Antisludging agent for preventing deposition of Sr/Ba scale

A technology of scale inhibitor and strontium scale, which is applied in the field of chemicals used in the petroleum industry, can solve the problems of low scale prevention efficiency and low efficiency, and achieve the effect of prolonging the pump inspection period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the weight percent of each component of the antiscalant that prevents barium strontium scale deposition is:

[0051] 1. Dodecylamino ethyl phosphate (industrial product): 8.5%;

[0052] 2. Tetradecylaminoethyl phosphate (industrial product): 8.9%;

[0053] 3. Disodium salt of ethylenediaminetetraacetic acid (industrial product): 6.5%;

[0054] 4. Tetrasodium ethylenediamine tetrapropionate (industrial product): 2.5%;

[0055] 5. Ethylenediamine tetramethylene phosphonic acid (industrial product): 3.6%;

[0056] 6. Vitamin A (industrial product): 0.06%;

[0057] 7. Vitamin C (industrial product): 0.07%;

[0058] 8. Potassium iodide (industrial product): 0.006%;

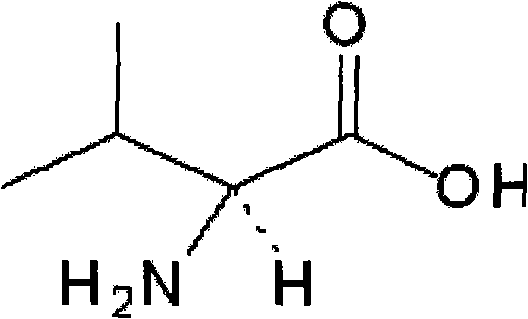

[0059] 9. α-amino-3-methylbutyric acid (industrial product): 0.0005%;

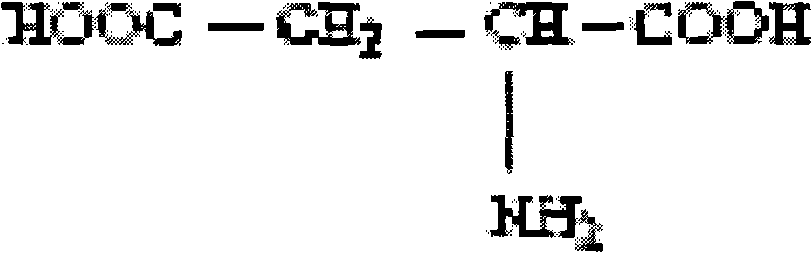

[0060] 10. Aspartic acid (industrial product): 0.0005%;

[0061] 11. Water: 69.863%.

[0062] Its preparation method is:

[0063] First, add dodecylaminoethyl phosphate and tetradecylaminoethyl phosphate into the ename...

Embodiment 2

[0065] Embodiment 2: the weight percent of each component of the antiscalant that prevents barium strontium scale deposition is:

[0066] 1. Dodecylamino ethyl phosphate (industrial product): 9%;

[0067] 2. Tetradecylamino ethyl phosphate (industrial product): 8.5%;

[0068] 3. Disodium salt of ethylenediaminetetraacetic acid (industrial product): 6.2%;

[0069]4. Tetrasodium ethylenediamine tetrapropionate (industrial product): 2.7%;

[0070] 5. Ethylenediaminetetramethylenephosphonic acid (industrial product): 3.9%;

[0071] 6. Vitamin A (industrial product): 0.05%;

[0072] 7. Vitamin C (industrial product): 0.05%;

[0073] 8. Potassium iodide (industrial product): 0.005%;

[0074] 9. α-amino-3-methylbutyric acid (industrial product): 0.0006%;

[0075] 10. Aspartic acid (industrial product): 0.0007%;

[0076] 11. The remainder is water; the sum of the weight percentages of each component is 100% (water is 69.5937%).

[0077] The preparation method of embodiment 2 i...

Embodiment 3

[0079] Embodiment 3: the weight percent of each component of the antiscalant that prevents barium strontium scale deposition is:

[0080] 1. Dodecylamino ethyl phosphate (industrial product): 9.6%;

[0081] 2. Tetradecylamino ethyl phosphate (industrial product): 8%;

[0082] 3. Disodium salt of ethylenediaminetetraacetic acid (industrial product): 6%;

[0083] 4. Tetrasodium ethylenediamine tetrapropionate (industrial product): 2.8%;

[0084] 5. Ethylenediaminetetramethylenephosphonic acid (industrial product): 4.1%;

[0085] 6. Vitamin A (industrial product): 0.07%;

[0086] 7. Vitamin C (industrial product): 0.08%;

[0087] 8. Potassium iodide (industrial product): 0.008%;

[0088] 9. α-amino-3-methylbutyric acid (industrial product): 0.0007%;

[0089] 10. Aspartic acid (industrial product): 0.0008%;

[0090] 11. Water is 69.3485%.

[0091] The preparation method of embodiment 3 is identical with embodiment 1.

[0092] Effect: When the amount of antiscalant to prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com