Direct ground driving gear of screw pump

A driving device and screw pump technology, applied in pumps, pump control, machines/engines, etc., can solve the problems of screw pump speed adjustment difficulties, low operating safety factor, high maintenance costs, etc., to reduce daily maintenance costs and avoid safety accidents , The effect of facilitating production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

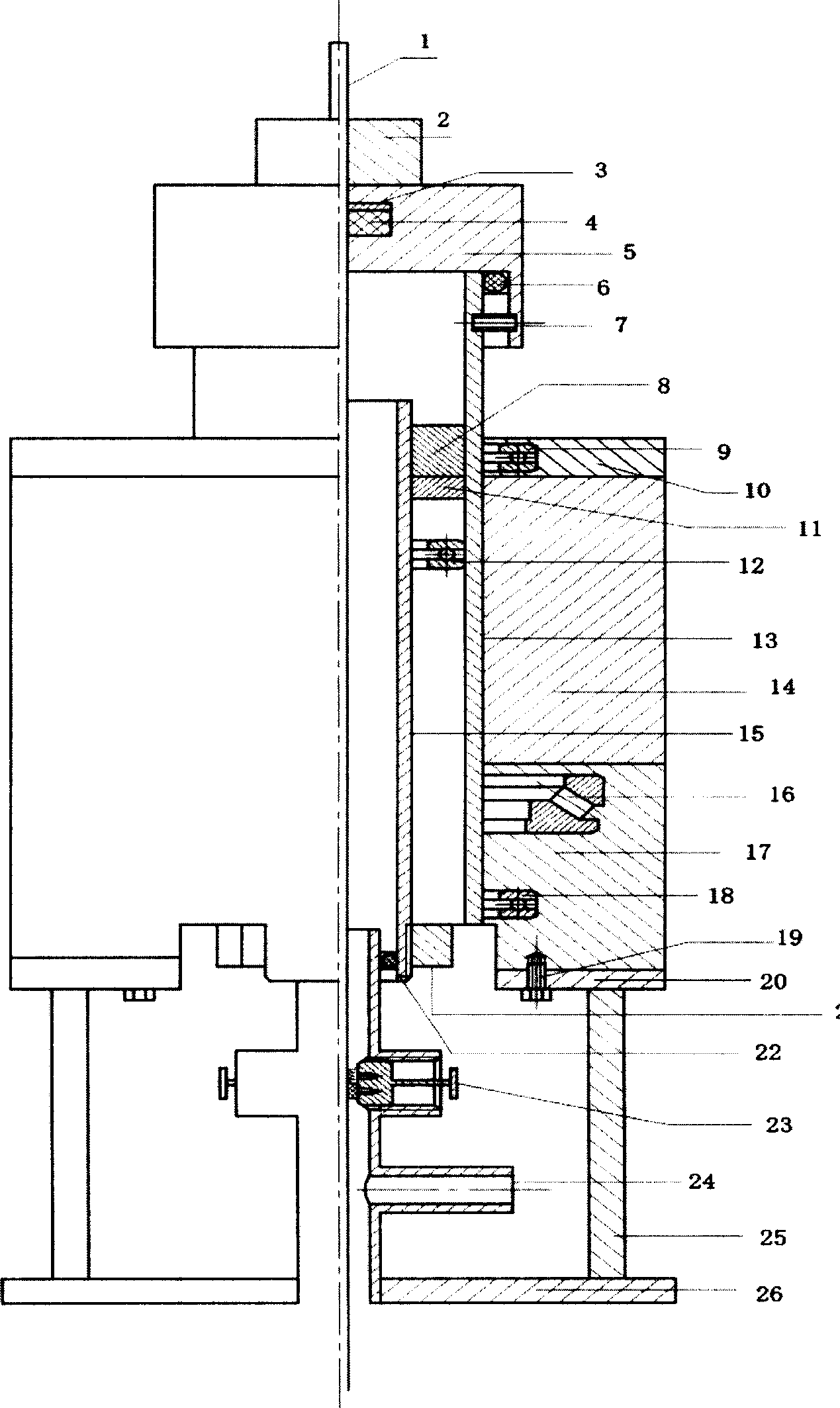

[0011] The present invention will be further described below in conjunction with accompanying drawing:

