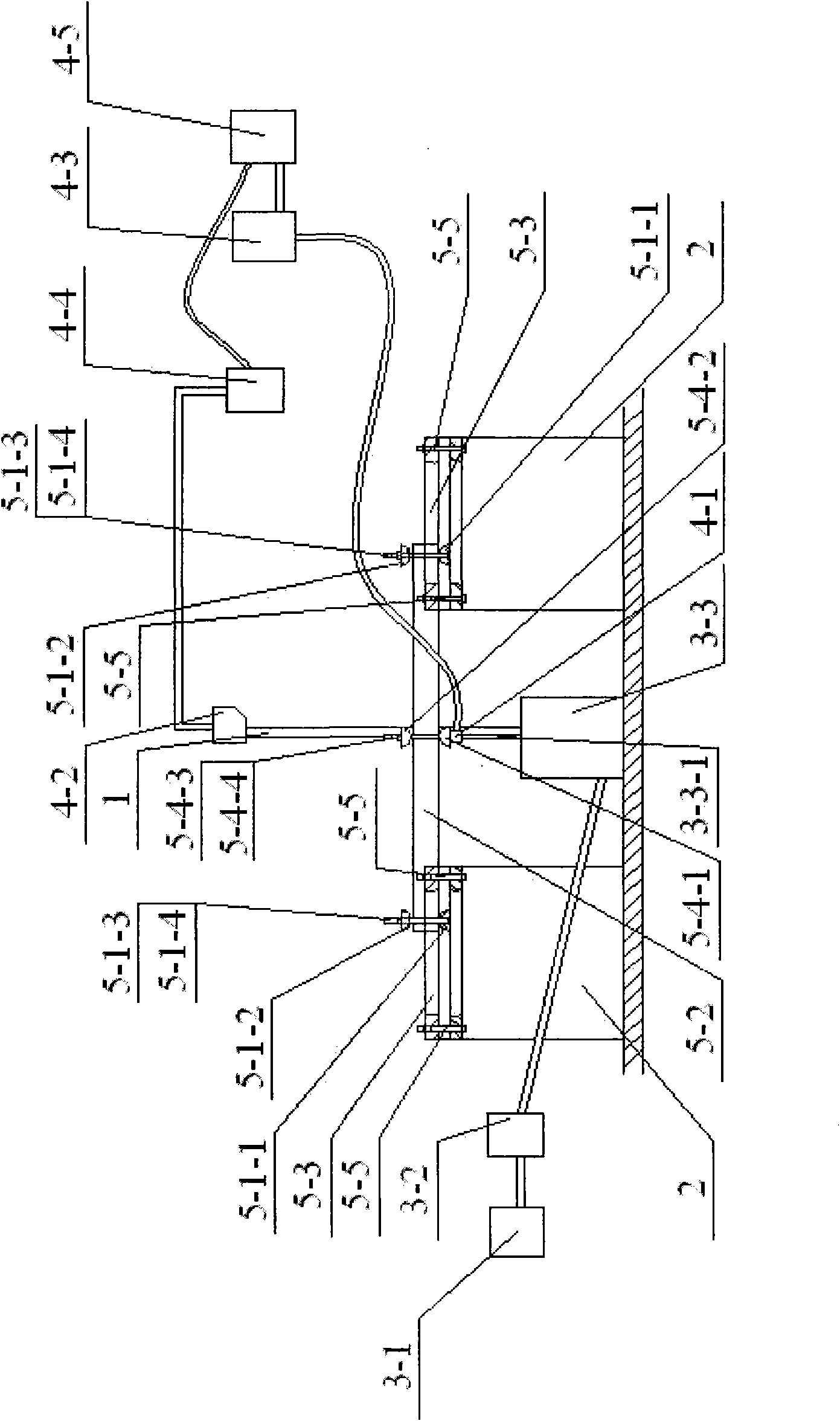

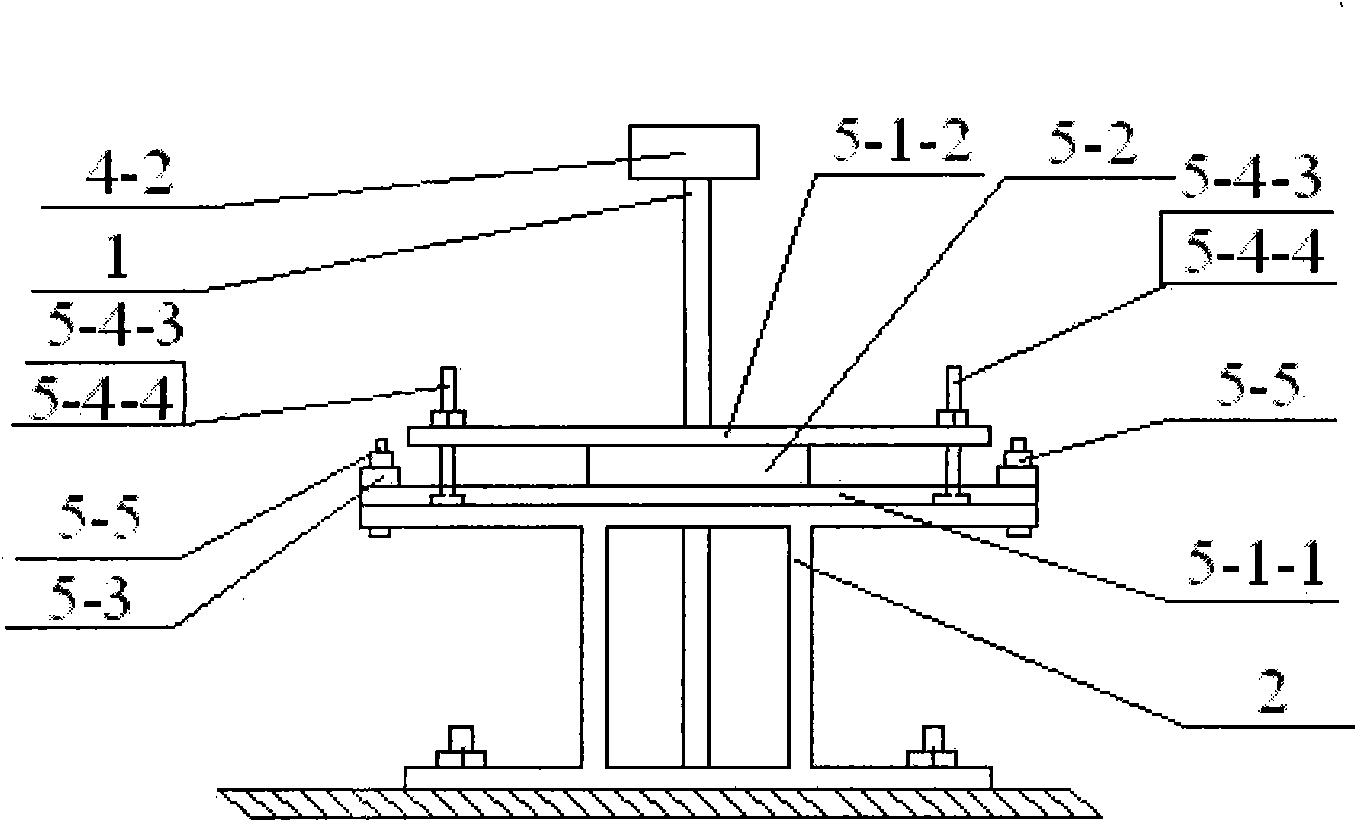

[0050] Three kinds of concrete beams prepared according to the proportions in Table 6 were respectively tested with a three-point bending beam type large-size material damping test device:

[0051] The cross-sectional dimension of the three-point bending beam is 60mm×60mm×900mm. Input the sinusoidal excitation signal, obtain the displacement response of the sample from the data acquisition system, use MATLAB programming to obtain the phase difference be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com