Paper shredder with function of discharging paper

A paper shredder and paper shredding technology, which is applied in the direction of presses, grain processing, manufacturing tools, etc., can solve the problems of large space occupied by paper shredders, large trash cans, large volume of paper shredders, etc., to achieve clean paper scraps Simple and convenient, the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A paper discharge and collection method for a paper shredder in this embodiment includes a paper shredding step, a paper discharge step and a paper dust collection step, and each step is as follows:

[0063] In the paper shredding step, the paper is shredded into paper scraps by the paper shredder head 1;

[0064] discharge step,

[0065] A paper discharge device with a paper dust output interface 5 is arranged at the bottom of the shredder head 1, and the paper discharge device closes the bottom surface of the shredder head or at least closes the paper outlet on the bottom surface of the shredder head 1,

[0066] The paper discharge device receives the paper scraps falling from the paper outlet 3 of the shredder head 1,

[0067] The paper discharge device transports the paper scraps to the paper scrap output interface 5;

[0068] confetti collection steps,

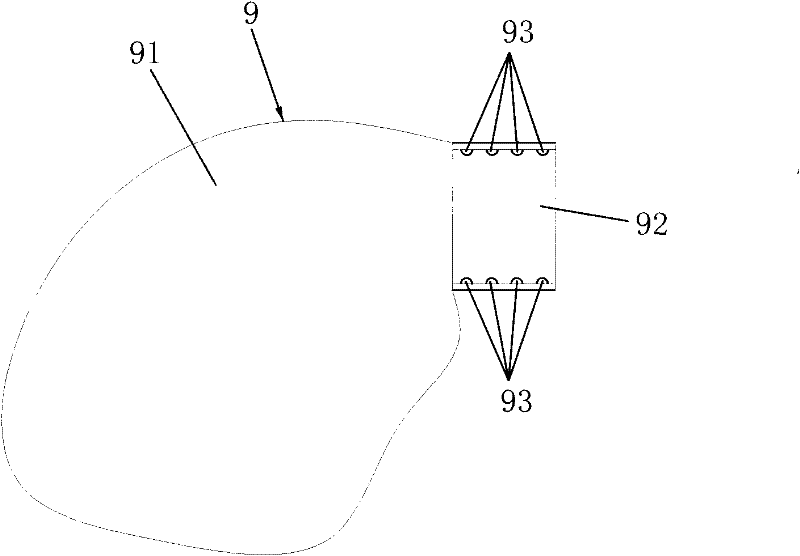

[0069] An anti-off device for fixing the paper dust collection bag 9 is provided at the outer end of the pape...

Embodiment 2

[0077] The first embodiment of the paper shredder with paper discharge function of the present invention is as follows: Figures 1 to 5 As shown, it includes a shredder head 1, the top of the shredder head 1 is provided with a paper inlet 2, the bottom of the shredder head 1 is provided with a paper outlet 3, and the bottom of the shredder head 1 is provided with a paper discharge shell Body 4, the top surface of the paper discharge case 4 is open to form a paper receiving port for receiving the paper scraps dropped from the paper outlet 3, and the paper discharge case 4 is provided with a paper bag for connecting the paper dust collection bag 9 or the paper dust delivery pipe. The chip output interface 5, the cavity of the paper discharge housing 4 is provided with a push plate 42 for discharging the fallen paper scraps to the paper waste output interface 5 and for driving the push plate 42 in the paper discharge housing 4. The screw mandrel 41 of reciprocating motion, the sc...

Embodiment 3

[0106] The second embodiment of the paper shredder with paper discharge function of the present invention is as follows: Figure 6 As shown, it includes a shredder head 1, the top of the shredder head 1 is provided with a paper inlet 2, the bottom of the shredder head 1 is provided with a paper outlet 3, and the bottom of the shredder head 1 is provided with a paper discharge shell Body 4, the top surface of the paper discharge case 4 is open to form a paper receiving port for receiving the paper scraps dropped from the paper outlet 3, and the paper discharge case 4 is provided with a paper bag for connecting the paper dust collection bag 9 or the paper dust delivery pipe. A scrap output interface 5, a screw 6 for discharging fallen paper scraps to the scrap output interface 5 is provided in the cavity of the paper discharge housing 4, and the first end of the screw 6 extends into the scrap output interface 5 .

[0107] When the paper is shredded, the paper dust falls from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com