Lanthanide-doped bismuth titanate film and preparation method thereof

A technology of lanthanide element and bismuth titanate is applied in the field of bismuth titanate thin film and its preparation, which can solve the problems of low orientation selectivity and unreachable, and achieve the effects of simple operation, low cost and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

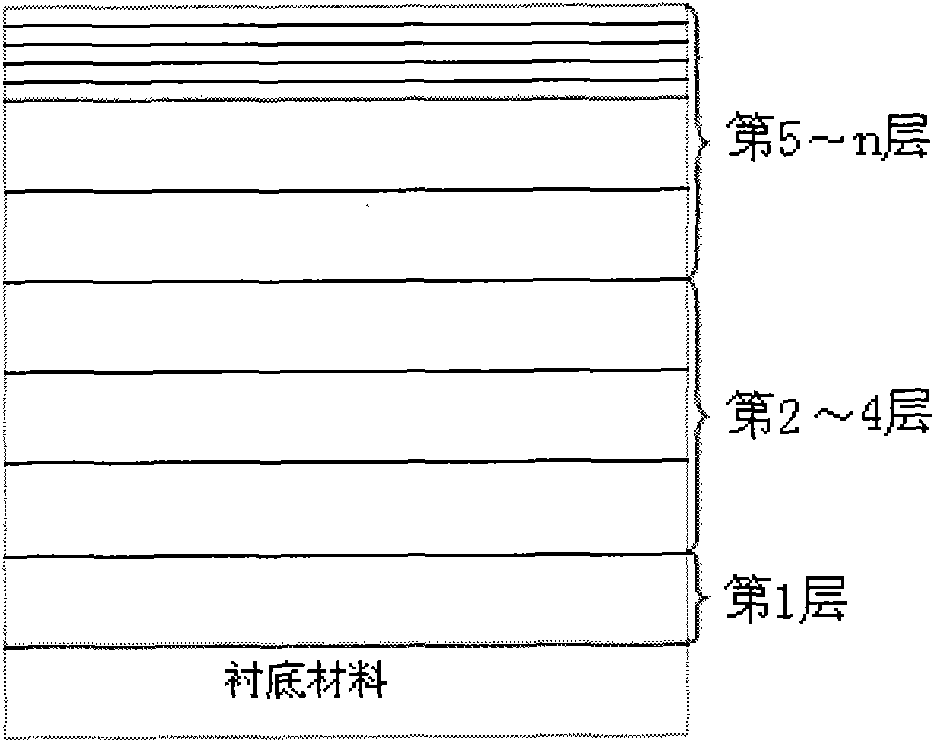

[0023] Neodymium-doped bismuth titanate Bi (4-x)(1+y) Nd x Ti 3 o 12 The composition of each layer of the film is Bi 3.15(1+y) Nd 0.85 Ti 3 o 12, that is, the doping molar amount of Nd is 0.85, the Bi in Nd-doped bismuth titanate is excessive, and y is the excess percentage of Bi by weight; y is 15% in the first layer of materials, and y in the second to fourth layers of materials y is 20%, and y is 25% in the fifth and above layers of materials, and the thickness of each layer of material is 50nm until the thickness of the film meets the requirements required for practical applications.

[0024] The preparation method of this thin film comprises the following steps:

[0025] (1) Weigh bismuth nitrate, neodymium nitrate and tetrabutyl titanate with a molar ratio of 3.62:0.85:3 respectively, and dissolve bismuth nitrate and neodymium nitrate in a mixed solution of 20ml ethylene glycol and glacial acetic acid. Add tetrabutyl titanate, stir evenly, and then add acetylacet...

Embodiment 2

[0030] Neodymium-doped bismuth titanate Bi (4-x)(1+y) Nd x Ti 3 o 12 The composition of each layer of the film is Bi 3.5(1+y) Nd 0.05 Ti 3 o 12 , that is, the doping molar amount of Nd is 0.5, the Bi in Nd-doped bismuth titanate is excessive, and y is the excess percentage of Bi by weight; y is 10% in the first layer of materials, and y in the second to fourth layers of materials y is 15%, and y is 20% in the fifth layer and above, and the thickness of each layer of material is 40nm until the film thickness reaches the requirement.

[0031] The preparation method of this thin film comprises the following steps:

[0032] (1) Prepare Bi respectively according to the local method described in embodiment 1 3.85 Nd 0.5 Ti 3 o 12 、 Bi 4.03 Nd 0.5 Ti 3 o 12 and Bi 4.20 Nd 0.5 Ti 3 o 12 The concentrations of the three precursor solutions are all 0.2mol / L.

[0033] (2) adopt the same method as example 1 to deposit the precursor solution on the substrate material LaN...

Embodiment 3

[0037] Lanthanum-doped bismuth titanate Bi (4-x)(1+y) La x Ti 3 o 12 In the film, the composition of each layer of material is Bi 3.25(1+y) La 0.75 Ti 3 o 12 , that is, the doping molar amount of La is 0.75, the Bi in the lanthanum-doped bismuth titanate must be excessive, and y is the excess percentage of Bi by weight; y is 12% in the first layer of materials, and y in the second to fourth layers of materials y is 17%, and y is 22% in the fifth layer and more than five layers of materials, and the thickness of each layer of material is 60nm.

[0038] The preparation method of this thin film comprises the following steps:

[0039] (1) Prepare Bi respectively according to the local method described in embodiment 1 3.64 La 0.75 Ti 3 o 12 、 Bi 3.80 La 0.75 Ti 3 o 12 and Bi 3.97 La 0.75 Ti 3 o 12 Three kinds of precursor solutions, the concentration of the solution is 0.1mol / L;

[0040] (2) adopt the same method as example 1 to deposit the precursor solution on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com