High-temperature cyanogen-free gold loaded carbon desorption system and control method thereof

A gold-loaded carbon and desorption technology, which is applied in the direction of separation methods, chemical instruments and methods, and process efficiency improvement, to achieve the effect of making full use of heat energy and ensuring no loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

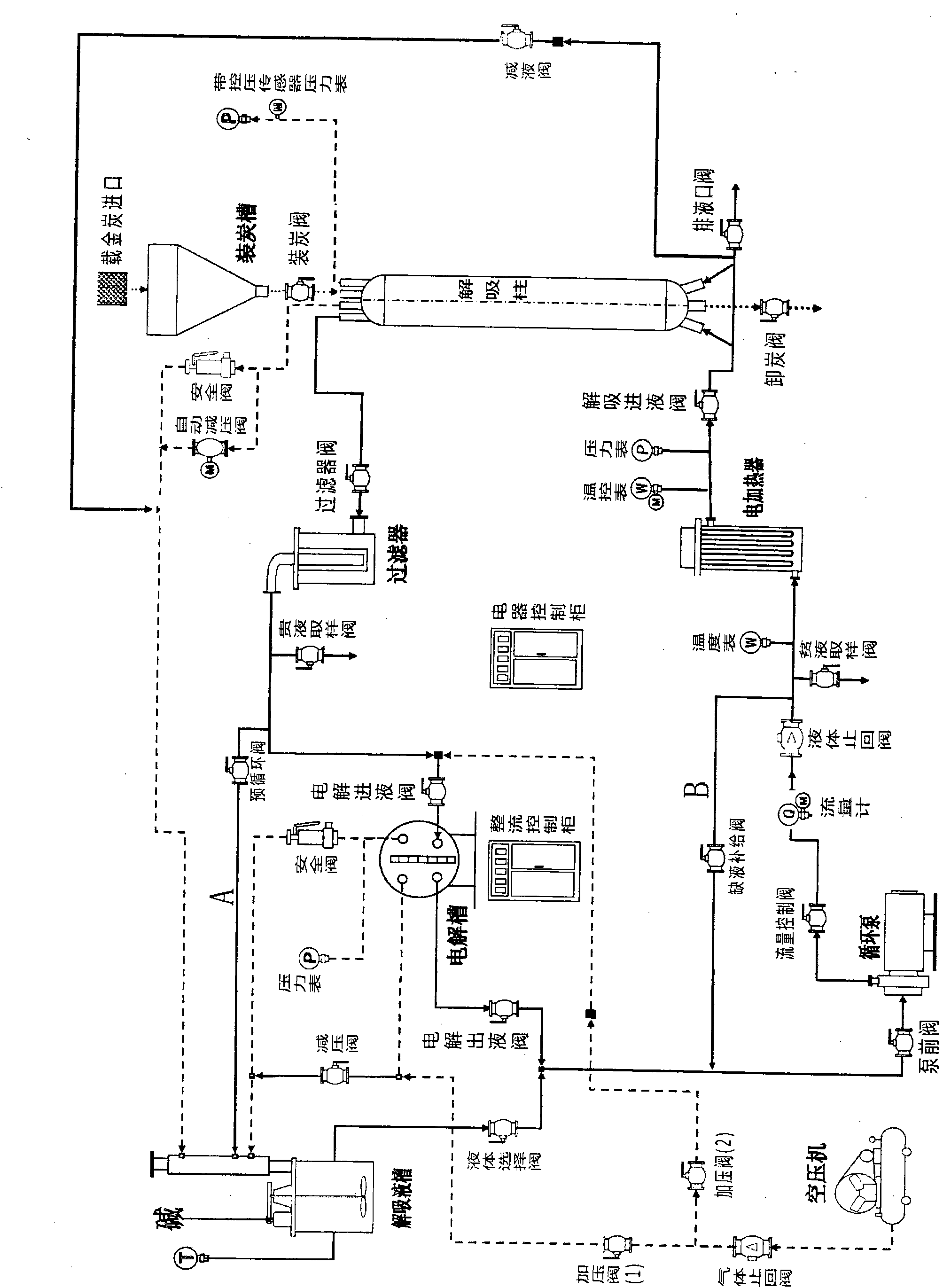

[0035] Such as figure 2 As shown, the high-temperature cyanide-free gold-loaded carbon desorption system of the present invention includes existing desorption columns, electric heaters, electrolytic cells, circulation pumps, desorption liquid tanks, air compressors, and connecting pipes and control valves of the above-mentioned components. The innovations of the present invention are: 1) a solution circulation channel A (to change the process control to ensure product safety) is set, one end of which is connected to the pipeline between the filter and the electrolytic liquid inlet valve, and the other end is connected to the desorption Liquid tank; 2) An electrolytic tank high-pressure liquid shortage supply channel B is provided, one end of which is connected to the pipeline between the electric heater and the liquid check valve, and the other end is connected to the pipeline between the electrolytic liquid outlet valve of the pump front valve.

[0036] The control method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com