Chemical treating method for melt polycondensation high polymer old material regeneration

A technology of melt polycondensation and chemical treatment, which is applied in the field of chemical fiber and plastic processing, and can solve the problems of irreversible quality degradation, raw material quality uniformity that cannot reach the high quality and continuity of industrial equipment, and achieve the goal of reducing demand and oil resources Consumption, the realization of circular economy, and the effect of stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

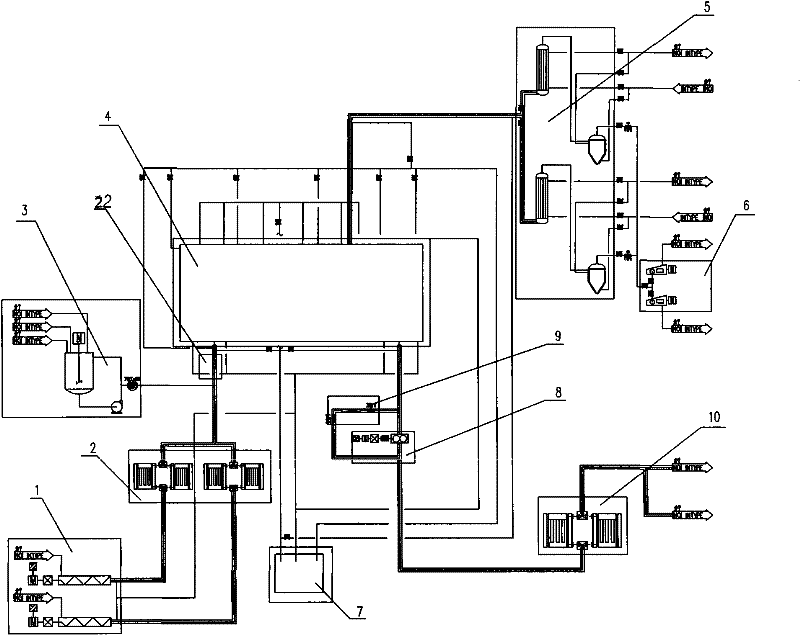

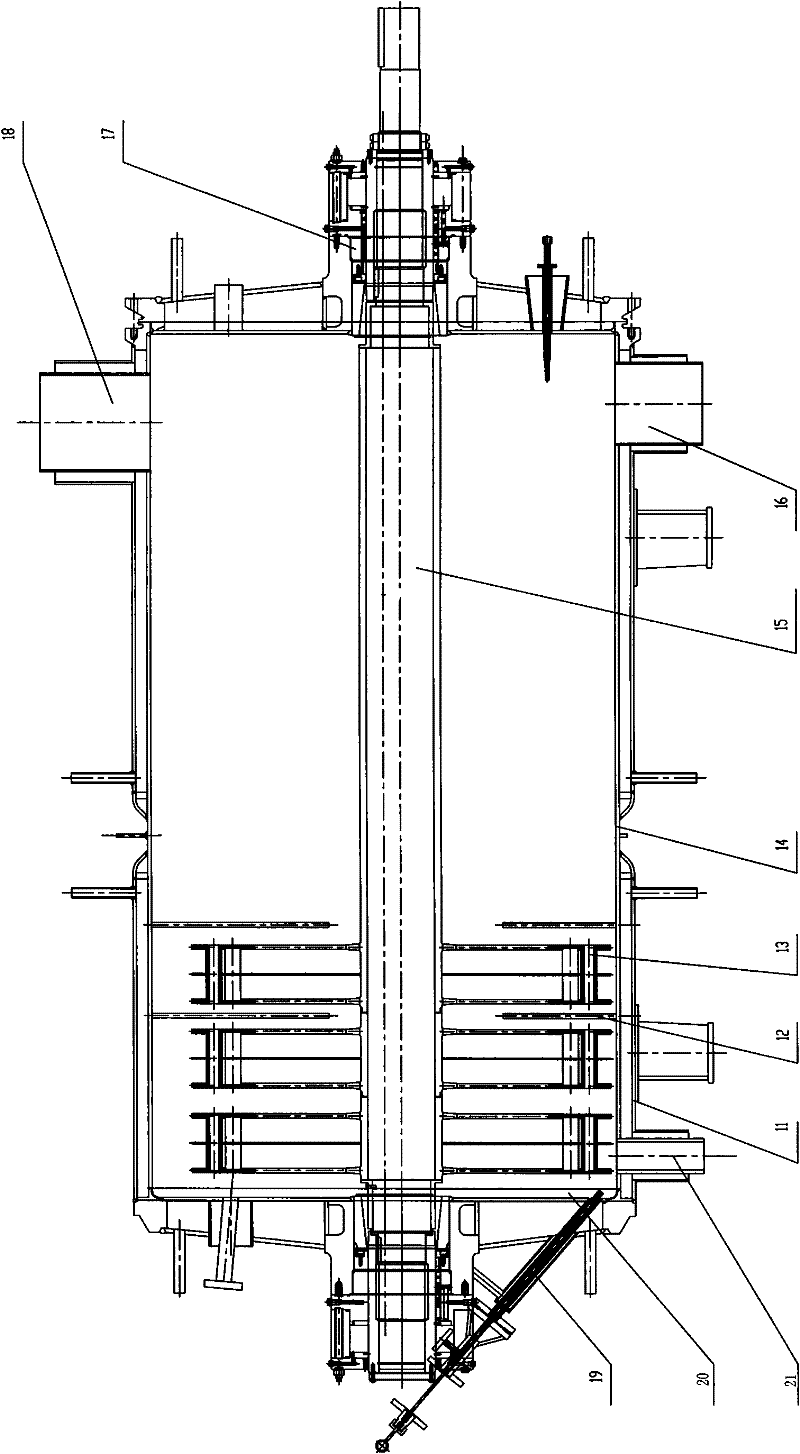

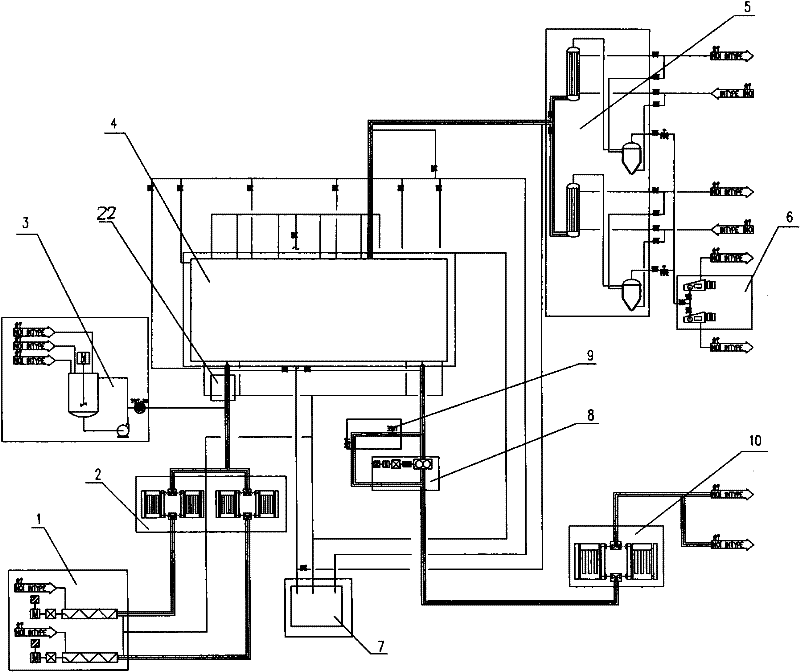

[0024] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the reclaimed material of the present invention is melted into a melt by ordinary deep groove single screw, and then the mechanical impurities and solid impurities in the melt are filtered through a filter to obtain a relatively pure melt, and then homogenized and repolymerized into an integrated horizontal Alcoholysis, homogenization, impurity removal, small molecule removal, and repolymerization are carried out in the type reactor, so that the molecular structure of recycled materials can be readjusted to meet the product requirements of different uses.

[0025] The recovered raw material is melted into a melt through the ordinary deep groove single screw 1, and then the mechanical impurities and solid impurities in the raw material are filtered out through the filter 2 to obtain a relatively pure melt. The quality of the melt at this time is not goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com