Fluorocarbon resin coating

A fluorocarbon resin and coating technology, applied in the direction of coating, etc., can solve the problems of affecting the effect of painting, inability to apply painted workpieces, shrinkage on the surface of the paint film, etc., to achieve the effect of reducing cleaning costs, easy cleaning, and avoiding shrinkage cavities

Active Publication Date: 2012-01-25

长春易浦汽车零部件有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But do not find that fluorocarbon resin coatings known in the art are widely used in coating workpieces at present. This is because in the production process of automobile coating, spray paint is sensitive to free low surface energy substances. The precipitation and exudation of substances will have a major impact on the paint film. If the free low surface energy substances accumulate in the paint spraying workshop for a long time, it will cause serious paint film drawbacks, that is, shrinkage cavities appear on the surface of the paint film, which will seriously affect the painting effect.

Existing fluorocarbon resin coatings contain free low surface energy substances, such as low molecular weight fluorocarbons or silicone oils, etc. Therefore, existing fluorocarbon coatings cannot be applied to coating workpieces

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

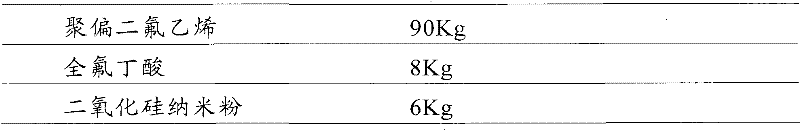

Embodiment 1

[0038] The composition of the fluorocarbon resin coating that this embodiment provides is:

[0039]

[0040]

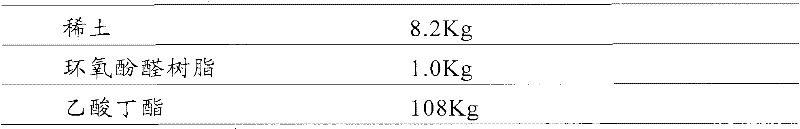

Embodiment 2

[0042] The composition of the fluorocarbon resin coating that this embodiment provides is:

[0043]

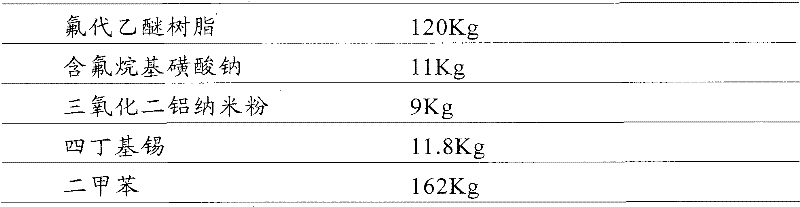

Embodiment 3

[0045] The composition of the fluorocarbon resin coating that this embodiment provides is:

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a fluorocarbon resin coating, which comprises the following components in percentage by weight: 20 to 70 percent of fluorocarbon resin of which the weight-average molecular weight is between 5,000 and 20,000, 1 to 7 percent of fluorine-containing compound or silicon-containing compound, 1 to 5 percent of inorganic nanometer-powder, 1.1 to 7.2 percent of drier, and the balance of organic solvent, wherein the fluorine-containing compound or the silicon-containing compound comprises one or more radicals of an epoxy group, an amino group, a hydroxyl group, a carboxyl group,a sulfonic acid group and an ester group. The fluorocarbon resin coating cannot generate free low surface energy substances in use; and when the fluorocarbon resin coating is coated on the surface ofa coating workpiece to form a coating layer, on the first hand, the coating workpiece is isolated from a painting environment to ensure that the coating workpiece can be cleaned easily and the cleaning cost is reduced, and on the other hand, the painting effect is not influenced to avoid shrinkage cavities on the surface of a paint film.

Description

technical field [0001] The invention relates to the field of coatings, in particular to a fluorocarbon resin coating. Background technique [0002] Paint is a chemical product made of resins and oils, with or without pigments. Applying the paint on the surface of the object can dry and form a film, which separates the surface of the object to be coated from the environmental medium, thereby protecting the object to be coated. Low surface energy coatings refer to coatings with a contact angle greater than 90 degrees when in contact with the substrate after coating. It is a type of surface engineering coating system that has developed rapidly in recent years. Low surface energy coatings mainly include silicone coatings, fluorocarbon resin coatings and silicone-fluorine coatings. Among them, coatings with fluorocarbon resin as the main film-forming substance are called fluorocarbon resin coatings, and the fluorocarbon chains in fluorocarbon polymers are short. , the chain ene...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D127/12C09D127/16C09D133/00C09D129/10C09D7/12

Inventor 董德文谢祯礼梁永久

Owner 长春易浦汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com