Method for preparing dimethyl succinate

A technology for dimethyl succinate and maleic anhydride, which is applied in the field of preparing dimethyl succinate, and can solve the problems of slow reaction speed of dimethyl succinate, difficulty in product separation and purification, and difficulty in performing thorough reaction, etc. problems, to achieve the effect of strong equipment applicability, flexible operation and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

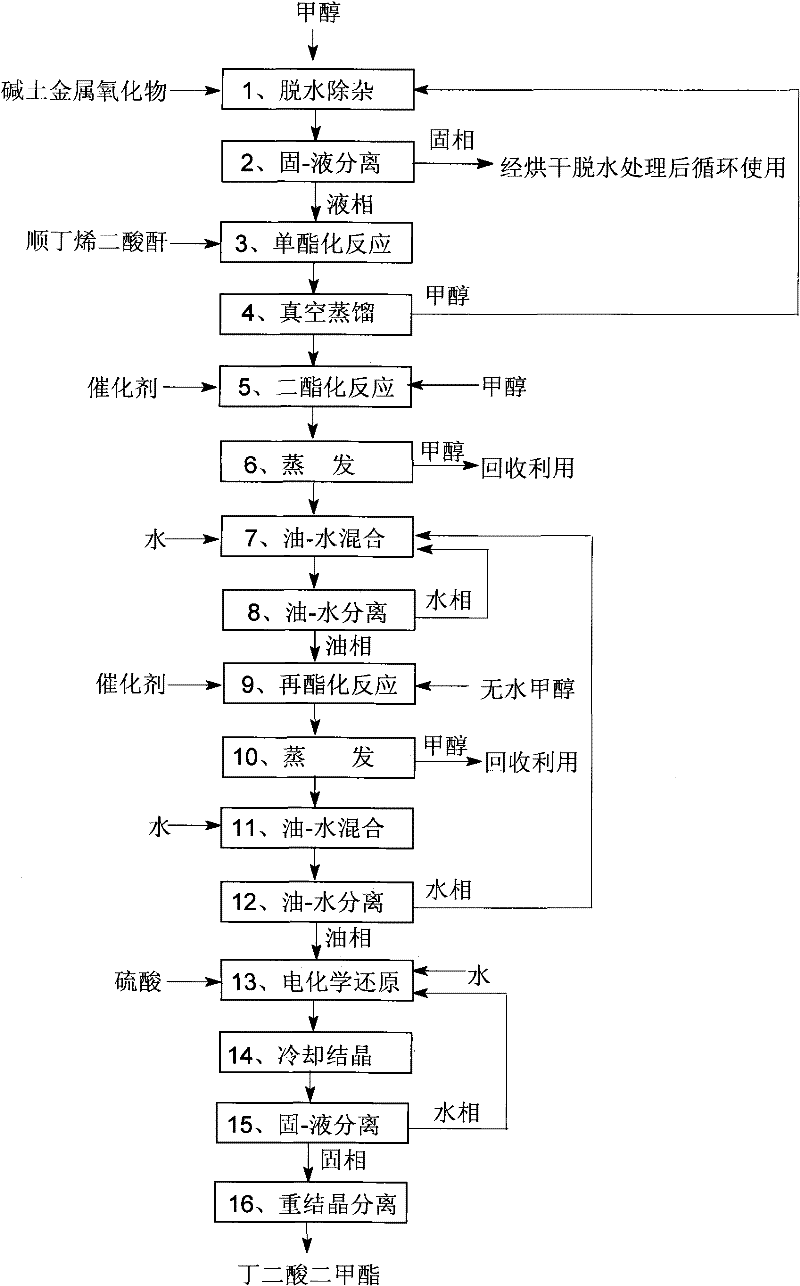

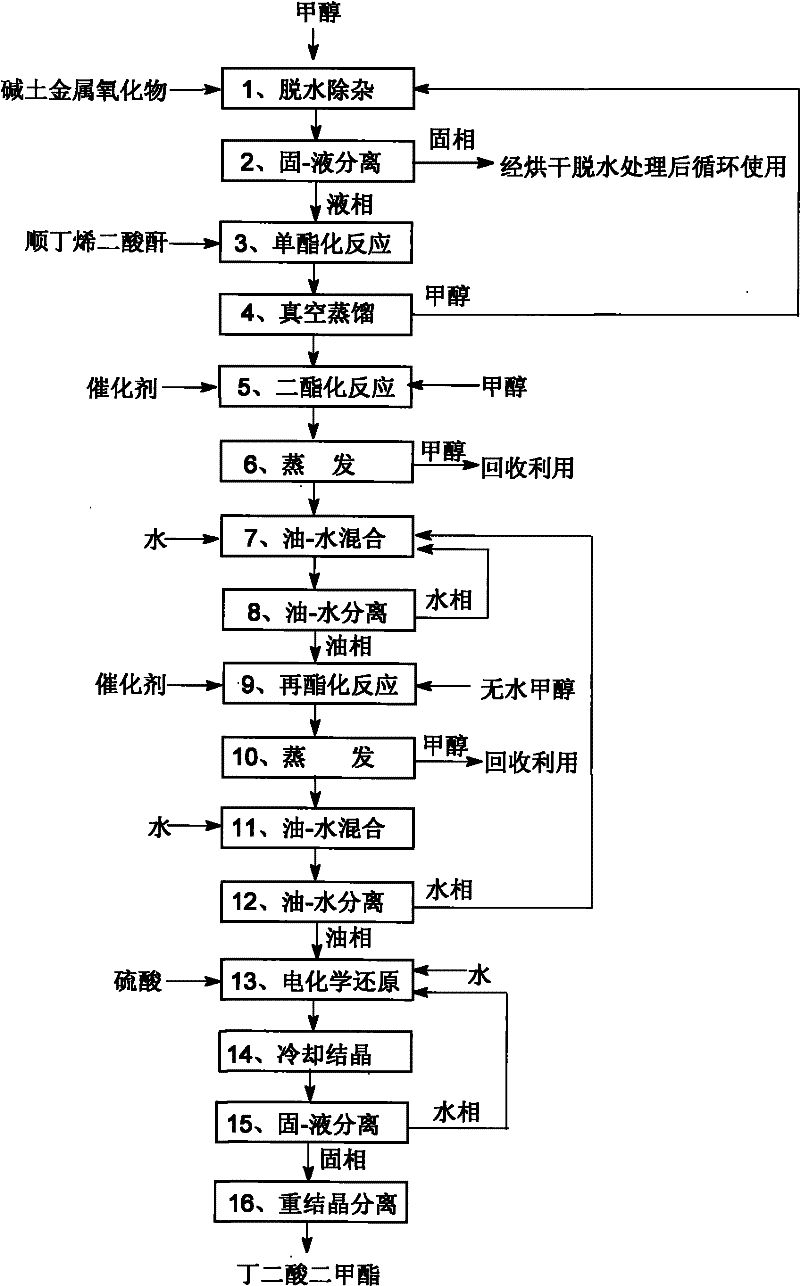

[0062] Main process equipment The chemical reactor for monomethyl esterification reaction, diesterification reaction and re-esterification reaction is a tank-type stirred chemical reactor, the solid-liquid separation device is a sedimentation type solid-liquid separation device, and the oil-water separation device is The sedimentation type oil-water separator, the electrochemical reduction reactor is an ordinary flat-plate electrochemical reactor, the anode chamber and the cathode chamber of the electrochemical reduction reactor are separated by an isolation membrane, and the isolation membrane is preferably a cationic membrane.

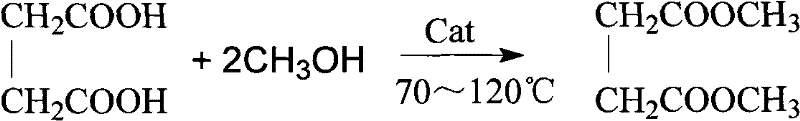

[0063] As shown in the figure, a method for preparing dimethyl succinate is to prepare dimethyl butyrate with maleic anhydride and methanol as raw materials, and the method steps are as follows:

[0064] (1) Dehydration and impurity removal: methanol is added to the dehydration and impurity removal equipment, and alkaline earth metal oxides are added ...

Embodiment 2

