Water-soluble silymarin and preparation method thereof

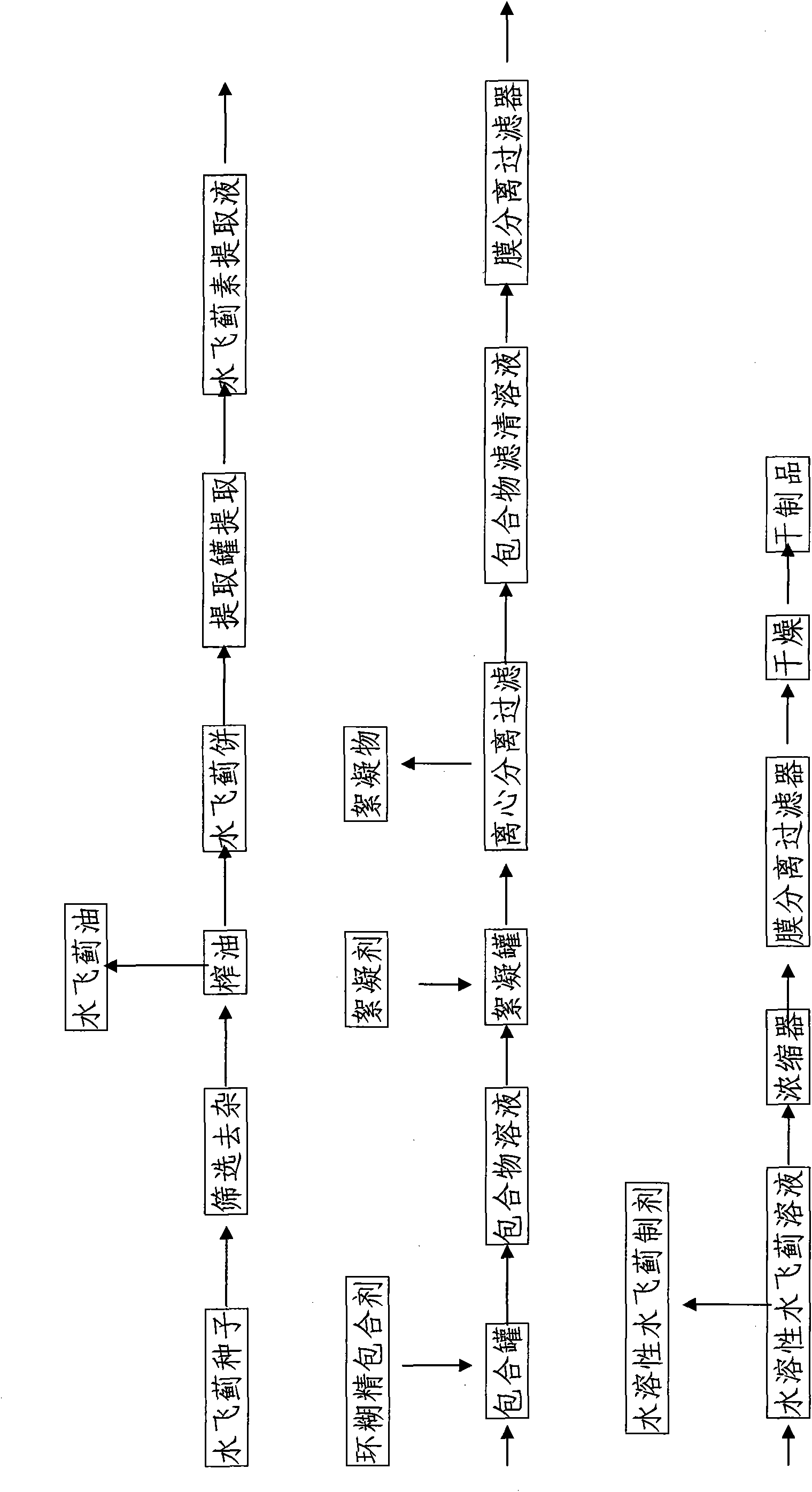

A silymarin and water-soluble technology, which is applied in the direction of pharmaceutical formulations, organic active ingredients, and medical preparations containing active ingredients, can solve the problem of fat-soluble silymarin solvent residues, low solubility and bioavailability of active ingredients, and difficulty in making Intravenous injections and other issues, to achieve the effect of improving bioavailability, improving production efficiency, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The milk thistle seeds are first screened to remove impurities, and then the oil is squeezed out with a screw oil press to form milk thistle cakes. The milk thistle oil is for sale; the milk thistle cakes are in the shape of round cakes, and the outer diameter of the round cakes is 110mm, and the thickness is controlled Between 1.5mm±0.2mm; milk thistle cake for later use.

[0025] Put 500 kg of silymarin cake after oil removal into the extraction tank, and put into the extraction tank 4000 kg of lye ethanol with a weight ratio of 1:8; the lye ethanol is thrown into the ethanol solution with solid NaOH and mixed Forming, the weight percent concentration of ethanol solution is 30%, promptly contains the NaOH of 30% ethanol solution 97kg and 3kg in every 100kg alkali water ethanol. The pH of the alkaline water ethanol is 8.3. Heat the mixture of alkaline water ethanol and milk thistle cake in the extraction tank to 80° C., keep the temperature at a constant temperature f...

Embodiment 2

[0030] After the milk thistle seeds are screened to remove impurities, the oil is squeezed out with a mechanical oil press, and the milk thistle oil is sold; the squeezed milk thistle cake is preliminarily crushed for later use.

[0031] Put the milk thistle cake after the oil is squeezed into the extraction tank, and fill the extraction tank with the alkali water ethanol in the ratio of the milk thistle cake to the alkali water ethanol weight ratio of 1:7. Alkaline ethanol is mixed by ethanol solution and solid NaOH, and the weight percentage of its ethanol solution is 25%, contains 25% ethanol solution 96kg, NaOH4kg in every 100kg alkali ethanol, alkali water ethanol PH=8.5. Heat the mixture of alkaline water ethanol and milk thistle cake in the extraction tank to 85° C., keep the temperature at a constant temperature for 1.5 hours, and then extract twice continuously to obtain milk thistle extract.

[0032]The milk thistle extract is transported to the clathrate tank, and t...

Embodiment 3

[0036] After the milk thistle seeds are screened to remove impurities, the oil is squeezed out with a mechanical oil press, and the milk thistle oil is sold; the squeezed milk thistle cake is preliminarily crushed for later use.

[0037] Put the milk thistle cake after the oil is squeezed into the extraction tank, and fill the extraction tank with the alkali water ethanol in the ratio of the milk thistle cake to the alkali water ethanol weight ratio of 1:9. Alkaline ethanol is mixed by ethanol solution and solid NaOH, and the weight percent of its ethanol solution is 35%, contains 35% ethanol solution 98kg, NaOH 2kg in every 100kg alkali ethanol, alkali water ethanol PH=8. Heat the mixture of alkaline water ethanol and milk thistle cake in the extraction tank to 75° C., keep the temperature at a constant temperature for 2.5 hours, and extract continuously 4 times to obtain milk thistle extract.

[0038] The milk thistle extract is transported to the clathrate tank, and the cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Dimensions | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com