Processing method of emery cutter

A processing method, the technology of corundum, which is applied in the field of corundum tools, can solve the problems of high grinding force and short service life of corundum tools, and achieve the effects of increased bonding strength, improved mutual suction ability, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

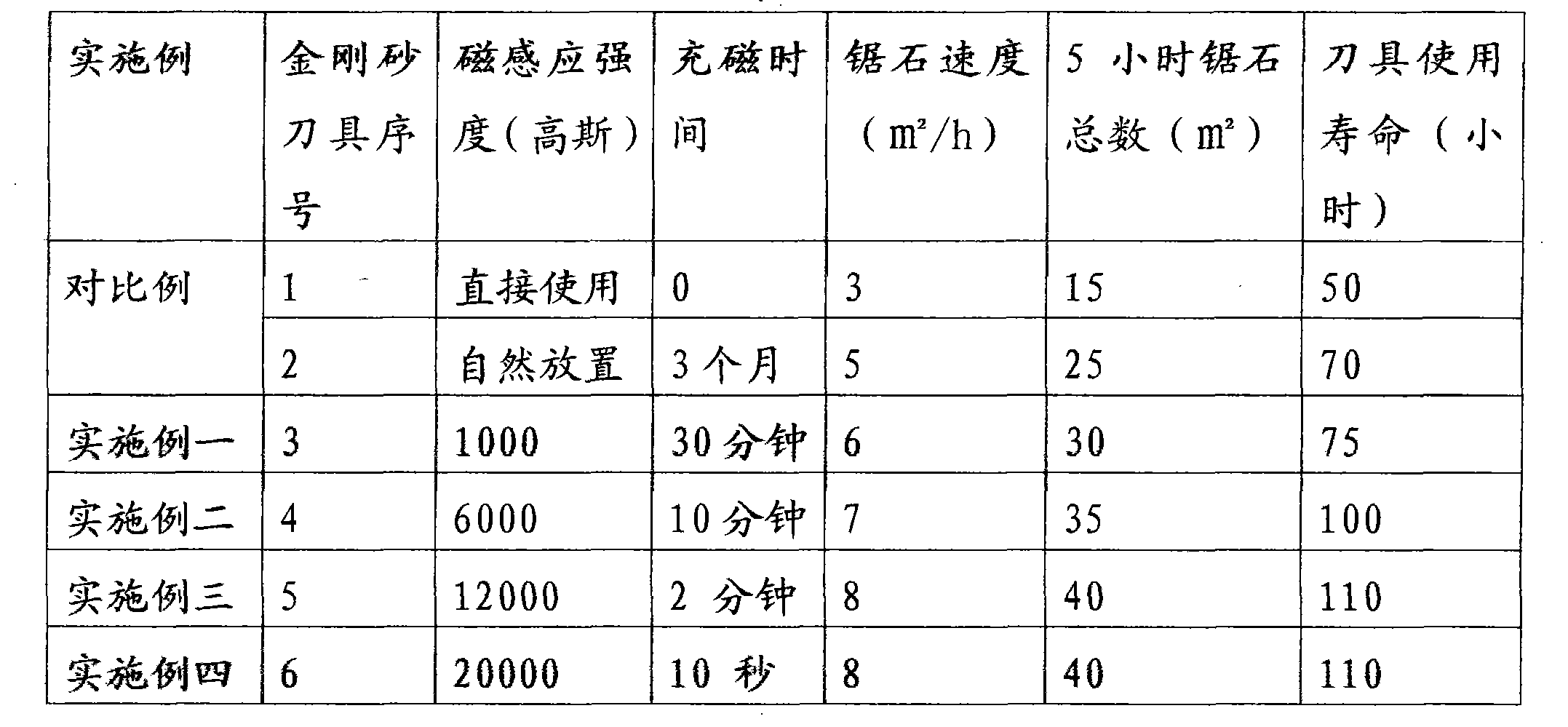

[0019] Take the emery cutter head group 3, weld and fix this group of cutter heads to the circular saw body of a stone sawing machine to obtain an emery cutter 3, place the emery cutter 3 in a magnetic field for magnetization, and the magnetic field The magnetic induction intensity is 1000 Gauss, and the magnetization treatment time is 30 minutes. Use after magnetization treatment, record the sawing speed, the number of sawing stones per unit time and the service life of the tool during use, as shown in Table 1.

Embodiment 2

[0021] Take the emery cutter head group 4, weld and fix this group of cutter heads to the circular saw body of a stone sawing machine to obtain an emery cutter 4, place the emery cutter 4 in a magnetic field for magnetization, and the magnetic field The magnetic induction intensity is 6000 Gauss, and the magnetization treatment time is 10 minutes. Use after magnetization treatment, record the sawing speed, the number of sawing stones per unit time and the service life of the tool during use, as shown in Table 1.

Embodiment 3

[0023] Take the emery cutter head group 5, weld and fix this group of cutter heads to the circular saw body of a stone sawing machine to obtain an emery cutter 5, and place the emery cutter 5 in a magnetic field for magnetization treatment, the magnetic field The magnetic induction intensity is 12000 Gauss, and the magnetization treatment time is 2 minutes. Use after magnetization treatment, record the sawing speed, the number of sawing stones per unit time and the service life of the tool during use, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com