[0081] Main process equipment The chemical reactor for monomethyl ester reaction, diesterification reaction and re-esterification reaction is a tubular chemical reactor, the solid-liquid separation device is a filter type solid-liquid separation device, and the oil-water separation device is a centrifugal type The oil-water separator, the electrochemical reduction reactor is a three-dimensional electrochemical reactor, the anode chamber and the cathode chamber of the electrochemical reduction reactor are separated by an isolation membrane, and the isolation membrane is preferably a cationic membrane.

[0082] As shown in the figure, a kind of method for preparing dimethyl succinate is to prepare dimethyl succinate with maleic anhydride and methanol as raw material, and the method steps are as follows:

[0083] (1) Dehydration and impurity removal: methanol is added to the dehydration and impurity removal equipment, and alkaline earth metal oxides are added to mix evenly for deh...

Embodiment 3

[0100] Main process equipment The chemical reactor for monomethyl esterification reaction, diesterification reaction and re-esterification reaction is a static mixer, the solid-liquid separation device is a centrifugal solid-liquid separation device, and the oil-water separation device is a high-efficiency oil-water The separator and the electrochemical reduction reactor are ordinary flat-plate electrochemical reactors, and the anode chamber and the cathode chamber of the electrochemical reduction reactor are separated by an isolation membrane, and the isolation membrane is preferably a cationic membrane.

[0101] As shown in the figure, a kind of method for preparing dimethyl succinate is to prepare dimethyl succinate with maleic anhydride and methanol as raw material, and the method steps are as follows:

[0102] (1) Dehydration and impurity removal: Add methanol to the dehydration and impurity removal equipment, add alkaline earth metal oxides and mix evenly to perform dehyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com