Production method of isocyanuric acid

An isocyanuric acid and production method technology, applied in the direction of organic chemistry, etc., can solve the problems of non-compliance with clean production and environmental protection requirements, large steam consumption, low absorption efficiency, etc., to expand the industrial chain, reduce steam consumption, thermal energy low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

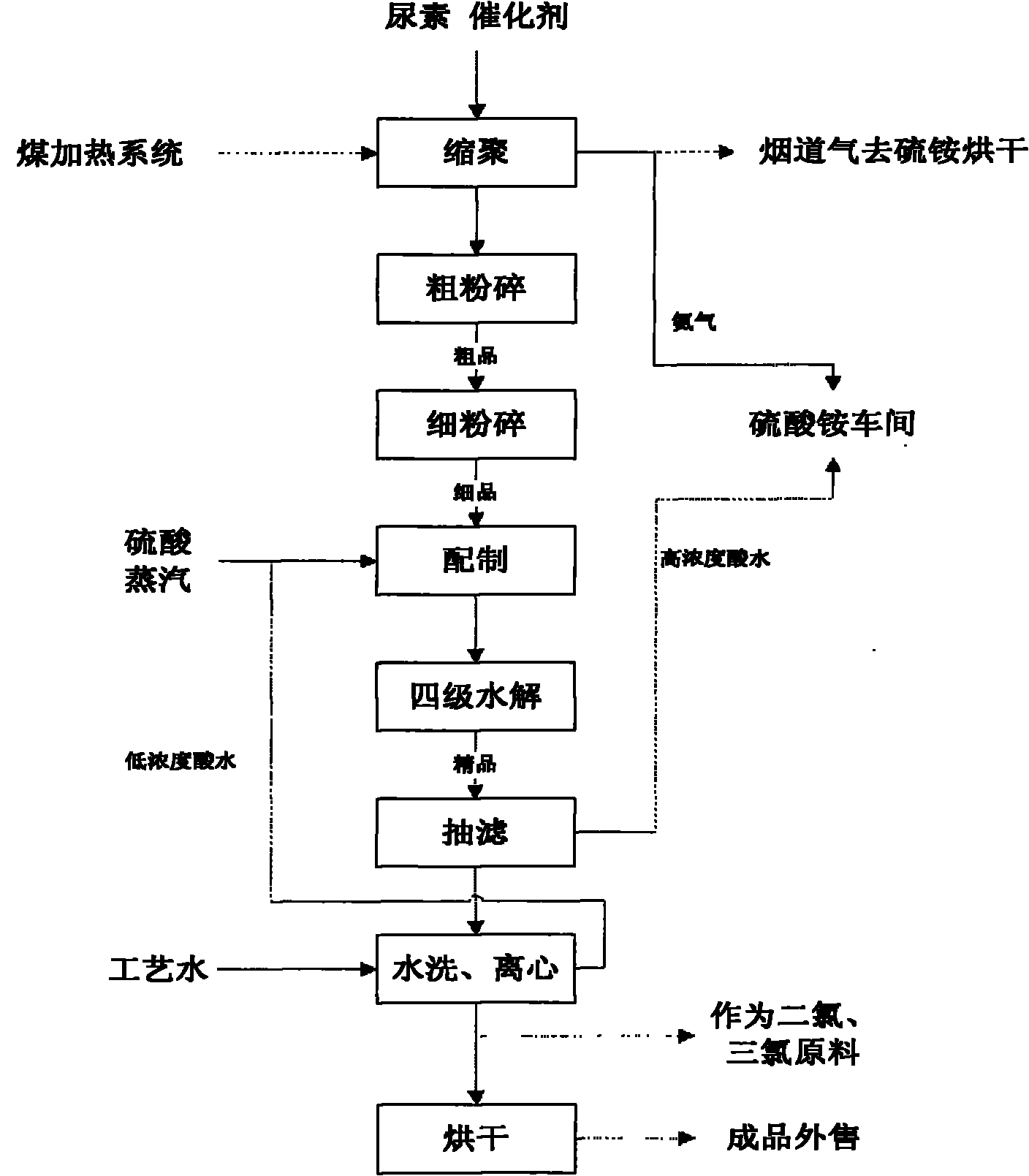

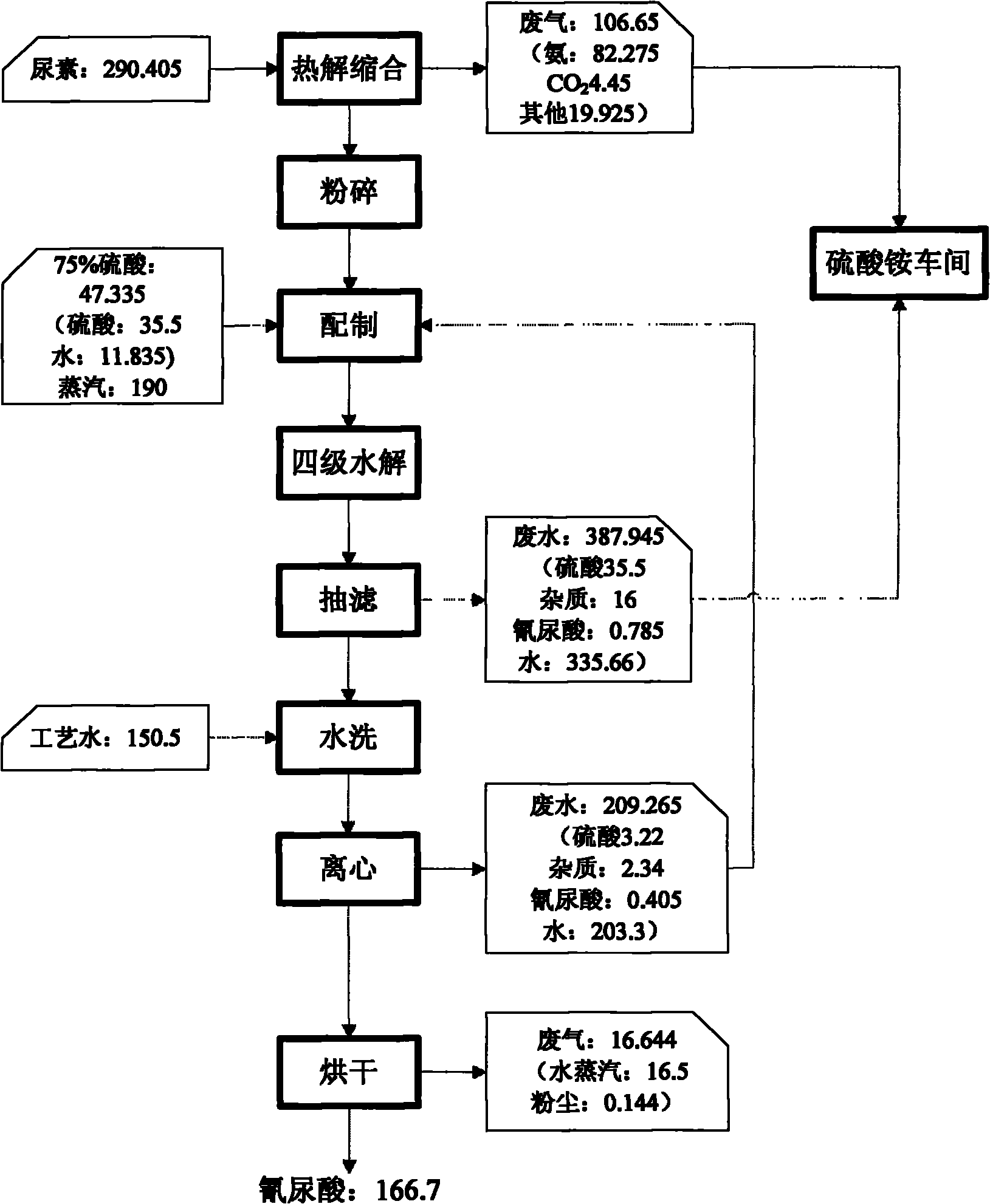

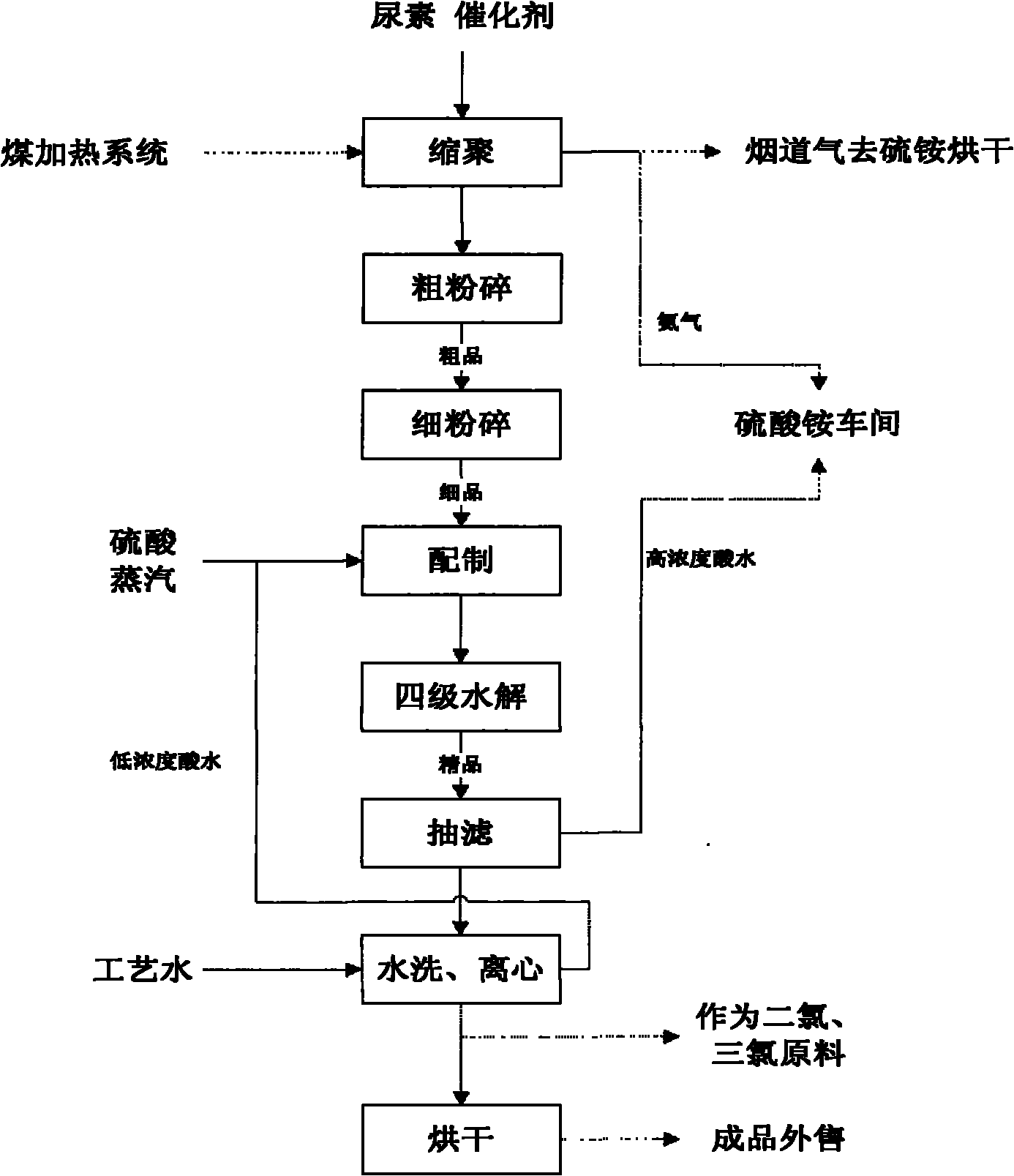

Method used

Image

Examples

Embodiment 1

[0045] 1.5 tons of urea and 1.5 kilograms of ammonium chloride are polycondensed in the polymerization furnace, and the material after the furnace is coarsely crushed and finely crushed to obtain the isocyanuric acid fine material. 