System and method for using sintering waste heat to generate electricity

A waste heat power generation and sintering machine technology, which is applied in waste heat treatment, machinery/engine, lighting and heating equipment, etc., can solve the problems of unstable operation of waste heat power generation, low sensible heat utilization rate and high operating cost, and reduce equipment investment. , The effect of reducing equipment investment and operating costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

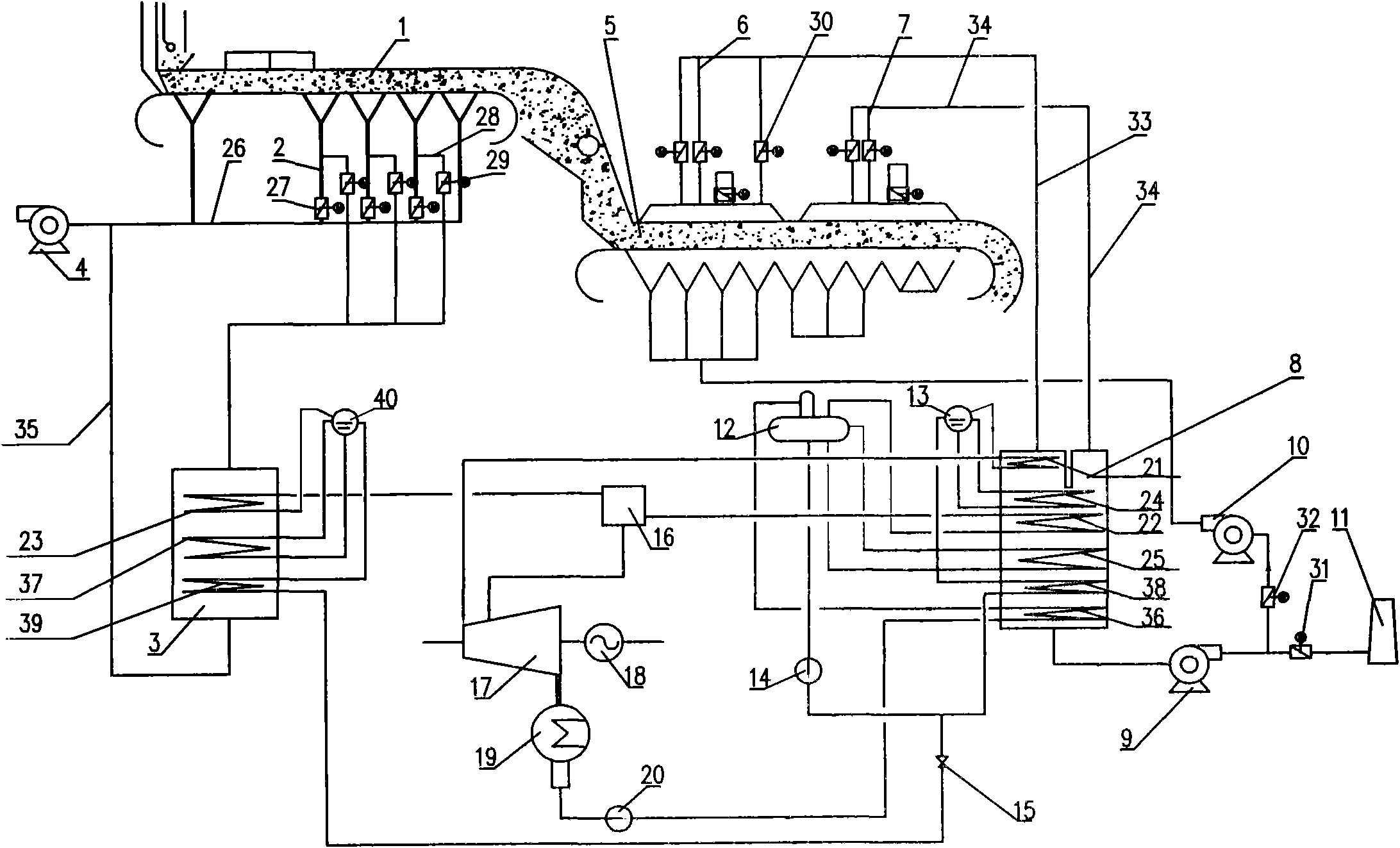

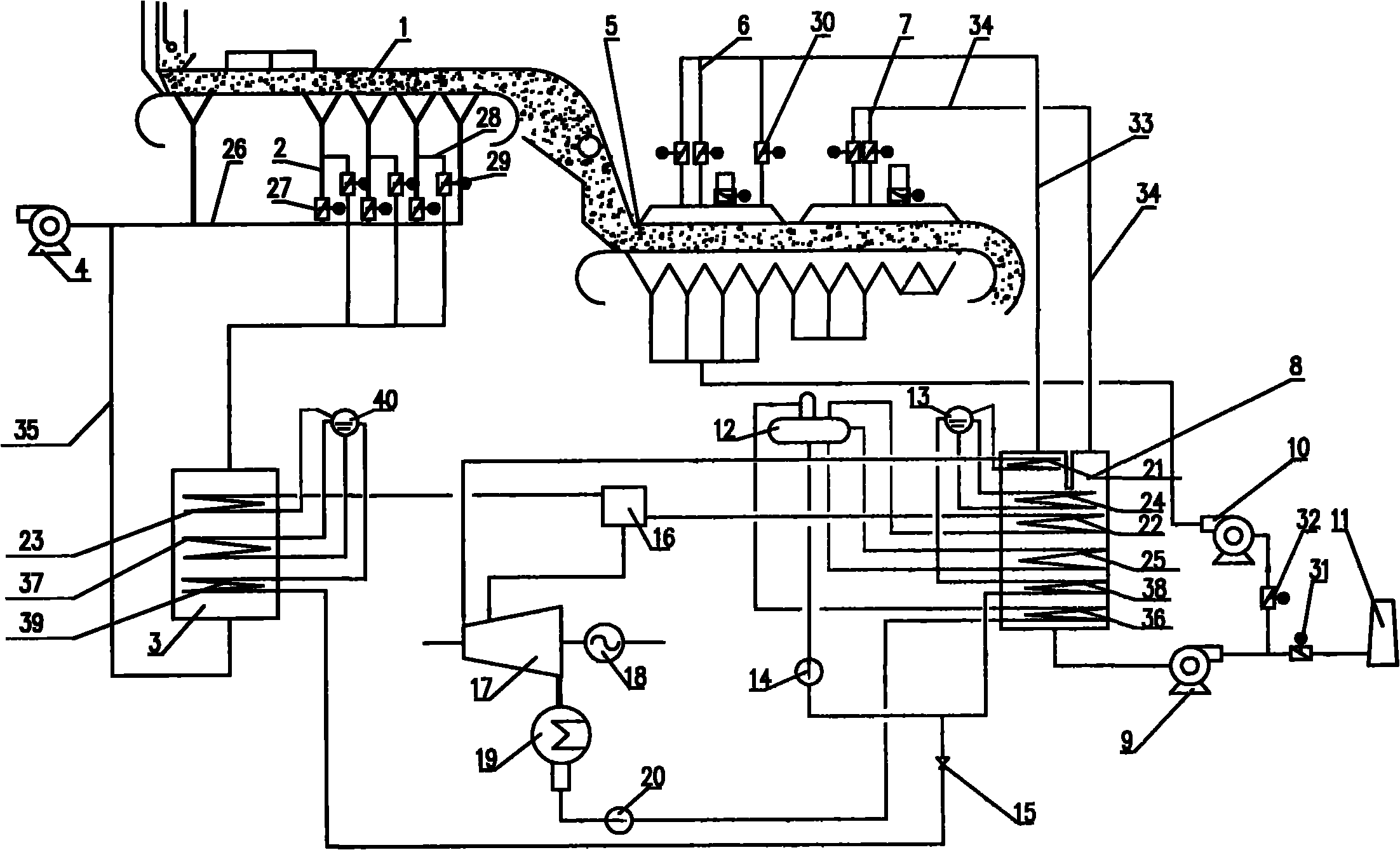

[0041] A sintering waste heat power generation system, such as figure 1 As shown, including sintering machine hot flue gas system, hot waste gas waste heat utilization system and sintering waste heat power generation thermal system;

[0042] The hot flue gas system of the sintering machine is as follows: a hot flue gas outlet pipe 2 is provided in each of the bellows at the bottom of the sintering machine 1, and the other end of the hot flue gas outlet pipe 2 communicates with the hot flue gas manifold 26 at the tail. Each hot flue gas outlet pipe 2 is provided with a hot flue gas outlet pipe valve 27 at one end close to the hot flue gas manifold 26 at the tail, and a main exhaust fan 4 is arranged at one end of the hot flue gas manifold 26 at the tail, counting down from the tail of the sintering machine Starting from the second hot flue gas outlet pipe 2, hot flue gas br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com