Special protector and method for speed reducer of downhole electric submersible progressing cavity pump

A technology of reducer and screw pump, which is applied in pumps, pump components, earthwork drilling, etc., can solve problems such as failure to popularize and apply, downhole reducer failure, poor lubrication, etc., to increase effective production days, reduce operating costs, The effect of prolonging the pump inspection period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

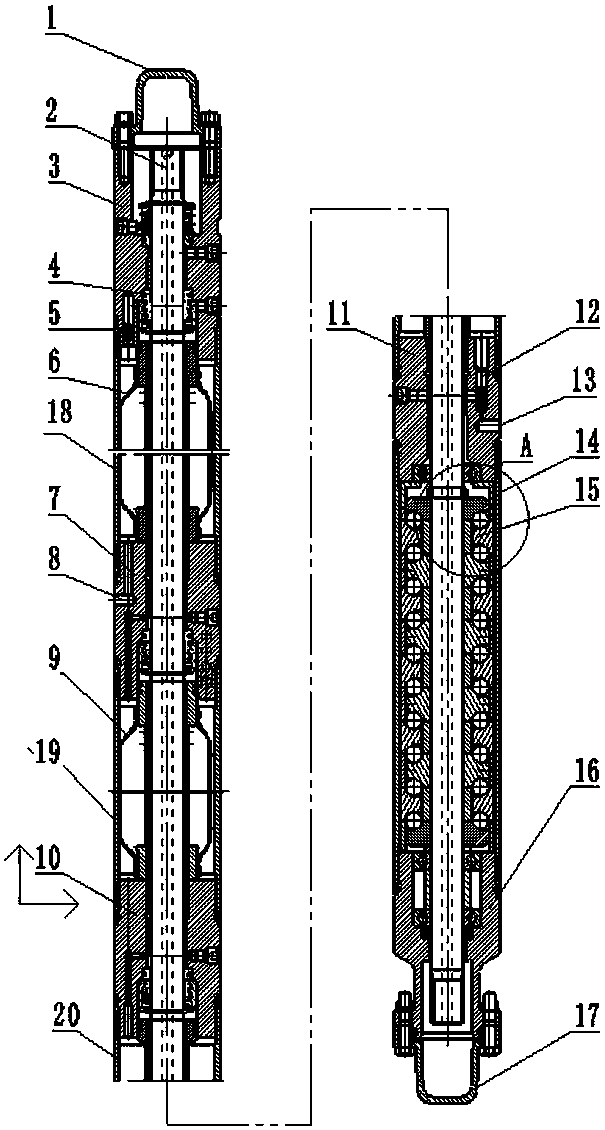

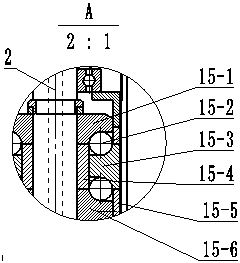

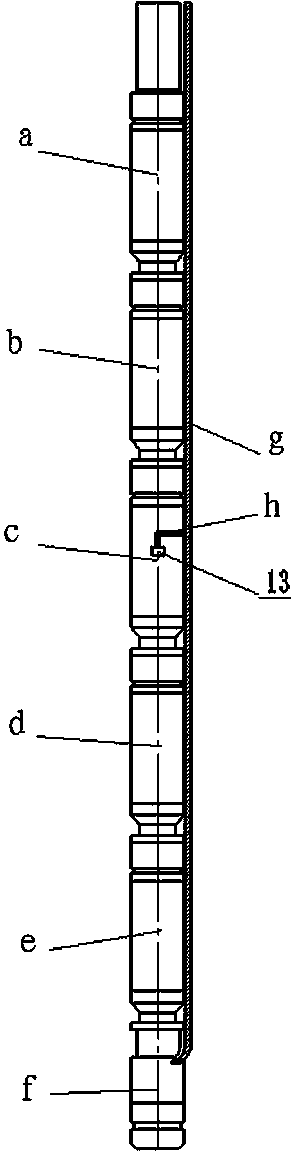

[0026] combined with Figure 1-3 , to further describe the present invention:

[0027] A special protector for downhole electric submersible screw pump reducer mentioned in the present invention, including an upper transport cap 1, a hollow main shaft 2, a head assembly 3, a mechanical seal assembly 4, an oil drain valve assembly 5, and an upper capsule 6 , upper guide body 7, breathing hole 8, lower capsule 9, middle guide body 10, lower guide body assembly 11, high-pressure check valve assembly 12, oil filling joint hole 13, lower housing 14, thrust bearing group 15, base Assembly 16, lower transportation cap 17, upper casing 18, middle casing 19 and connecting pipe 20, the upper transportation cap 1 is movably connected with the head assembly 3, and the hollow main shaft 2 is fixed inside the head assembly 3, And the bottom of the head assembly 3 cooperates with the hollow main shaft 2 through the mechanical seal assembly 4; The bottom of 18 is connected to the upper guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com