Method for preparing nanometer silicon dioxide

A nano-silicon dioxide, silicon dioxide technology, applied in the directions of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of large modifiers, adverse effects on product performance, increased cost, etc., and achieves low drying temperature and high drying temperature. Practical value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

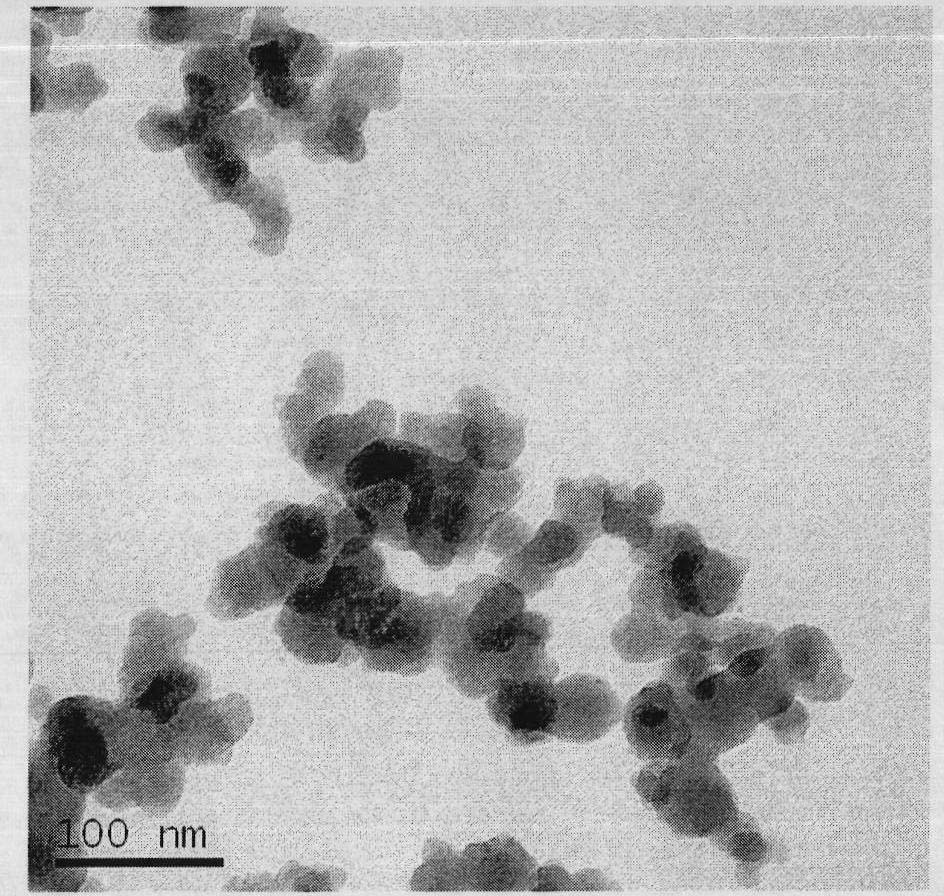

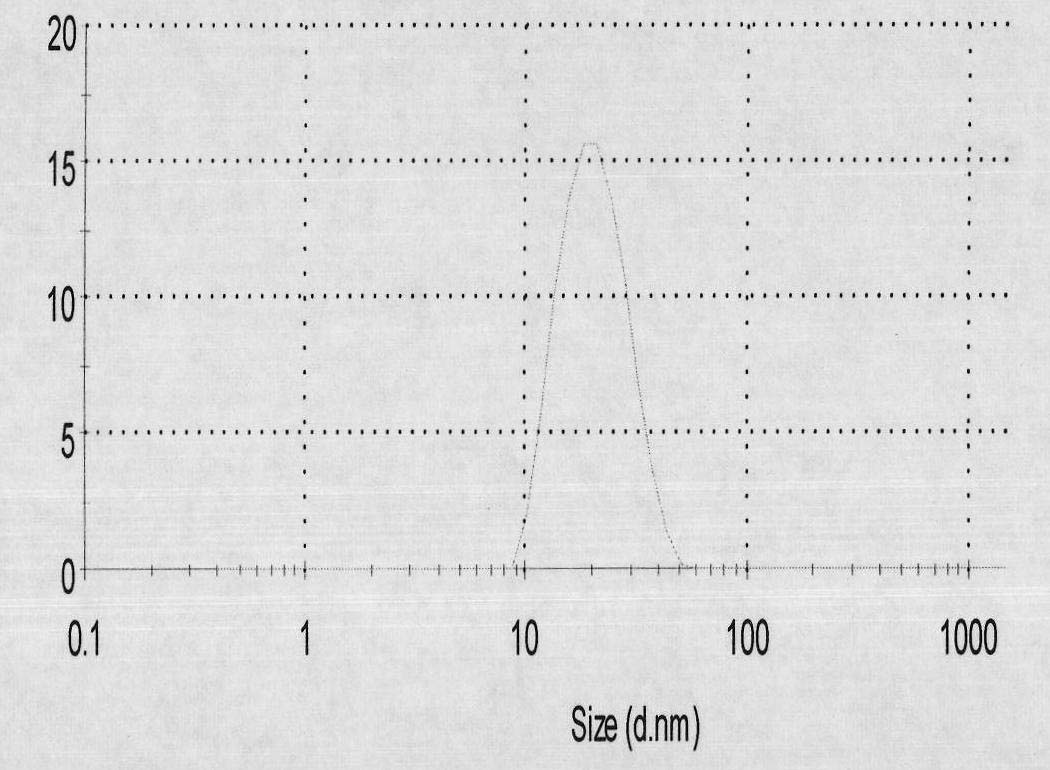

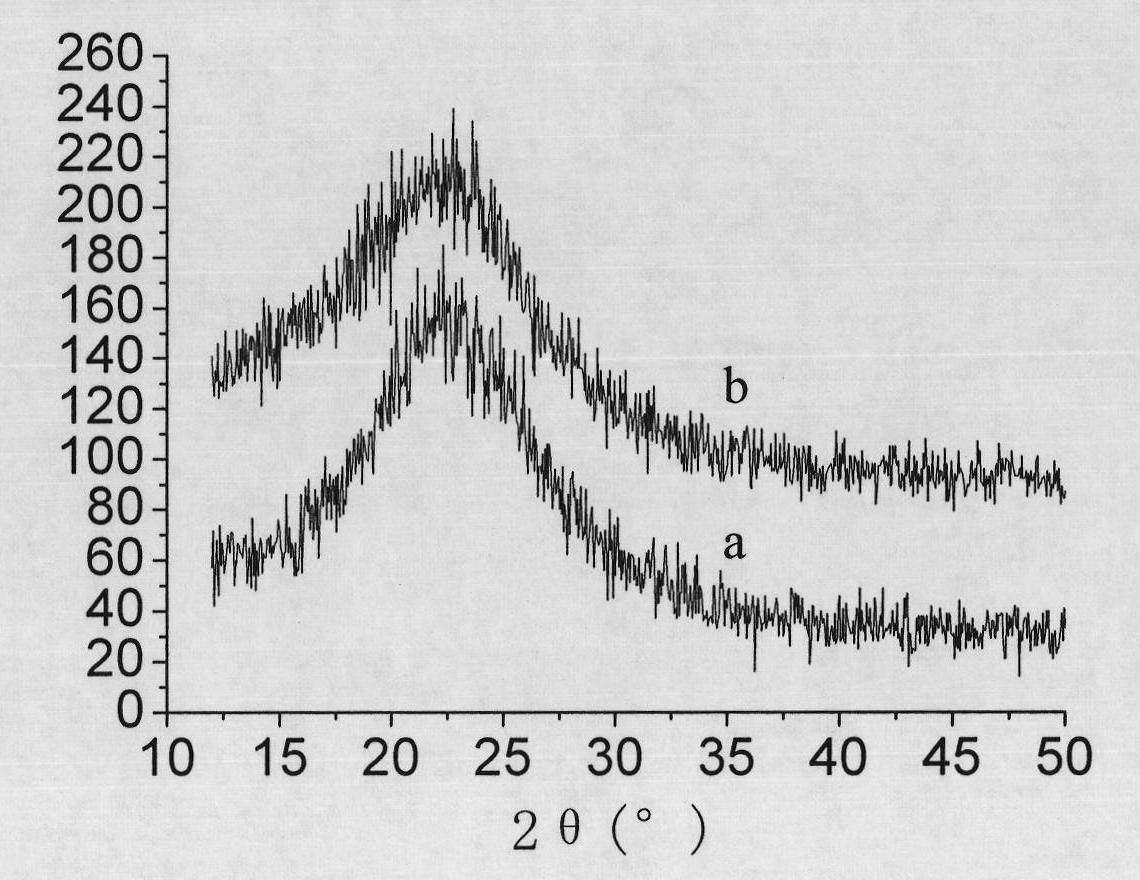

Embodiment 1

[0025] Dissolve 280g of sodium silicate in a mixture of 1600ml of deionized water and 400ml of absolute ethanol as solution A; a certain amount of 20% hydrochloric acid solution as solution B; 320ml of 20% sodium chloride solution as solution C; at room temperature Next, pour the prepared reaction solution into the barrel respectively, and feed the material into the self-made reaction device at a certain speed according to the parallel flow of four feeding pipes, and at the same time, feed gas into the reaction device through the inlet pipe (gas flow 4KPa) , high-speed stirring (6000r / min) and control the pH of the reaction system = 8 ~ 9, synthesize nano-SiO in a composite shear force field 2 . Continue stirring for 10 minutes after the simultaneous addition of the reaction solution, pour the milky white reaction solution into a beaker to settle, age for 24 hours, filter with suction, wash until there is no chloride ion, and then vacuum dry at 90°C for 24 hours to obtain whit...

Embodiment 2

[0027] On the basis of Example 1, 60 ml of 20% polyethylene glycol was added in the C liquid, and other conditions and implementation methods were the same as in Example 1. Preparation of Nano-SiO Modified by Surfactant Polyethylene Glycol 2 .

Embodiment 3

[0029] On the basis of Example 1, 15 g / L of hydrolyzed silane coupling agent KH570 was used as D liquid; at the same time, it was fed in parallel, and other conditions and implementation methods were the same as in Example 1. Preparation of Nano-SiO Modified by Coupling Agent 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com