Method for sulfidizing heavy metal waste and recovering valuable metals in heavy metal waste

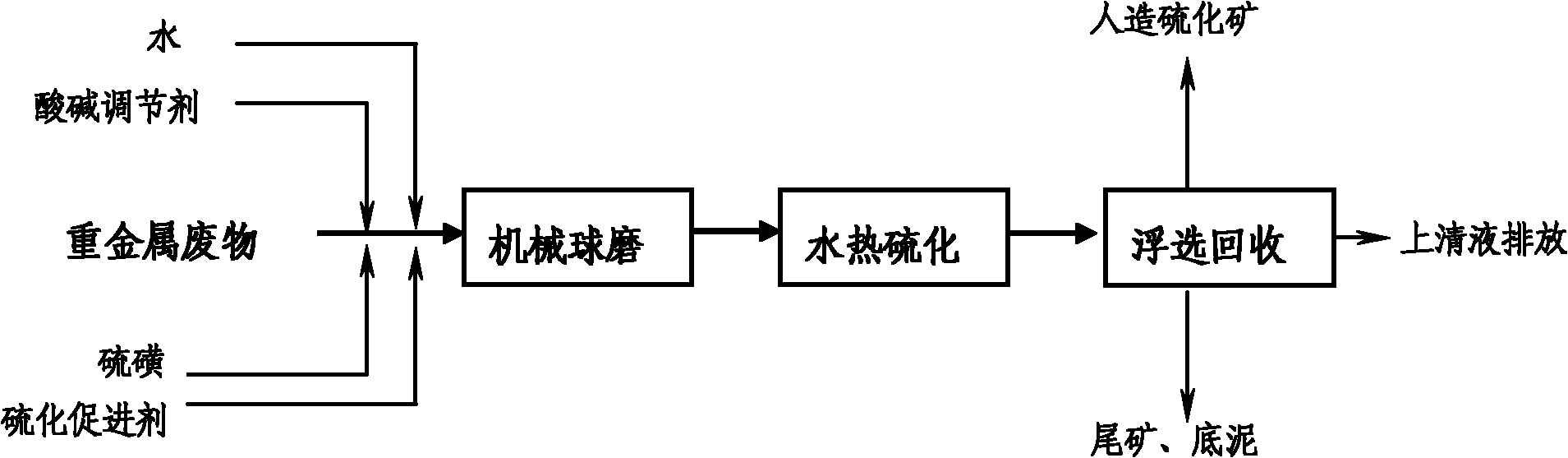

A technology of vulcanization treatment and valuable metals, which is applied in the field of environmental engineering, can solve the problems of secondary pollution of hydrogen sulfide and strong alkaline wastewater, low vulcanization rate of heavy metals, hindering popularization and use, etc., and achieve good hydrophobicity and buoyancy, The effect of complete vulcanization reaction and little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