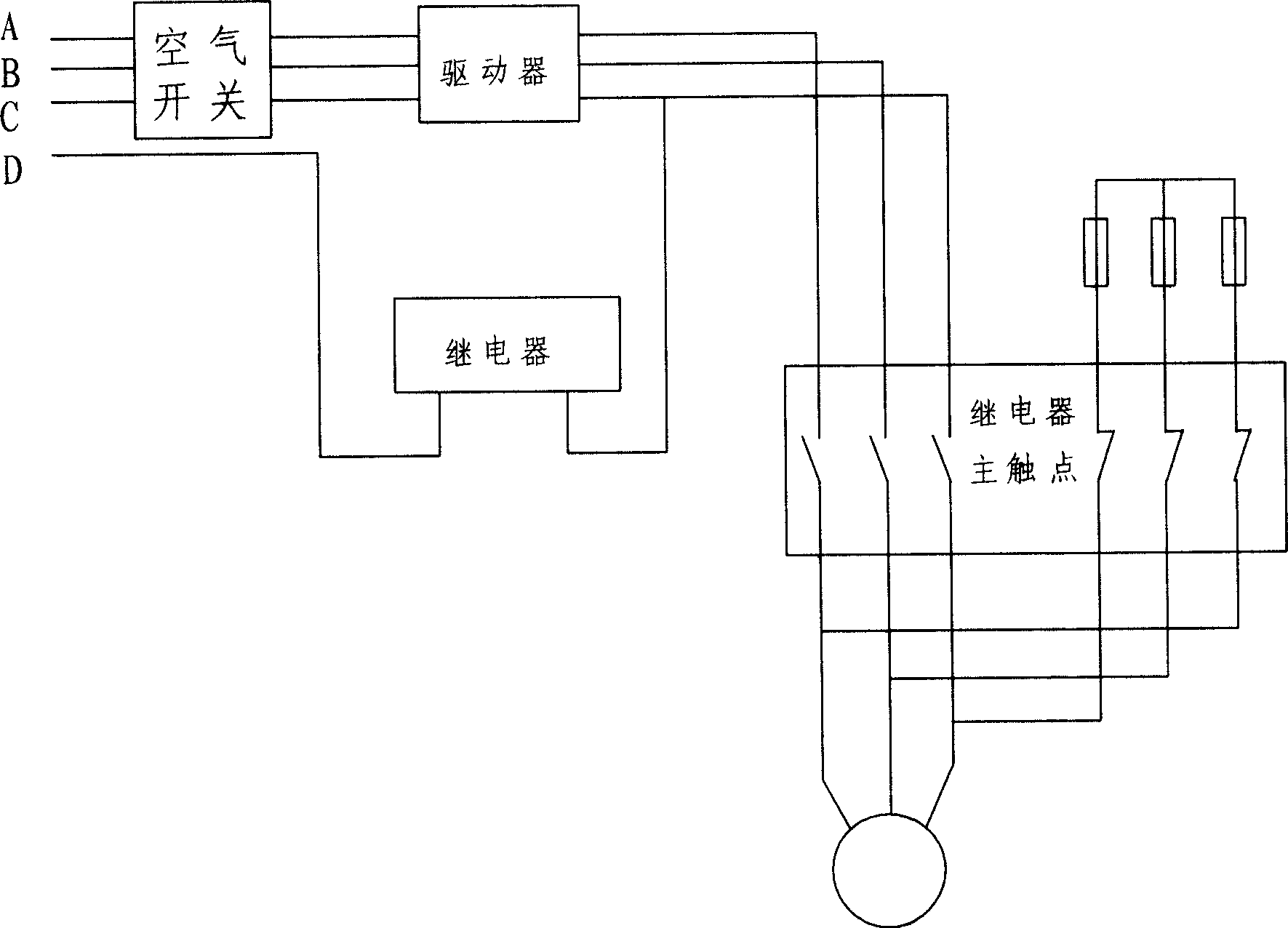

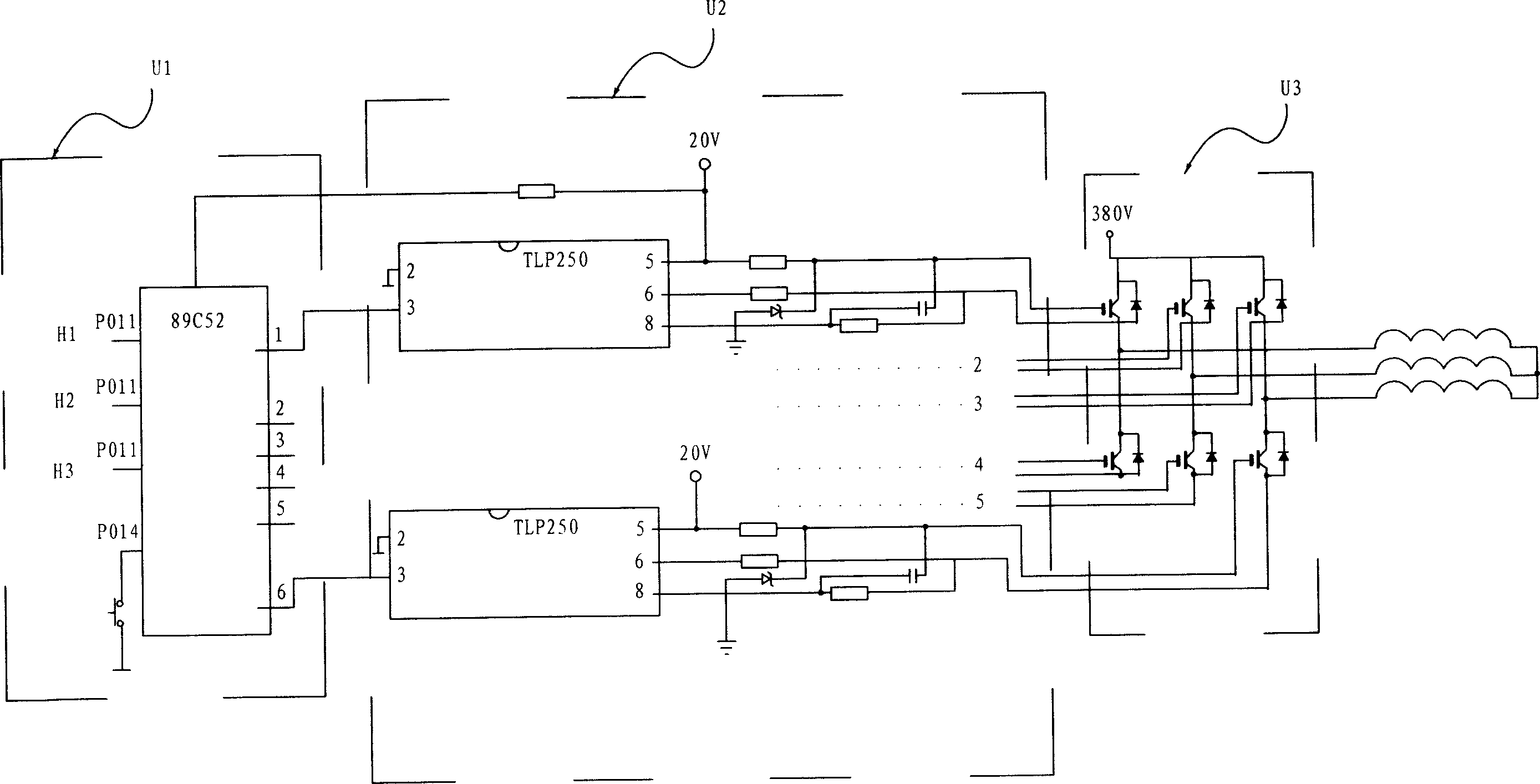

[0012] The purpose of the present invention is to develop a ground direct drive device for screw pumps used in oil fields. When installing, the screw pump sucker rod passes through the hollow motor shaft, and the hollow shaft power motor directly drives the screw pump sucker rod to run, and the screw pump The axial bearing device and mechanical seal device of the pump wellhead are designed in the end cover of the motor and the hollow shaft to realize the integration of axial bearing, mechanical seal and power motor. At the same time, electromagnetic braking technology is used to solve the reverse braking of the screw pump. .

[0013] Based on the above purpose, design according to the following steps:

[0014] One is to cancel the reducer and belt used for conventional screw pump transmission, the screw pump sucker rod directly passes through the hollow shaft of the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com