Preparation method for tert-butyl carbazate

A technology of carbazic acid and t-butyl ester, which is applied in the field of industrial preparation of tert-butyl carbazate, can solve the problems of unfavorable industrial use, low safety factor, skin irritation, etc., and achieves low cost, short reaction time, and method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

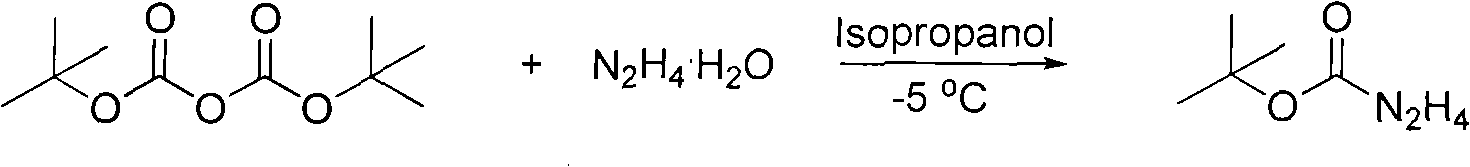

[0018] The preparation method of tert-butyl carbazate of the present invention comprises the steps:

[0019] In the first step, first add hydrazine hydrate and isopropanol into the reaction kettle, start stirring, and lower the temperature; 70% to 80%; the temperature of the material in the kettle drops to -5°C when stirring, the purity of hydrazine hydrate is greater than 98% (mass), and the purity of isopropanol is greater than 99% (mass).

[0020] In the second step, the BOC anhydride and isopropanol are transported to the high-position stirring drop tank, and stirred, and the uniformly stirred BOC anhydride and isopropanol mixture is slowly added dropwise to the hydrazine hydrate isopropyl alcohol in the reaction kettle in the first step In the alcohol solution; BOC anhydride accounts for 56-60% of the total weight of the feed, and isopropanol accounts for 40-44% of the total weight of the feed; the purity of BOC anhydride and the purity of isopropanol are greater than 99%...

Embodiment 1

[0026] Turn on the cooling system, extract 50 kg of hydrazine hydrate and add it to the 500-liter reactor, then add 128 kg of isopropanol to the 500-liter reactor, stir at low temperature for 1 hour, and control the temperature in the reactor at about -5°C. Transfer 100 kg of BOC anhydride and 72 kg of isopropanol to a high-level stirring drop tank, and slowly drop the uniformly stirred mixture into a 500-liter reactor. During the dropwise addition, the temperature of the reaction solution in the kettle should not exceed 0°C. The dropwise addition takes about 5 hours. After the dropwise addition, turn off the brine pump, stop the low-temperature cooling, and stir at room temperature for 12 hours. Isopropanol was distilled off. Add 280 kg of dichloromethane, add 10 kg of anhydrous sodium sulfate, and stir at room temperature for 2 hours. Sodium sulfate was filtered out, anhydrous sodium sulfate was washed with dichloromethane, and sodium sulfate was sucked dry. The dichloro...

Embodiment 2

[0028] Turn on the cooling system, extract 100 kg of hydrazine hydrate and add it to the 500-liter reactor, then add 128 kg of isopropanol to the 500-liter reactor, stir at low temperature for 1 hour, and control the temperature in the reactor at about -5°C. Transfer 100 kg of BOC anhydride and 72 kg of isopropanol to a high-level stirring drop tank, and slowly drop the uniformly stirred mixture into a 500-liter reactor. During the dropwise addition, the temperature of the reaction solution in the kettle should not exceed 0°C. The dropwise addition takes about 5 hours. After the dropwise addition, turn off the brine pump, stop the low-temperature cooling, and stir at room temperature for 24 hours. Isopropanol was distilled off. Add 280 kg of dichloromethane, add 10 kg of anhydrous sodium sulfate, and stir at room temperature for 2 hours. Sodium sulfate was filtered out, anhydrous sodium sulfate was washed with dichloromethane, and sodium sulfate was sucked dry. The dichlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com