1.2 tons of isocyanuric acid fine material, 1400 liters of mass percent are Put 25% sulfuric acid into the first batching tank and the second batching tank respectively, then connect the batching tank, mix the two evenly, and drive the feed liquid into the 3000-liter first-stage pressurized reaction kettle by the power pump, and pass through at the same time Enter steam to heat the feed liquid. The pressure in the reactor is 0.4MPa and the temperature is 138°C. Under this condition, the feed liquid is instantly hydrolyzed. After the first-stage pressurized reactor is full, the feed liquid enters 3000 m The hydrolysis reaction continues to occur in the secondary pressurized reactor. At this time, the pressure in the secondary pressurized reactor is 0....

Embodiment 2

[0051] 3 tons of urea and 6 kilograms of ammonium chloride are polycondensed in the polymerization furnace, and the material after the furnace is coarsely crushed and finely crushed to obtain the isocyanuric acid fine material. 2.4 tons of isocyanuric acid fine material and 2800 liters of mass percent are Put 25% sulfuric acid into the first batching tank and the second batching tank respectively, then connect the batching tank, mix the two evenly, and then drive the feed liquid into a 6000-liter first-stage pressurized reactor by a power pump, and pass Enter steam to heat the feed liquid. The pressure in the reactor is 0.4MPa and the temperature is 135°C. Under this condition, the feed liquid is instantly hydrolyzed. After the first-stage pressurized reactor is full, the feed liquid enters 6000 m The hydrolysis reaction continues to occur in the secondary pressurized reactor. At this time, the pressure in the secondary pressurized reactor is 0.3MPa and the temperature is 133°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com