Preparation method of high barrier light-proof, preservative and environment-friendly polyester material

A kind of polyester material, environment-friendly technology, applied in the field of polyester material preparation, can solve the problems of damage delamination, poor dispersion of MMT, poor barrier property, etc., and achieve the effect of improving melt strength, good dispersion and promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention relates to a method for preparing a high-barrier, light-proof, fresh-keeping and environment-friendly polyester material. The method includes the following process:

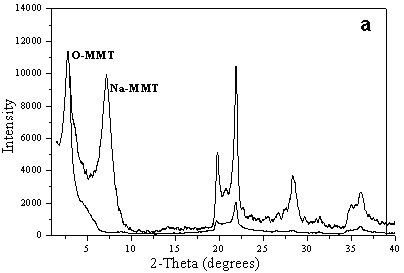

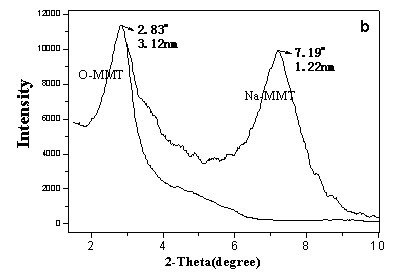

[0043] Step 1. Pre-modification of montmorillonite to obtain organic montmorillonite loaded with main titanium catalyst

[0044] This step mainly includes two main processes of organic modification and supporting the main titanium-based catalyst with stable reactivity, and the preparation process is as follows:

[0045] a) Add 10 parts by weight of montmorillonite (Zhangjiakou Qinghe Chemical Plant) with a cation exchange capacity of 100meq / 100g to 100 parts by weight of ethylene glycol, and stir at room temperature to obtain an ethylene glycol solution of montmorillonite.

[0046] b) Stir 1 part by weight of the catalyst in 100 parts by weight of ethylene glycol at 60°C for 12 hours, then add it into the ethylene glycol solution of montmorillonite obtained in step 1, stir for 3 hours and the...

Embodiment 1

[0063] The invention relates to a method for preparing a high-barrier, light-proof, fresh-keeping and environment-friendly polyester material. The method includes the following process:

[0064] Step 1. Pre-modification of montmorillonite to obtain organic montmorillonite loaded with main titanium catalyst

[0065] This step mainly includes two main processes of organic modification and supporting the main titanium-based catalyst with stable reactivity, and the preparation process is as follows:

[0066] a) Montmorillonite with a cation exchange capacity of 50meq / 100g (Zhangjiakou Qinghe Chemical Plant)

[0067] Add 0.3 parts by weight to 30 parts by weight of ethylene glycol, and stir at room temperature to obtain an ethylene glycol solution of montmorillonite.

[0068] b) Stir 0.005 parts by weight of the catalyst in 3 parts by weight of ethylene glycol at 30°C for 12 hours, then add it to the ethylene glycol solution of montmorillonite obtained in step 1, stir for 0.3 hour...

Embodiment 2

[0079] The invention relates to a method for preparing a high-barrier, light-proof, fresh-keeping and environment-friendly polyester material. The method includes the following process:

[0080] Step 1, organic modification of montmorillonite to obtain organic montmorillonite loaded with main titanium series catalyst

[0081] This step mainly includes organic modification and loading of main titanium-based catalyst with stable reaction activity.

[0082] The main process is as follows:

[0083] a) Add 10 parts by weight of montmorillonite (Zhangjiakou Qinghe Chemical Plant) with a cation exchange capacity of 100meq / 100g to 100 parts by weight of ethylene glycol, and stir at room temperature to obtain an ethylene glycol solution of montmorillonite.

[0084] b) Stir 1 part by weight of the catalyst in 100 parts by weight of ethylene glycol at 60°C for 18 hours, then add it into the ethylene glycol solution of montmorillonite obtained in a), stir for 3 hours and then use a centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com