Phosphoric acid tail gas electric demister

A technology of electrostatic defogging and exhaust gas, applied in the field of phosphorus chemical technology and environmental protection, can solve pollution and other problems, achieve the effect of solving environmental pollution, compact arrangement structure, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

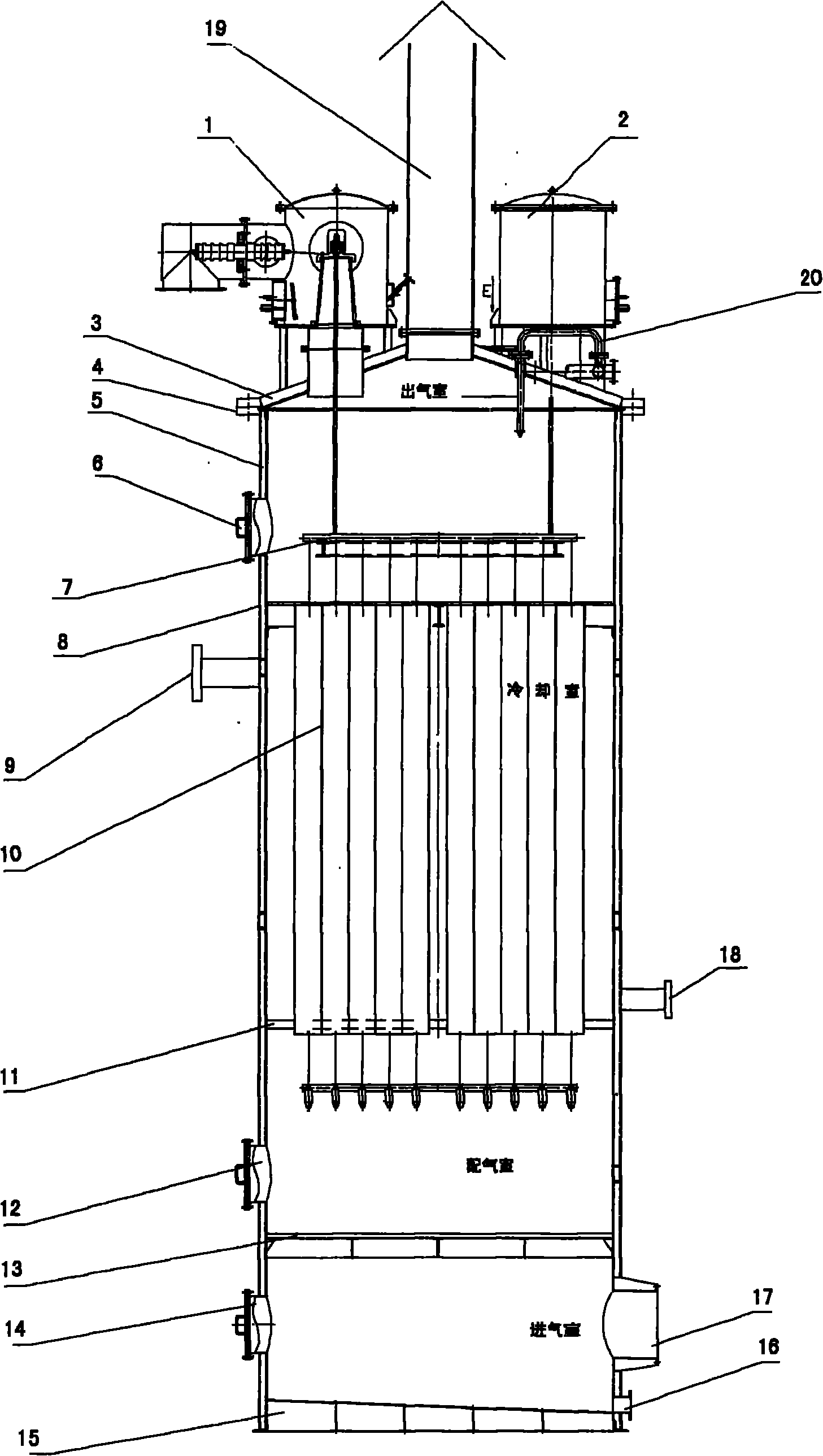

[0023] Phosphoric acid tail gas electric defogging and purification equipment, the high-voltage constant current DC power supply lead insulation box 1 is fixed on the top cover 3, and is connected with the corona electrode device 7; the non-lead insulation box 2 is fixedly connected on the top cover 3; the top cover 3 It is connected with the shell 5 by the flange 4; the first flower plate 8 and the second flower plate 11 are respectively welded with the anode electrostatic precipitation tube 10 and the shell 5; the gas distribution plate 13 is located between the manhole 12 of the gas distribution chamber and the manhole 14 of the air intake chamber The room is welded with the shell 4; the inclined bottom plate 15 is located at the bottom of the shell 5 and welded with the shell 5; the flushing device 20 is fixed on the top cover 3; the water outlet 9 and the water inlet 18 are respectively located at the bottom of the first flower plate 8 and the second flower plate 11 The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com