Method for preparing corrosion-resistant colored decorative film

A decorative film and corrosion-resistant technology, used in special decorative structures, decorative arts, chemical instruments and methods, etc., can solve the problems of complex process and single color, and achieve the effect of simple process, low deposition temperature, and conducive to popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

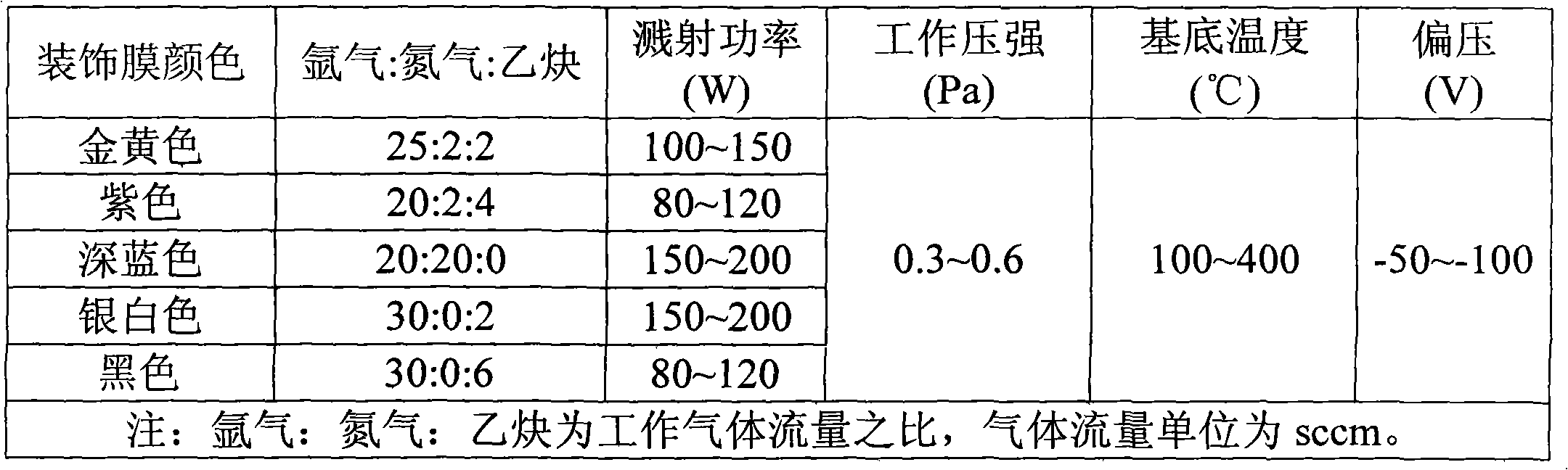

[0014] Example 1: A golden yellow corrosion-resistant decorative film was prepared by radio frequency magnetron sputtering.

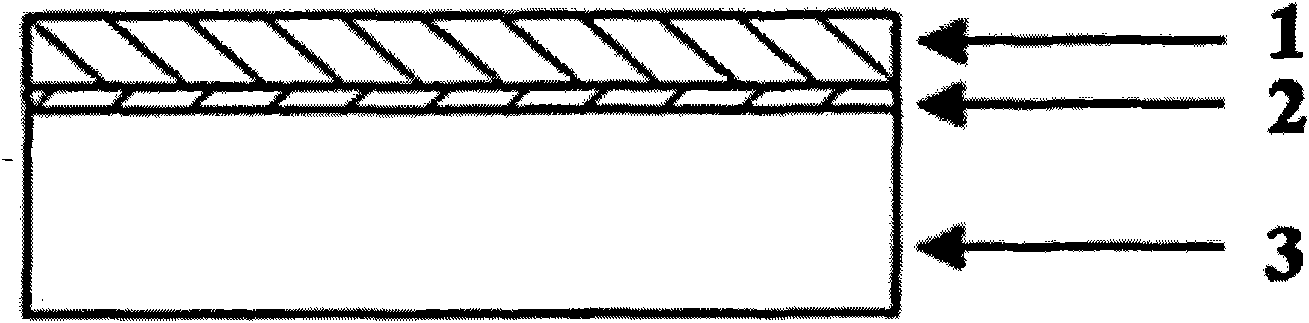

[0015] The purity of the titanium target for sputtering is 99.9%, and the relative density is ~0.90. Correctly install the titanium target in the target gun (as shown in Figure 1), adjust the angle between the target gun and the vertical direction to ~30°, and evacuate until the background vacuum degree of the vacuum chamber is higher than 2.0×10 -4 Pa. The copper-zinc alloy (atomic ratio Cu:Zn=6:4) decoration is used as the substrate, and the substrate temperature is 400°C.

[0016] The first layer of film deposition process: 20sccm (sccm means standard milliliter per minute) argon gas is passed into the vacuum chamber, the pressure in the vacuum chamber is adjusted to 0.5Pa, the bias voltage is adjusted to -100V, the sample rotation rate is 10 rpm, radio frequency The power supply was adjusted to 100W, and the deposition time was controlled to be 5m...

Embodiment 2

[0018] Example 2: Preparation of a purple corrosion-resistant decorative film by radio frequency magnetron sputtering.

[0019] The copper-zinc alloy (ratio of atomic number Cu:Zn=6:4) decoration is used as the substrate, the temperature of the substrate is 200° C., and the rest are the same as in Example 1.

[0020] The first layer film deposition process conditions are the same as in Example 1.

[0021] The second film deposition process conditions are: the working atmosphere is 25sccm argon, 2sccm nitrogen and 4sccm acetylene; the working pressure is 0.5Pa; the radio frequency power supply is 100W; Deposited under this condition for 60 minutes, the thickness of the decorative film is about 700nm, the color is purple and has metallic luster.

Embodiment 3

[0022] Example 3: A dark blue corrosion-resistant decorative film was prepared by radio frequency magnetron sputtering.

[0023] The zinc-aluminum alloy (ratio of atomic number Zn:Al=9:1) decoration is used as the substrate, the temperature of the substrate is 200° C., and the rest are the same as in Example 1.

[0024] The first layer film deposition process conditions are the same as in Example 1.

[0025] The second film deposition process conditions are: the working atmosphere is 20sccm argon and 20sccm nitrogen; the working pressure is 0.4Pa; the radio frequency power supply is 180W; Deposited under this condition for 60 minutes, the thickness of the decorative film is about 1.2 μm, the color is dark blue and has metallic luster.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com