Nano-level iron adsorbent for efficient dephosphorization

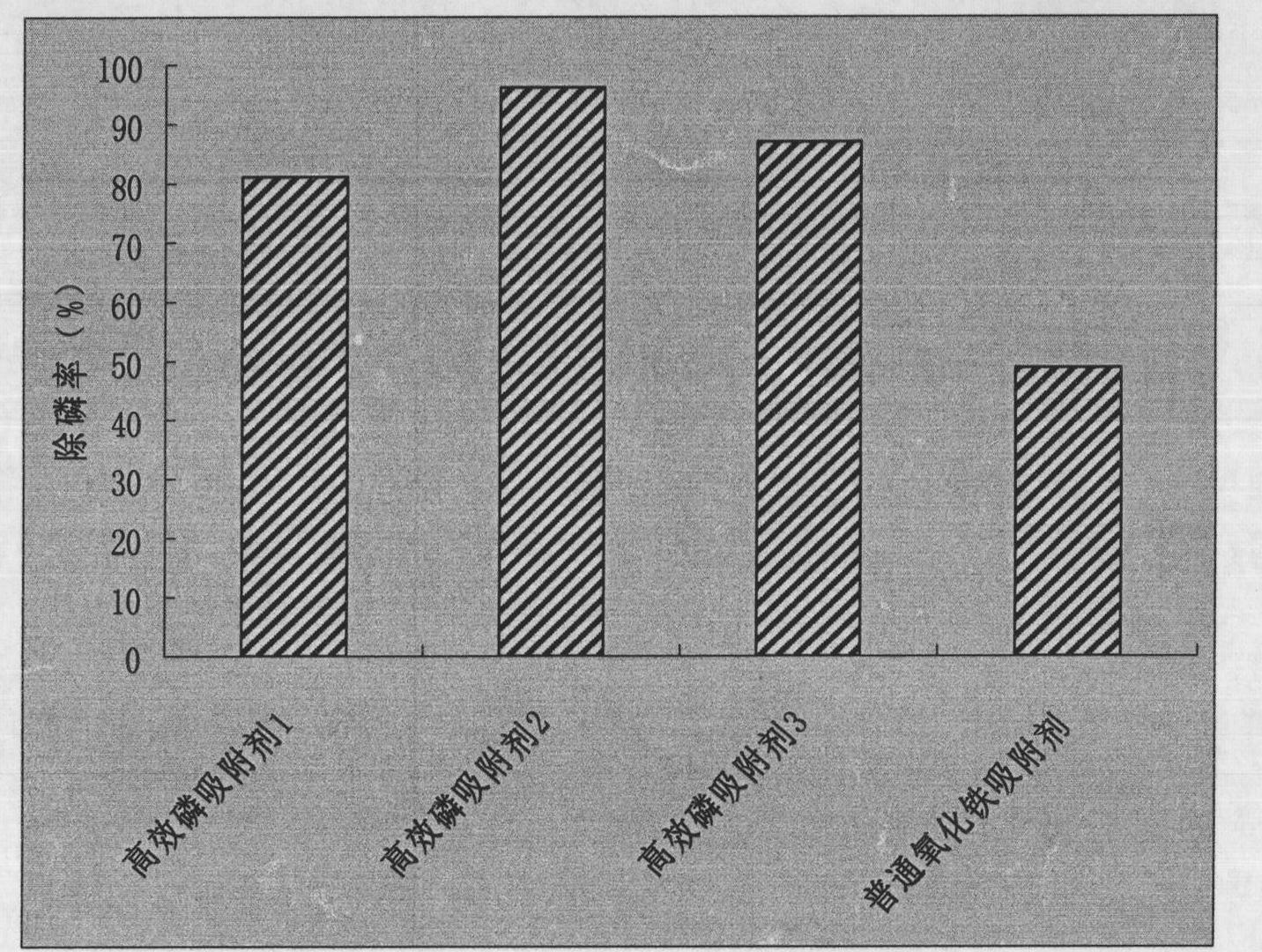

An adsorbent, nano-scale technology, applied in the field of water treatment, can solve the problems of high preparation conditions, toxic biological risks, etc., and achieve the effects of good dispersion effect, rapid and effective recovery, and strong phosphorus adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the preparation of efficient phosphorus adsorbent