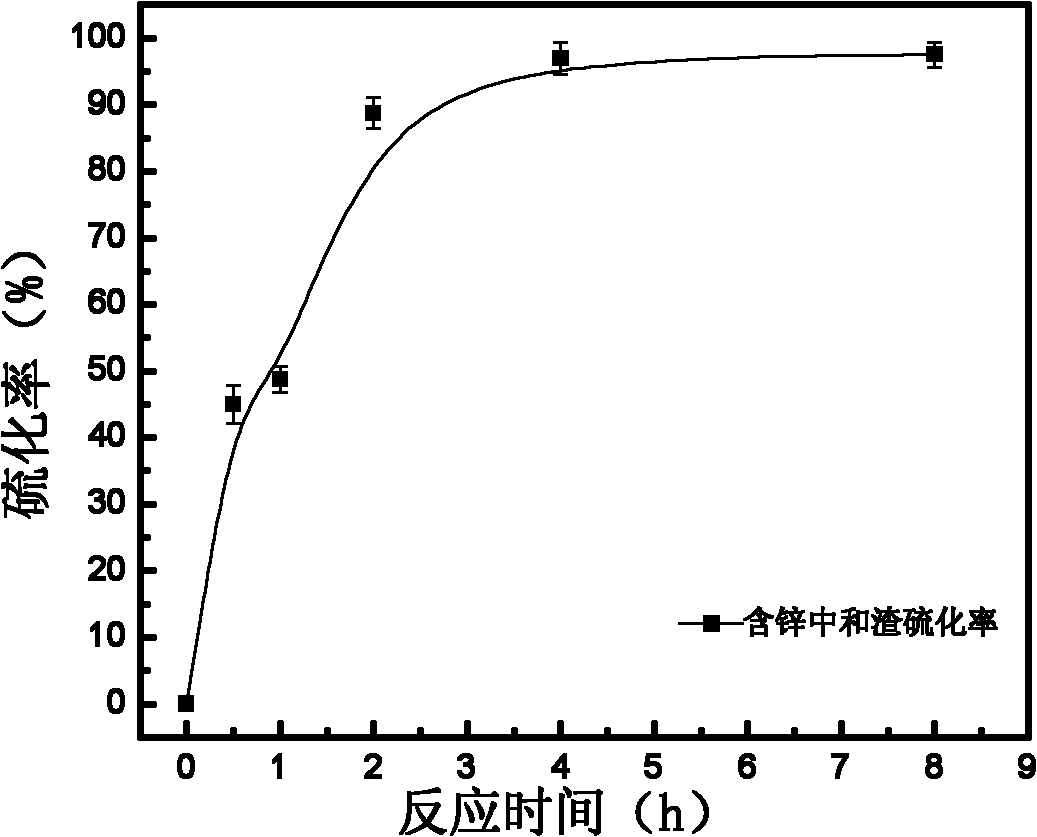

[0024] Sulfurization of zinc-containing waste residue in a smelter

[0025] Step 1: Grind the zinc-containing waste slag of a smelter to less than 5mm, and mix according to the ratio of Me:S=1:12, wherein Me represents the amount of all heavy metals in the waste slag on a dry basis, and S represents the added sulfur substance amount. Add water simultaneously, to guarantee that the liquid-solid ratio is 5: 1, then add vulcanization accelerator (the amount that adds is 5% of dry basis waste quality) and acid-base regulator, adjust pH value to be 12, after above-mentioned materials are mixed, put into the planetary ball mill.

[0026] Step 2: Turn on the ball mill, set the rotation speed to 500r / min, the ball milling time to 1 hour, and the ball-to-material ratio to 10:1. After the reaction stops, separate the material from the pellets and put the material into a high-temperature reactor.

[0027] Step 3: Open the autoclave after sealing it, set the temperature to 210°C, and th...

Embodiment 2

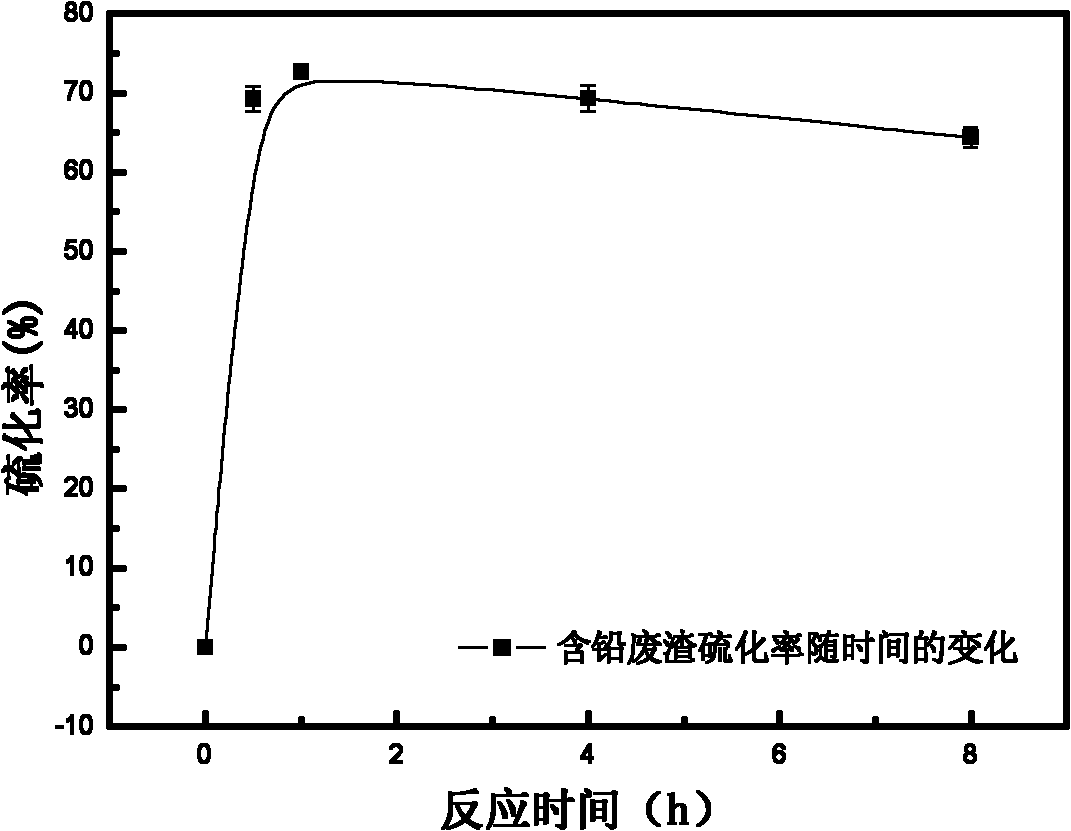

[0032] Sulfurization of lead-containing waste residue in a smelter

[0033] Step 1: Grind the sulfur tailings produced by a smelter to less than 5mm, and mix according to the ratio of Me:S=1:1.5, where Me represents the amount of all heavy metals in the waste slag on a unit dry basis, and S represents the added The amount of sulfurous substance. Add water and vulcanization accelerator NaOH at the same time (molar ratio NaOH:S=12:1), the amount of water added is preferably to ensure that the liquid-solid ratio is 5:1, and the above materials are mixed and put into a planetary ball mill.

[0034] Step 2: Turn on the ball mill, set the rotating speed to 500r / min, the ball milling time is 0-8 hours, the ball-to-material ratio is 10:1, and after the reaction stops, the material is separated from the pellets. Dry and grind the materials with different ball milling reaction times, carry out phase analysis, and calculate the change of the vulcanization rate with time ( image 3 ). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com