Integrated chip type oxygen sensor and manufacturing method thereof

An oxygen sensor and integrated chip technology, which is applied in the field of integrated chips for zirconia sensors, can solve the problems of many processes, complex structure, etc., and achieves the effects of simple preparation process, small size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

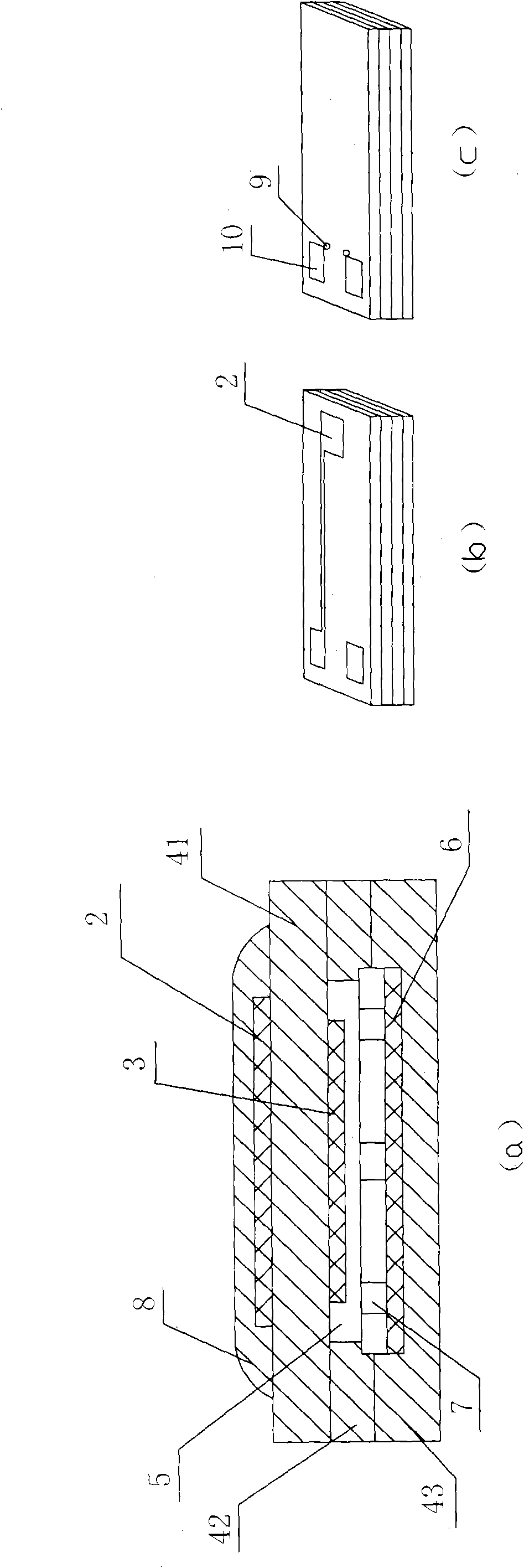

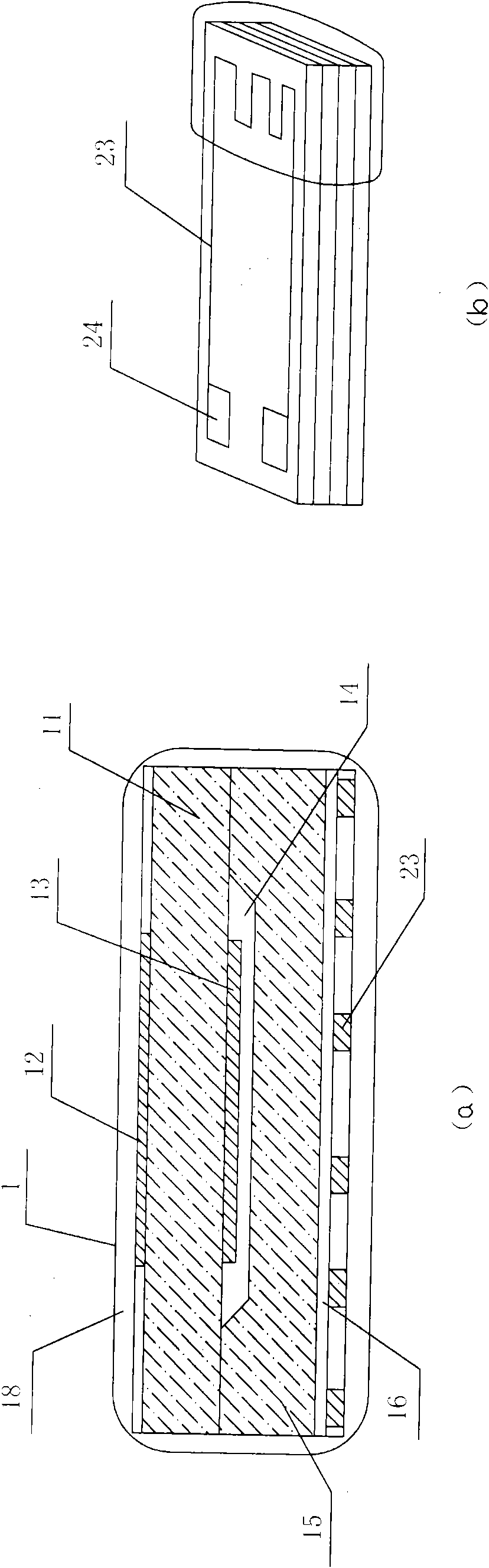

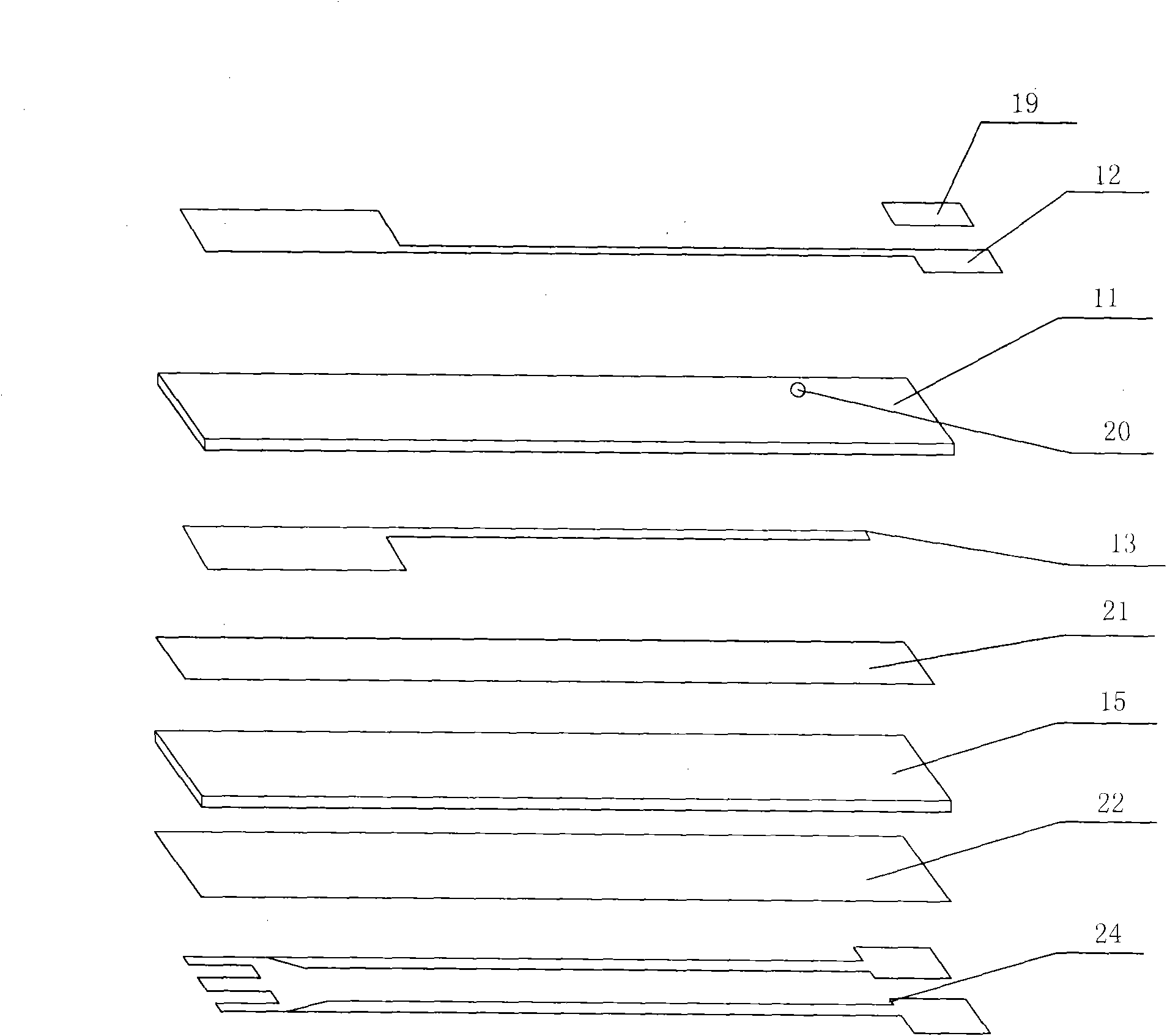

[0037] Combination and decomposition below image 3 The fabrication process of the oxygen sensor of the present invention is described in detail.

[0038] In the first step, the zirconia powder of 5% mole yttrium oxide is mixed with PVB, terpineol and dibutyl phthalate (DBP) with a mass ratio of 80:10:5:5 to prepare a slurry by ball milling, and then pass Tape casting with double-knife-edge technology, after natural drying, make a zirconia green strip, and then punch it into a substrate green body, that is, the upper zirconia substrate 11; then mix the electrode slurry containing 70% to 90% platinum powder and The conductive paste is printed on the inner and outer surfaces of the upper zirconia substrate 11 to form the measuring electrode 12 and the reference electrode 13; the electrodes on the inner surface are connected to the inner electrode connecting piece on the outer surface through the electrode connection through hole 20 punched and formed at the end of the upper zirc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com