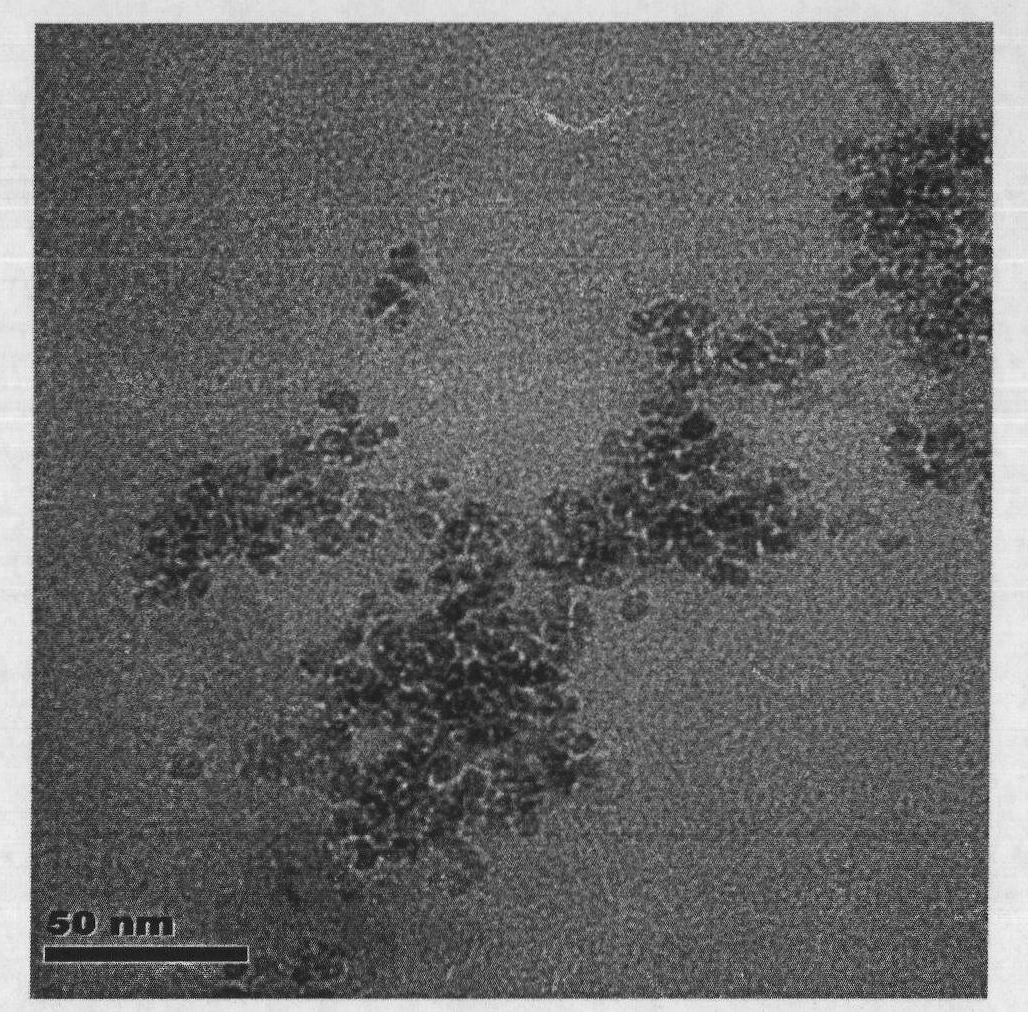

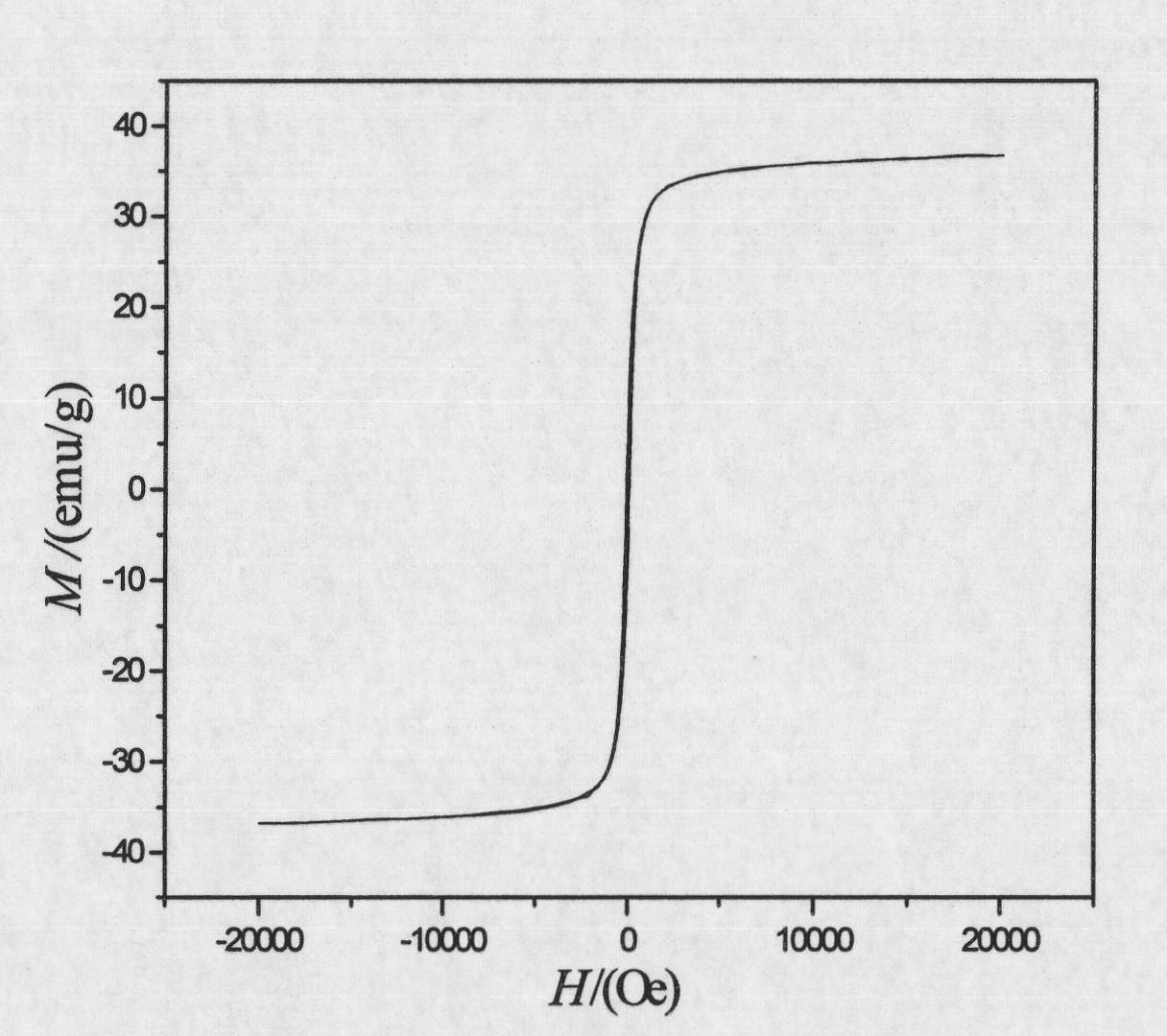

[0015] The stirring intensity is 1000s -1 Next, 100ml 0.1mol / L FeCl 2 4H 2 O solution was slowly poured into 100ml 1w / v% starch solution. Stir continuously for 30min, so that Fe 2+ Fully complexed with starch. Slowly add 0.1 mol / L NaOH solution dropwise to the solution until the pH>11, and continue to stir for 1 h to complete the reaction. After the reaction, the solid-liquid separation is carried out by using a magnet, and the adsorbent is repeatedly washed to neutrality with deionized water to remove excess electrolyte. Use after drying and grinding. The particle size is 10nm, and the saturation magnetization is 26.49emu / g.

Embodiment 2

[0016] The preparation of embodiment 2 efficient phosphorus adsorbent

[0017] The stirring intensity is 1000s -1 Next, 100ml 0.1mol / L FeCl 2 4H 2 The O solution was slowly poured into 100ml of 0.2w / v% starch solution. Stir continuously for 30min, so that Fe 2+ Fully complexed with starch. Slowly add 0.1 mol / L NaOH solution dropwise to the solution until the pH>11, and continue stirring for 1 h to complete the reaction. After the reaction, use a magnet for solid-liquid separation, and repeatedly rinse with deionized water until neutral to remove excess electrolyte. Dry and grind for later use. The particle size is 50nm, and the saturation magnetization is 26.78emu / g.

Embodiment 3

[0018] The preparation of embodiment 3 efficient phosphorus adsorbent

[0019] The stirring intensity is 1000s -1 Next, 100ml 0.1mol / L FeCl 2 4H 2 The O solution was slowly poured into 100ml of 0.02w / v% starch solution. Stir continuously for 30min, so that Fe 2+ Fully complexed with starch. Slowly add 0.1 mol / L NaOH solution dropwise to the solution until the pH>11, and continue to stir for 1 h to complete the reaction. After the reaction, use a magnet for solid-liquid separation, and repeatedly rinse with deionized water until neutral to remove excess electrolyte. Dry and grind for later use. The particle size is about 56nm, and the saturation magnetization is 36.18emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com